Leading Custom Heat sink Manufacturer in China

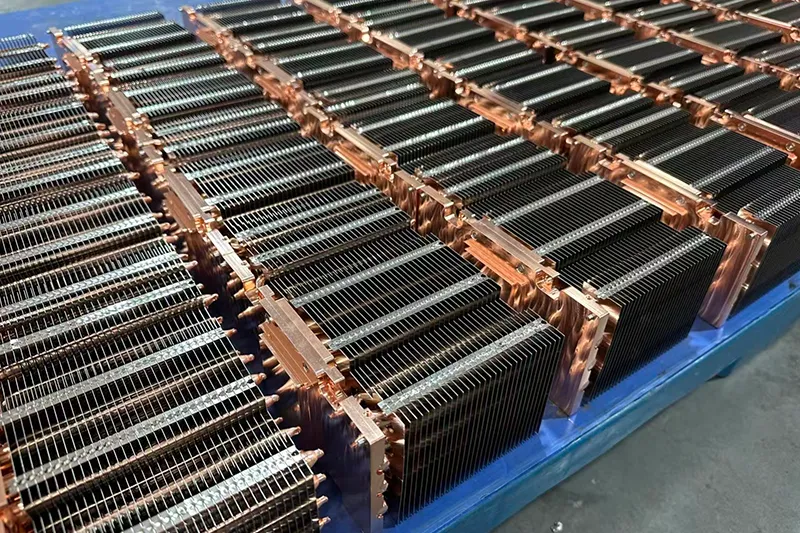

As a dedicated heat sink manufacturer, Kenfa Tech handles everything from initial design and thermal simulations to full production and rigorous testing. We work with designers, engineers, and procurement teams to create reliable heat sink for your high-power devices.

Your Trusted Heatsink Manufacturer Partner

Kenfa Tech stands as a national high-tech enterprise with over 10 years crafting high-power heat sinks. We deliver full-cycle services from thermal design and simulations to production and testing, helping designers, engineers, and buyers tackle overheating in lasers, medical devices, solar systems, and AI centers. Our approach cuts costs while boosting reliability through smart engineering and quick iterations.

