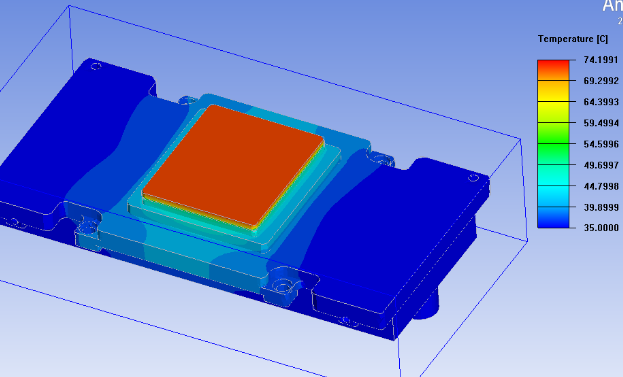

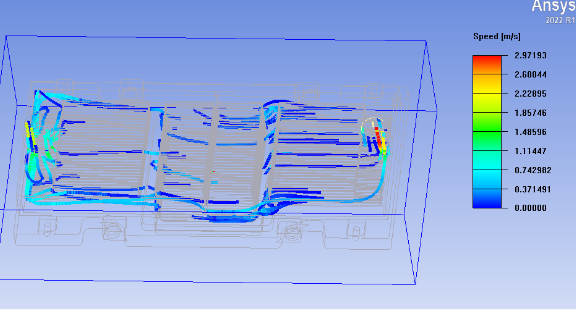

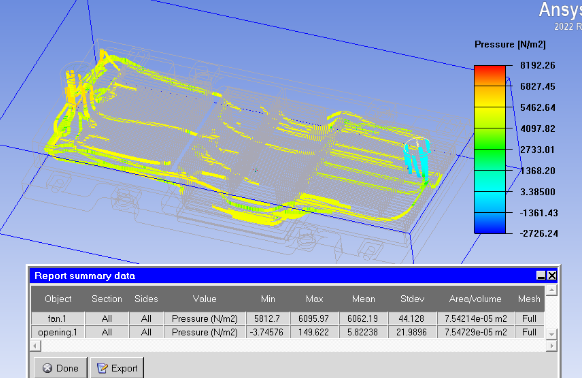

As the core of AI computing power, NVIDIA’s H100 GPU generates extremely high heat density—like a “heat bomb”—when operating at full load with 750W.The importance of interface materials in high-power liquid cooled plates. If the thermal interface material is improperly selected, the core temperature may exceed 120°C, triggering immediate thermal throttling and even shortening the hardware lifespan. From conventional thermal pads to high-performance graphite sheets, different materials vary significantly in thermal conductivity and application suitability. Accurate material selection is crucial for the H100 to stably deliver its computing power. Notably, thermal simulation analysis via Ansys software further underscores the irreplaceable role of thermal interface materials: for a pure copper liquid cold plate with dimensions 80mm × 145mm × 20mm (height), the simulation reveals that the local temperature at the center is extremely high, and heat cannot be effectively transferred to the two sides of the cold plate. This directly proves that thermal sheets are indispensable for bridging the heat transfer gap between the H100 core and the cooling system.

I. Conventional Thermal Pads (1-12W/m·K): The “Basic Line of Defense” for H100 Heat Dissipation

Conventional thermal pads are based on silicone, with their performance adjusted by adding thermal conductive fillers. Covering the range of 1-12W/m·K, they serve as “entry-level to advanced options” for H100 heat dissipation systems, and their suitability varies with thermal conductivity gradients:

1. Low Thermal Conductivity Range (1-3W/m·K): Emergency Use Only, Not for Primary Cooling

These thermal pads are mostly entry-level products, with thermal efficiency only meeting the basic needs of “filling gaps and isolating air” (air has a thermal conductivity of just 0.026W/m·K). When used on the H100, even during low-load startup (power below 200W), they can only transfer a small amount of heat slowly. Once the power climbs to 750W, excessive thermal resistance traps heat at the core—exacerbating the “central overheating” issue observed in the Ansys simulation of the copper cold plate—and the core temperature may exceed 100°C within 10 minutes, triggering throttling. They are only suitable for auxiliary heat dissipation of low-power components around the H100 (such as power supply modules) and must never be used in the core area.

2. Medium Thermal Conductivity Range (4-6W/m·K): Usable for Medium Loads, Struggles at Full Load

After adding fillers like aluminum nitride and aluminum oxide, these pads have 30% lower thermal resistance than low-conductivity models, making them suitable for “light to moderate tasks” of the H100. For example, during small-scale AI inference (power 300-400W), they can transfer core heat to the heatsink, maintaining the temperature at around 95°C. However, under 750W full load, the heat transfer speed cannot keep up with heat generation. Similar to the Ansys simulation result, heat accumulates at the center, and after 30 minutes, the core temperature will rise above 110°C, with even higher temperatures at local hotspots (such as areas with concentrated computing cores). Long-term operation may lead to degradation of circuit performance. They are only suitable for temporary non-full-load scenarios of the H100 and cannot meet the needs of high-intensity tasks.

3. High Thermal Conductivity Range (7-12W/m·K): The “Main Player” for 750W Full Load

These pads use high-purity composite fillers (such as graphene microflakes + boron nitride) and feature optimized conformability (20%-40% compression ratio), allowing them to tightly fill micro-gaps between the H100 core and the copper cold plate—effectively addressing the “heat transfer bottleneck” identified in the Ansys simulation. Under 750W full load, they can quickly transfer core heat to the cold plate, guiding heat to spread to both sides rather than accumulating at the center, thus stabilizing the core temperature within the safe range of 85-95°C, with a surface temperature difference controlled within 5°C. Additionally, their electrical insulation (insulation resistance ≥10^9Ω·cm) prevents short circuits between the H100 and the cold plate, while their cost is lower than that of indium sheets and graphite sheets. They are the cost-effective first choice for mass-produced H100 applications.

