Heat Pipe Assembly

Heat Sink

Heat pipe is a kind of efficient heat transfer material, through the design of different structures, and the combination of different processes of heat sink fin, can provide customers with efficient cooling solutions

What Is The Heat Pipe?

Heat pipe is an efficient heat conduction material, which can transfer a large amount of heat through the internal capillary structure, and circulate the heat from one end of low temperature to the other end of high temperature to achieve efficient heat transfer effect.Through the design of different structures, and the combination of different processes of heat sink fin, can provide customers with efficient cooling solutions.

How to Make A Heat Pipe?

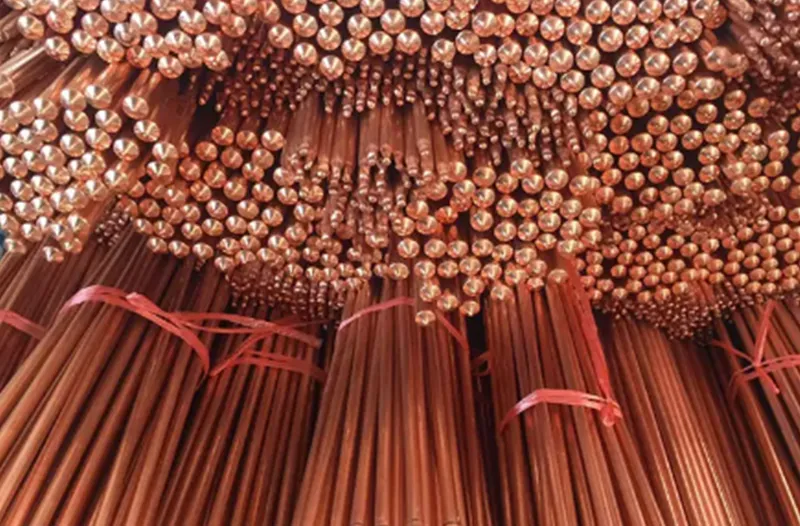

The diameter of the heat pipe is usually 4,5,6,6.5,8,9.5,10,10.5, and 12mm. So the corresponding copper tube is these diameters. These specifications of copper pipe after cleaning, oil, and then do passivation and antioxidant treatment.The copper tube is sealed at one end by a high speed shrinking machine.And of course there’s always the process of laser welding, so there’s no risk of leakage at one end of the copper tube.

A 3mm diameter stainless steel rod was inserted into the finished copper tube, taking the 6mm diameter copper tube as an example.Then the copper powder is poured into the copper tube, and after mechanical vibration, the copper powder is tightly combined with the copper tube wall .These copper tubes with copper powder inside were heated to 800 degrees in a vacuum furnace. Under the high temperature, the copper powder and the copper tube walls were tightly bonded together.

Let the vacuum oven slowly cool down, and take out the copper tube. At this time, remove the stainless steel rod in the center, and inject pure water containing alcohol into the copper tube according to the power calculation of the customer’s demand.The air inside the copper pipe injected with water is pumped into a vacuum by a vacuum machine, and then the other end of the copper pipe is welded and closed by a laser welding machine, so that a copper pipe containing liquid in the vacuum state is formed, which we call a heat pipe.

How Does A Heat Pipe Work?

Heat pipe is a kind of heat conversion of liquid inside under capillary action under closed and vacuum conditions. Because the inside of the heat pipe is a vacuum state, it can work under specific temperature conditions, generally about 35 degrees. When the liquid is heated, the liquid state at this time is water vapor, and a large amount of heat will be taken away. At this time, the whole heat pipe is equivalent to a steam chamber, and the heat is evenly diffused inside the heat pipe.

When the other end of the heat pipe meets the forced convection of the fan or the natural convection of the surface area of the object, the temperature will drop at this time, and the water vapor will solidify into the state of water droplets. Under the action of gravity, these water droplets will be absorbed by the capillary structure of the copper powder inside the copper pipe, and then reflux. At this time, the liquid returns to its original position, and at this time, it encounters a large amount of heat, and again the liquid evaporates, and the cycle is repeated so as to achieve the purpose of transferring heat from one place to another. This is the efficient heat transfer effect that we want.

The Advantage of High Thermal Conductivity of Heat Pipe Compared With Other Materials.

– Die-cast aluminum alloy such as ADC12 can achieve a thermal conductivity of about (96-110)W/(m K). -Cold forging aluminum generally uses 1050, 1070 series, its thermal conductivity is 235W/(m K).