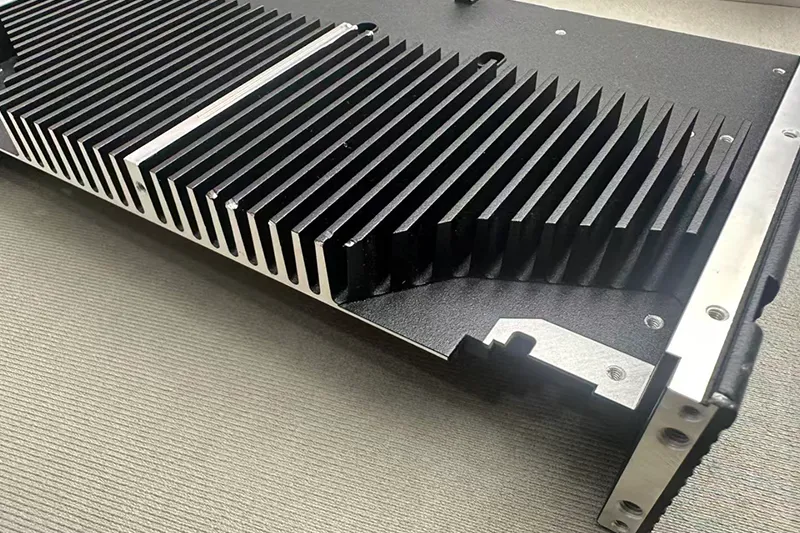

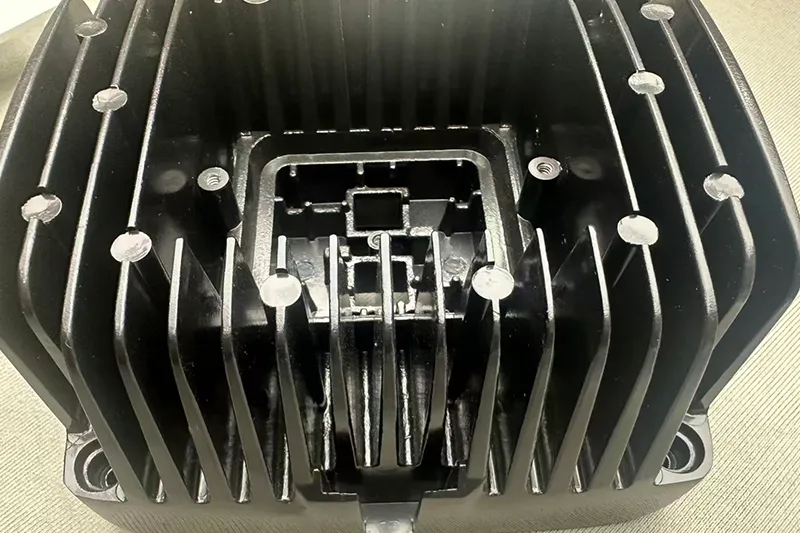

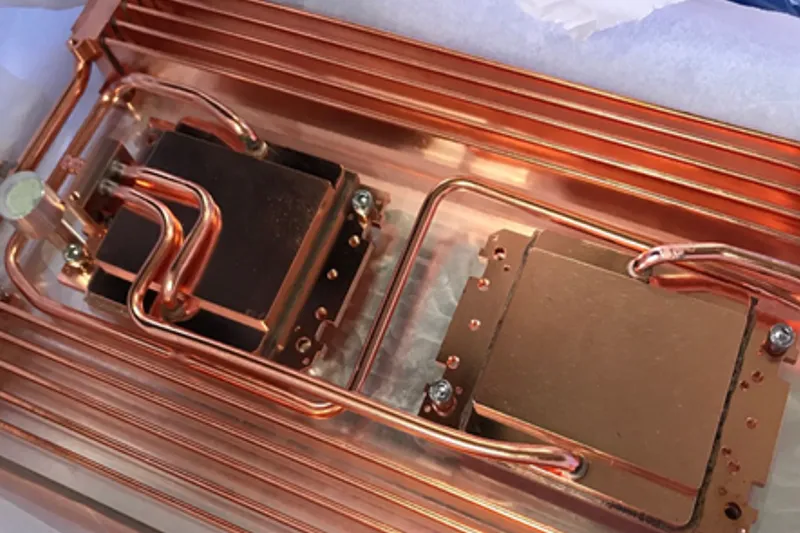

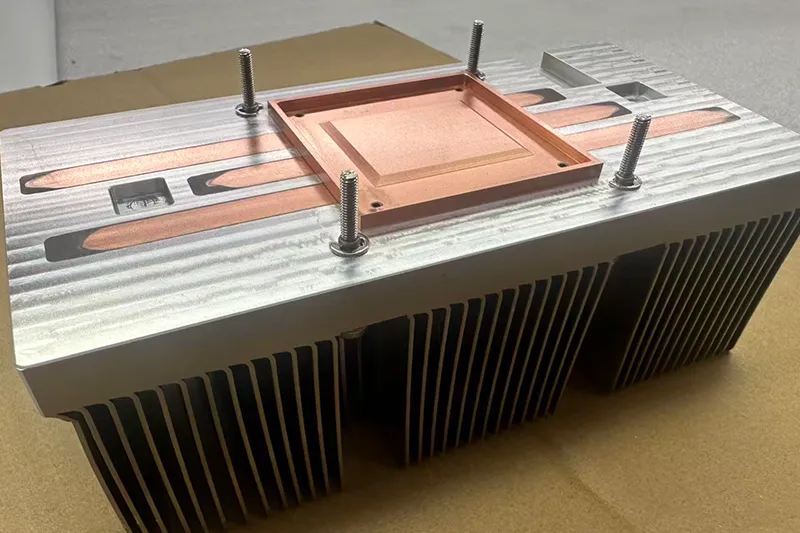

We master a full suite of production methods like CNC machining, extrusion, die casting, cold forging, skiving fin, brazing, soldering, and bonded fins to fit any heat sink project scale. This lets us create aluminum or copper heat sinks that outperform standards in tight spaces or extreme heat.

We master a full suite of production methods like CNC machining, extrusion, die casting, cold forging, skiving, brazing, soldering, and bonded fins to fit any heat sink project scale. This lets us create aluminum or copper heatsinks that outperform standards in tight spaces or extreme heat.

Types of Heat sink Processes at KenfaTech

Choose from our range of heatsink manufacturing methods,each designed

to meet specific user needs like cost savings, high thermal performance, or custom fits.

