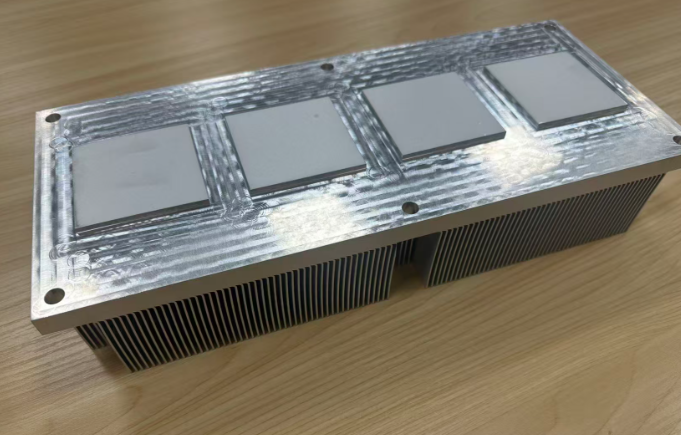

Design and Application of High-Power TEC Heat Sinks

Abstract Design and Application of High-Power TEC Heat Sinks – Catering to Temperature Control Requirements of Medical Precision Instruments.With the rapid development of the medical industry and precision instrument field, the sensitivity and precision requirements of equipment for temperature control have significantly increased. Especially in scenarios where the temperature needs to be lower than the […]

How to choose the interface materials of liquid cooled plates

As the core of AI computing power, NVIDIA’s H100 GPU generates extremely high heat density—like a “heat bomb”—when operating at full load with 750W.The importance of interface materials in high-power liquid cooled plates. If the thermal interface material is improperly selected, the core temperature may exceed 120°C, triggering immediate thermal throttling and even shortening the […]

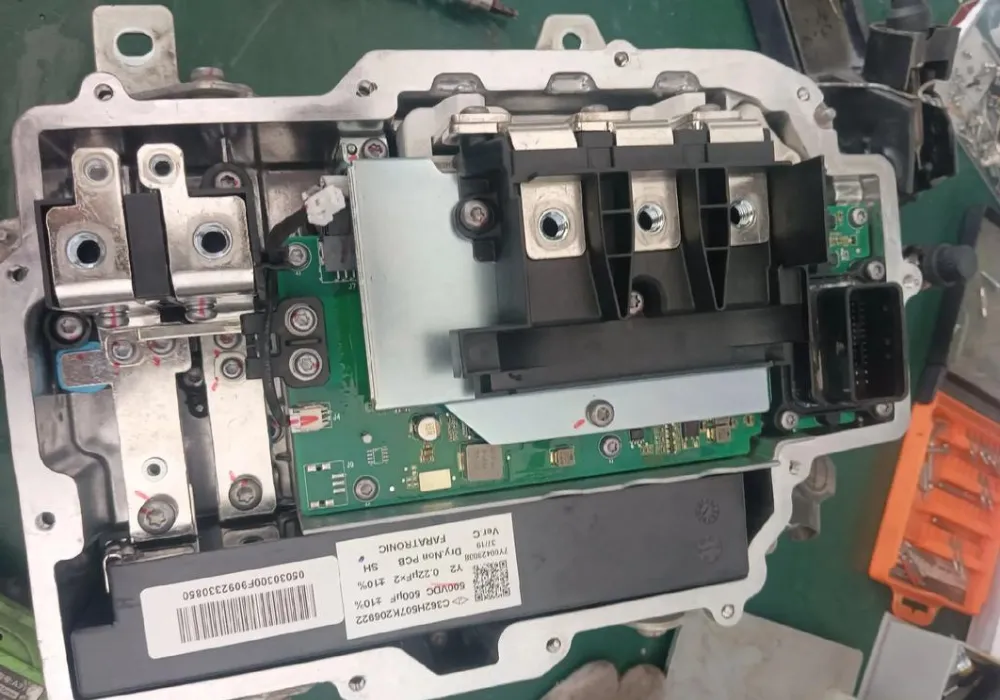

Applications of IGBT: An Expert Guide

Have you ever wondered what makes an electric car accelerate so smoothly? Or how a solar panel efficiently converts sunlight into electricity for your home? Behind these modern marvels, there is a powerful and often overlooked component working silently: the Insulated Gate Bipolar Transistor, or IGBT. This tiny semiconductor is the workhorse of modern power […]

What Is a Direct Liquid Cooling System?