-Extrusion aluminum material is generally 6061 or 6063 , thermal conductivity of 210W/(m K). -The material of copper is generally C1100 and its thermal conductivity is 383.5W/(m K).

– The thermal conductivity of a heat pipe is generally 5000 to 25000W/(m K).Of course, different lengths of heat pipes have different conduction efficiency.

Important Characteristics of Heat Pipes

In a limited space, the heat can be transferred to other places, and then the heat is dissipated by forced convection or natural convection, such as a laptop computer, the CPU in the center of the computer motherboard, the heat must be transferred to the edge of the notebook, and then the heat is dissipated by the fan.

The application and development of heat pipe has more than 50 years of history, so it is a very mature process and low price. It is a very efficient and cost-effective heat dissipation scheme.The early heat pipe is a heat dissipation scheme for space satellites, so the life requirements are very strict. In general, the heat conduction ability of the heat pipe will not be degraded in the long working state, and the life is generally greater than 20 years.

The high performance heat transfer coefficient is more than 20 times that of copper and aluminum metal materials, which can quickly conduct the heat out, reduce the chip temperature, and ensure the stable operation of the system.

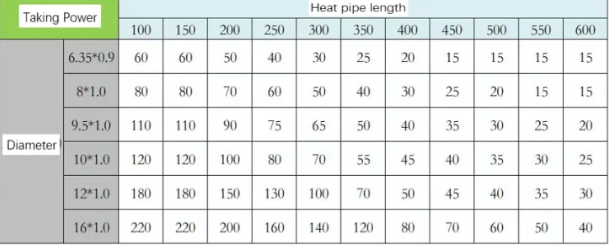

The Conduction Performance of The Heat Pipe

That is the maximum heat that can be taken away, depends on the length and diameter of the heat pipe, of course, and the shape is also related, usually bending once, the conduction performance is reduced by 5%, and the general bending R Angle is greater than 1.5 times the diameter of the heat pipe.

Heat Pipe Heat Sinks Applied In Different Fields

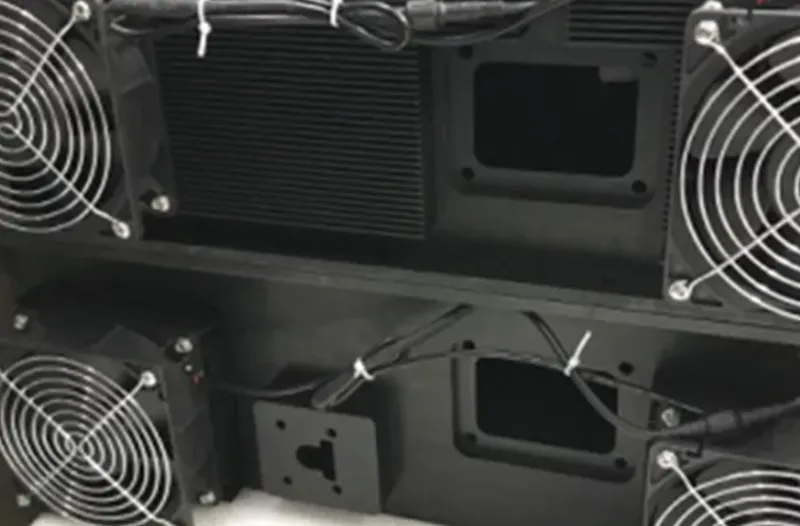

Heat Pipe Heat Sink Used In The Battery Pack for Cooling Solution.

The high thermal conductivity of the heat pipe is used to conduct the heat of the battery module to the edge of the heat sink, and then the heat is dissipated by the fan. Especially suitable for the scheme of waterproof grade greater than IP68, of course, the heat sink can be generally die-casting process of the heat sink or the profile process of the heat sink, for the special shape of the battery pack thermal management needs, sometimes need to use CNC process making .This is because heat pipe heat sink are increasingly being adopted by design engineers.