II. Indium Sheets (81-86W/m·K): A High-Thermal-Conductivity but “Niche” Option

As a metallic thermal interface material, indium sheets have much higher thermal conductivity than conventional pads and excellent ductility (can be compressed to 0.03mm for “seamless bonding”). For the H100 and its copper cold plate, they excel at solving the “central heat accumulation” problem highlighted by Ansys:

•Core Advantages: With a high thermal conductivity of 81-86W/m·K, indium sheets can transfer concentrated heat from the H100 core to the cold plate at “millisecond speed,” with thermal resistance only 1/5 that of 12W/m·K pads. This ensures heat is rapidly diverted to both sides of the cold plate, controlling the temperature difference between the core and the cold plate within 3°C. For scenarios requiring extreme temperature stability (such as H100 supercomputing nodes), they further reduce temperature fluctuations and minimize hardware wear caused by thermal stress.

•Application Limitations: Firstly, the cost is high—their unit price is 5-8 times that of 12W/m·K pads, and large-scale deployment will significantly increase hardware costs. Secondly, they are prone to oxidation; an oxide layer may form within 24 hours of exposure to air, reducing thermal conductivity by 30% and requiring additional coating for oxidation protection. Thirdly, installation requirements are strict—indium sheets have low hardness, and if there are tiny protrusions on the H100 core or cold plate surface, deformation may occur during installation, reversing the heat transfer improvement and reintroducing local overheating. They are only suitable for niche scenarios with high budgets and high precision and cannot become a mainstream choice.

III. Graphite Sheets (800-2500W/m·K): The Key to “Hotspot Elimination” for the H100

Graphite sheets, with their characteristics of “high lateral thermal conductivity + ultra-thin form,” are the “heat spreading champions” for H100 heat dissipation—especially valuable for complementing the copper cold plate (whose limited lateral heat transfer was exposed in the Ansys simulation). Their core value is to work with thermal pads to accelerate heat dispersion across the cold plate, avoiding central overheating. Different types of graphite sheets vary significantly in suitability:

1. Natural Graphite Sheets (800-1200W/m·K): Cost-Effective Auxiliary for Heat Spreading

Natural graphite sheets have a lateral thermal conductivity 2-3 times that of copper, enabling them to quickly disperse heat from the H100’s central hotspots (identified in the Ansys simulation) across the entire cold plate surface. When paired with 10-12W/m·K thermal pads (which handle vertical heat transfer from the core to the cold plate), natural graphite sheets guide heat to the cold plate’s sides, reducing local hotspot temperatures by 10-15°C under 750W full load. Their cost is only 1/3 that of synthetic graphite sheets, making them the preferred heat-spreading option for mass-produced H100 systems.

2. Synthetic Graphite Sheets (1500-2000W/m·K): The Main Force for Heat Spreading Under High Loads

Synthetic graphite sheets, produced via high-temperature graphitization, have a vertical thermal conductivity increased to 30-50W/m·K and stronger lateral heat-spreading capabilities. Their ultra-thin design (0.01-0.1mm) fits perfectly between the H100 core and the copper cold plate, addressing the cold plate’s inherent heat dispersion limitation. During long-term 750W full-load operation (such as 24/7 AI training), they work with high-thermal-conductivity pads to keep core temperature fluctuations within ±2°C, ensuring heat is evenly distributed across the cold plate and eliminating the risk of central overheating. They are suitable for high-end server scenarios requiring strict stability, but their cost is 3-5 times that of natural graphite sheets, requiring a balance between budget and needs.

3. Nano-Composite Graphite Sheets (1800-2500W/m·K): The “Technical Benchmark” for Extreme Scenarios

These graphite sheets are manufactured through high-temperature expansion + ultrasonic vibration processes, achieving peak thermal conductivity—their lateral heat-spreading speed is 8-10 times that of copper, far exceeding the cold plate’s native capabilities. They are resistant to high and low temperatures (-50°C to 200°C) with no performance degradation, making them ideal for eliminating even the most severe central hotspots in the H100. However, the manufacturing process is extremely complex, and the cost is 2-3 times that of synthetic graphite sheets. Additionally, they can only be produced to order—currently, they are only used in special scenarios such as military-grade and supercomputing-grade H100 applications and are completely unsuitable for civilian or commercial markets.

IV. Ultimate Selection Logic for H100 (750W) Heat Dissipation

1.First Choice for Mass-Produced Cost-Effectiveness: 10-12W/m·K high-thermal-conductivity pads (for vertical core-to-cold-plate heat transfer) + natural graphite sheets (for lateral cold-plate heat spreading). This combination directly addresses the “central overheating” issue of copper cold plates (as shown in Ansys simulations), meets over 90% of H100 commercial scenarios (such as AI inference servers and data center nodes), and balances heat dissipation efficiency and cost.

2.Adaptation for High-Precision Scenarios: 12W/m·K pads + synthetic graphite sheets (suitable for AI training scenarios sensitive to temperature fluctuations) or indium sheets (suitable for supercomputing-grade high-precision needs), requiring acceptance of a 3-5x cost increase to achieve near-perfect heat distribution.

3.Special Extreme Scenarios: Nano-composite graphite sheets + indium sheets, only used for customized, high-budget special needs (such as military computing units), and not a mainstream market direction.

For the H100, there is no “absolutely best” heat dissipation material—only the “most suitable” combination. As the Ansys simulation of copper cold plates confirms, thermal sheets are the critical link to solving heat transfer bottlenecks. By balancing actual computing power needs, budget costs, and stability requirements between thermal pads and graphite sheets, the powerful 750W computing power of the H100 can be stably unleashed.