Have you ever noticed how hot your phone or laptop gets when you’re gaming or streaming? Now, try to imagine a building packed with thousands of super-powered computers. These machines are running the artificial intelligence and complex calculations that shape our world. The heat they produce is incredible. For a long time, we’ve fought this […]

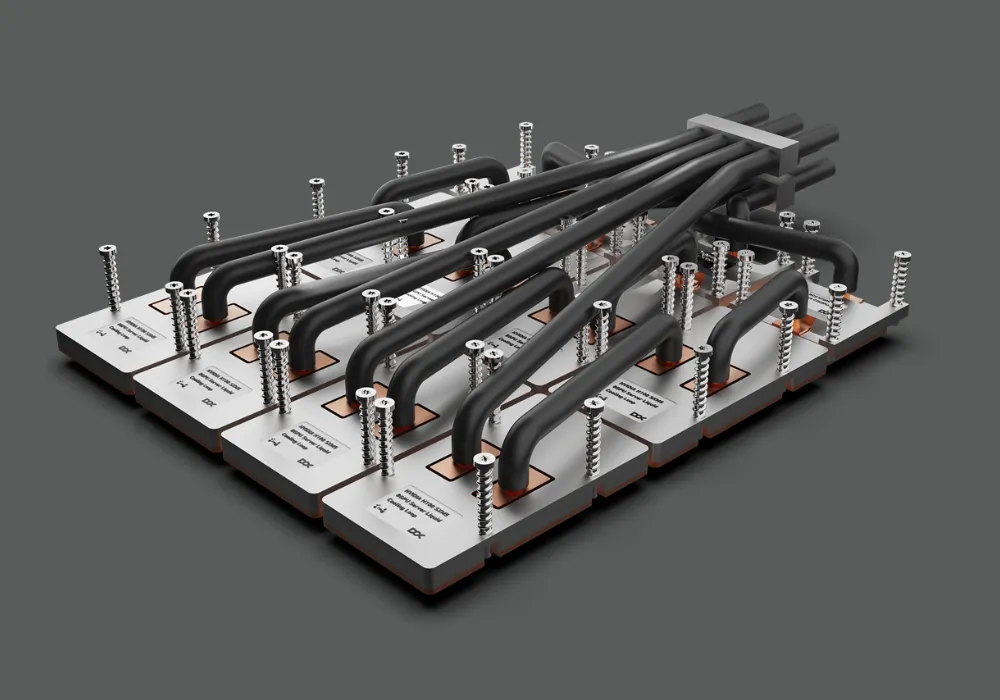

Design and 500W-Level Heat Dissipation Performance Verification of M-Type Copper Tube-Embedded Four-Channel Liquid Cooling Plate

Abstract To address the heat dissipation requirements of 500W high-power devices, this study designs an M-type copper tube-embedded four-channel liquid cooling plate. Based on a base plate dimension of 127mm×152mm×15.2mm, four sets of M-type flow channels are constructed using copper tubes with an outer diameter of 9.52mm and a wall thickness of 1.24mm. Combined with […]

1kW Copper Tube Embedded Liquid Cooling Plate

Abstract To meet the efficient heat dissipation requirements of 1kW high-power electronic devices (such as high-power server CPUs and industrial inverter modules), this paper designs a six-channel copper tube embedded liquid cooling plate. Based on a 6063-T5 aluminum alloy base plate with dimensions of 177.8mm×152mm×14mm, six groups of parallel flow channels are constructed using copper […]

What Are Big Heat Sinks and When Do You Need One for High-Power Cooling?

Have you ever stood next to a large solar inverter or an EV fast-charging station and felt the warm air being pushed out? That warmth is waste heat, and a lot of it. In our high-power world, we are generating more heat than ever before. A tiny processor in your phone might need a small […]

What is an IGBT? The Ultimate Guide to This Powerhouse Component

Have you ever stopped to think about the silent revolution happening all around us? It’s in the smooth, instant acceleration of an electric vehicle, the seamless flow of energy from a solar panel into the grid, and the tireless precision of an industrial robot. A single, unsung hero working behind the scenes—a powerful electronic switch—makes […]

Skived vs. Extruded Heat Sink: Which Thermal Solution is Right for You?

Have you ever wondered how your electric vehicle can unleash immense power without its battery overheating, or how massive data centers powering our digital world run 24/7 without melting down? The answer isn’t magic; it’s a masterpiece of thermal engineering. At the heart of this process is one of the most critical decisions an engineer […]