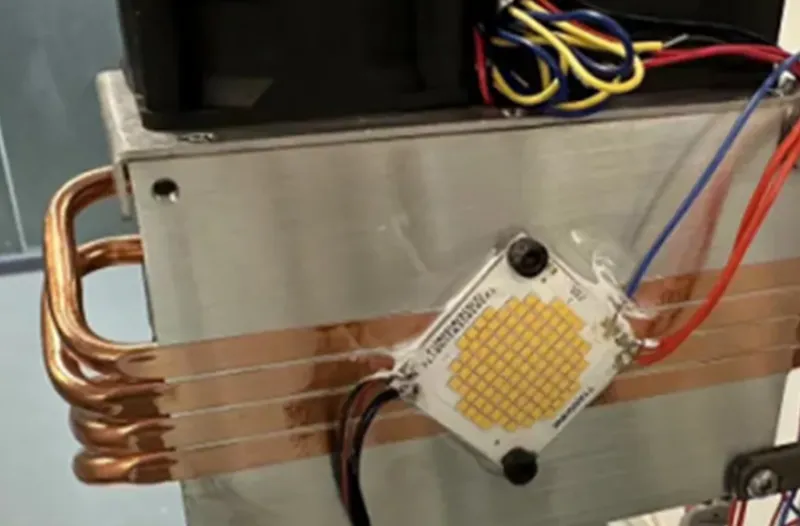

Heat Pipe Heat Sink Used In The LED Lighting for Cooling Solution.

High power LED lighting fixtures also require heat sinks with good heat dissipation performance, especially for high power density LED light sources, which usually exceed 500W and some may exceed 1000W. At this time, high-power heat pipe heat sinks are needed to solve this heat dissipation problem, transferring high-density heat to Fin chips and utilizing the forced convection characteristics of fans to dissipate heat into the air. Of course, The design of this type of lighting fixture requires engineers to fully understand the performance of the heat pipe, such as the bending angle R, horizontal usage, and gravity direction usage conditions. These parameters are very important. When you have such a demand, be sure to communicate with our engineers.High power stage lights, LED plant lights, UL ultraviolet lamps, etc. all use such heat pipe heat sink.