Quality Control at Kenfa Tech

At Kenfa Tech, quality shapes every heatsink we build. Our strict checks ensure each piece delivers strong cooling, lasts in tough conditions, and fits your needs without fail. We test for thermal efficiency, build strength, and surface finish to catch issues early and keep standards high.

We know quality slips and late shipments hurt in this field. So we use tight production rules and smart supply chains to fix that. Our plans match your deadlines, so you get reliable heatsinks on time, every time.

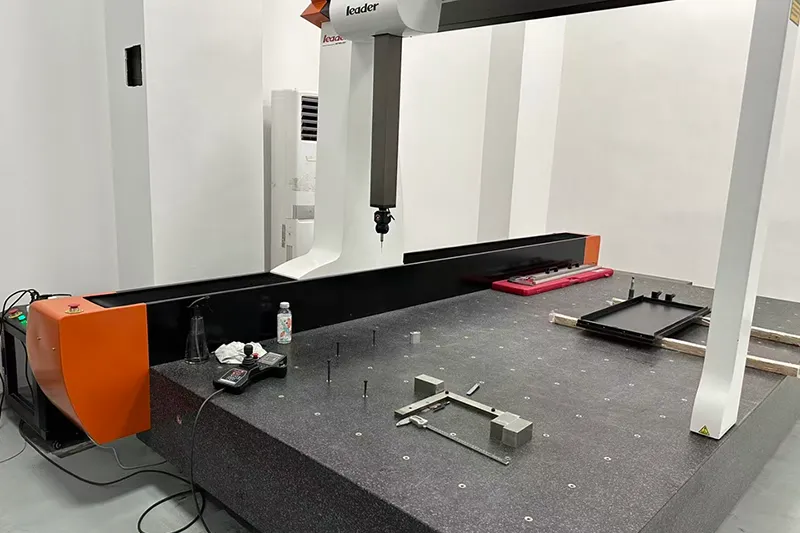

Advanced Inspection Equipments

We rely on top gear like spectrometers for material makeup, CMMs for 3D shapes, and height gauges for basic sizes. This spots flaws fast in aluminum or copper heatsinks.

Comprehensive Testing Procedures

Every heatsink faces material scans, strength pulls, corrosion soaks, and function runs. These confirm your custom heat sinks handle heat loads, resist wear, and stay sealed if needed.

Proven Quality Standards

Content: Our ISO9001, ISO14001, and IATF16949 seals mean consistent work. If a heatsink falls short, we remake it free. All parts get a final look before shipping.

Heat sink Solutions for Your Industry

We tailor heatsinks to handle heat in demanding fields, from servers to AI centers.

Servers

Automotive

Industrial Manufacturing

Servers

Medical

AI Computing Centers

How To Select The Right Heat Sink For Your Electronic Device?

Overal, heat sinks plaly a crucial role in maintainingthe temperature of electronic devices within safe operating limits,preventing damage to components caused byaxcasiwe heat. They are widely used in icel,Laser Eouipmant, MedicalEquipment, Photovoltalic inverter, 58 implamentation,Batery packng cooung, and vanous otner electronic systems that require effective heat management.

Why Choose Kenfa Tech as Your Heatsink Manufacturer

controls, and efficient processes that solve thermal challenges for engineers and buyers

Over 10 Years in Heatsink Manufacturing

Our team brings deep knowledge from serving global clients in lasers, medical, and power systems, ensuring reliable custom heat sinks that fit your exact needs.

ISO and IATF Certified Quality

We hold ISO9001, ISO14001, and IATF16949 standards, so every aluminum or copper heatsink meets high safety and environmental rules, with full reports on request.

Advanced Factory Setup

Our 10,000 sq ft facility runs CNC, extrusion, and testing lines to handle large orders of custom heat sinks without delays, even in busy times.

Fast Sample Delivery

Get prototypes in weeks after design tweaks, helping engineers test copper or aluminum heatsinks quickly to speed up your product launch.

Thermal Simulation and Advice

Our engineers run simulations to predict performance, offering tips on heat pipe or skived fin heatsinks to avoid overheating in your setups.

Cost-Effective Sourcing

Strong ties with suppliers cut costs on materials for bonded fin or brazing heatsinks, passing savings to you while keeping quality high.