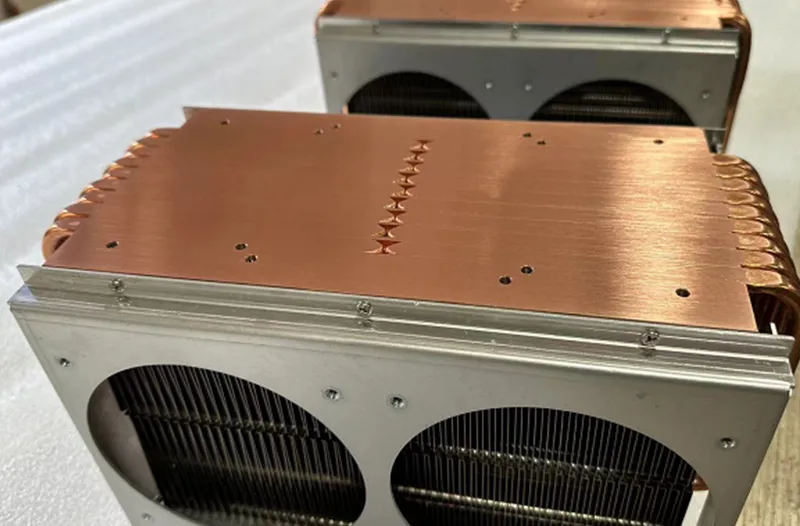

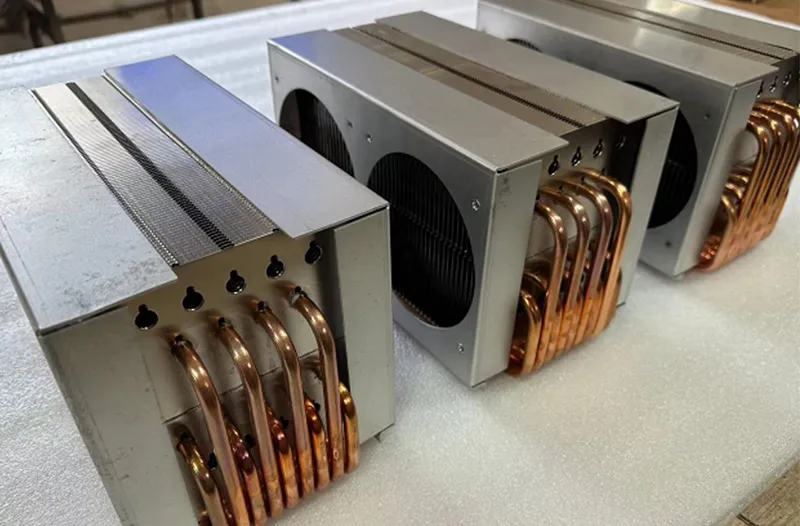

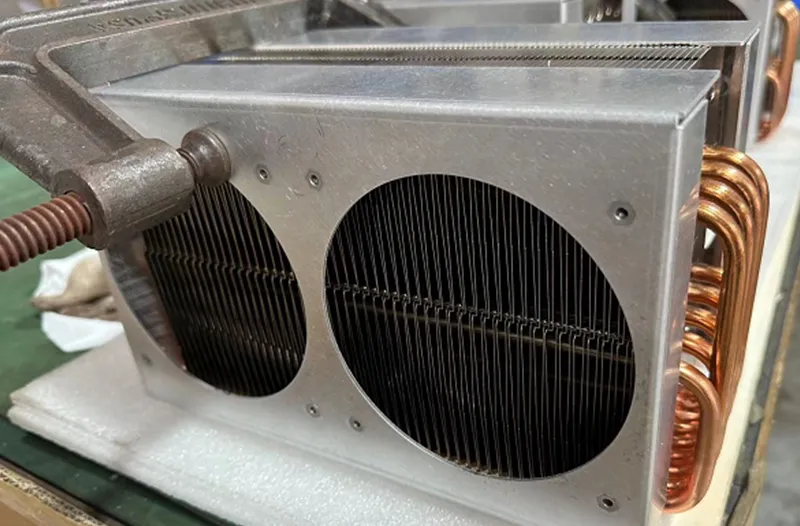

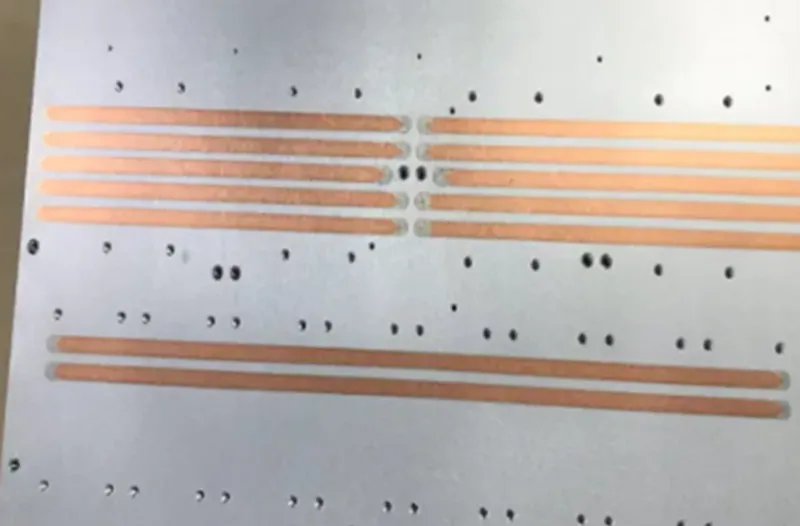

Heat Pipe Heat Sink Used In Photovoltaic Inverter And IGBT for Cooling Solution.

Photovoltaic inverter and IGBT are high-power chips, they will make a lot of heat in the process of operation, because their heating area is relatively concentrated, so the use of heat pipe good conductivity and thermal diffusivity, can effectively spread and conduct the heat to the bottom plate of the heat sink, and then use the fin of the heat sink to disperse the heat.

Skived fin heat sink process and heat pipe is the most effective solution to solve the heat dissipation of this kind of high-power chipsets.However, it should be noted that the layout of the heat pipe needs to be optimized. At the same time, it is necessary to consider the use of outdoor conditions and the freezing of liquid inside the heat pipe, so as to avoid the heat pipe expansion, which makes the heat pipe fail and damage the components

How Do You Design A Heat Pipe or What Do You Need to Pay Attention to When Designing A Heat Pipe?

– Design a heat pipe, engineers need to pay attention to the selection of the appropriate heat pipe diameter and length, and whether the heat pipe is bent .

– The two ports of the heat pipe have the length limit of the invalid end and the effective end due to the process.

– In some special cases, such as the heat pipe needs to be flattened, such as the heat pipe module of a laptop computer, how to calculate its thickness and width after flattening?

– The wall thickness of the heat pipe usually has several specifications due to the need for processing. If it is not necessary to process the heat pipe, the wall thickness can be designed as 0.4mm. If processing is required, especially when the bottom plate groove of the heat sink is tightly fitted, the heat pipe wall thickness at this time is 0.9mm so that the heat pipe does not fail after processing. So the parameters in the following chart can be used as a reference value for our subsequent design.