Abstract

Design and Application of High-Power TEC Heat Sinks – Catering to Temperature Control Requirements of Medical Precision Instruments.With the rapid development of the medical industry and precision instrument field, the sensitivity and precision requirements of equipment for temperature control have significantly increased. Especially in scenarios where the temperature needs to be lower than the ambient temperature and the control precision must be maintained within ±1℃ (such as the test paper testing process of medical instrument analyzers), the heat dissipation efficiency of high-power thermoelectric coolers (TEC) has become a core factor affecting the temperature control effect. To address this demand, this paper proposes a split-type heat sink design scheme consisting of a “cold-side heat sink” and a “hot-side heat sink”. It clearly specifies that the cold-side heat sink adopts the profile extrusion process to ensure surface smoothness and avoid condensation and icing, while the hot-side heat sink uses the high-density skived fin process to enhance heat dissipation capacity. Additionally, gaps are reserved and filled with foam to solve the problem of cross-flow between the cold and hot sides. Combined with an application case of a 200×150×80mm skived fin heat sink, it is verified that this scheme can effectively meet the heat dissipation requirements of 4 sets of 50W TEC modules, providing reliable support for the temperature control of medical precision instruments.

1. Introduction

In medical testing instruments (such as biochemical analyzers and immunoassays), key processes like test paper reactions and sample preservation have extremely high requirements for temperature stability. Not only does the temperature need to be controlled within a range lower than the ambient temperature, but also the precision must be maintained within ±1℃. Under this demand, TEC is widely used due to its advantages of precise temperature control and fast response speed. However, high-power TEC generates a large amount of heat during operation. If the heat on the hot side is not dissipated in a timely manner or condensation and icing occur on the cold side, it will directly lead to a decrease in temperature control precision and even damage the core components of the instrument.

Traditional TEC heat sink designs often adopt a single structure and process, making it difficult to simultaneously meet the dual requirements of “condensation prevention on the cold side” and “high-efficiency heat dissipation on the hot side”. Therefore, based on the temperature control pain points of medical precision instruments, this paper designs a split-type high-power TEC heat sink. Through process selection, structural optimization, and case verification, it provides design ideas and practical references for similar applications.

2. Core Principles and Scheme for High-Power TEC Heat Sink Design

2.1 Core Design Principles

1.Condensation and Icing Prevention Principle: The cold-side heat sink is in direct contact with the cold end of the TEC and the temperature-controlled area. If the surface is uneven, water vapor in the air is likely to condense into water droplets on the cold side, and even freeze in a low-temperature environment, which affects heat conduction efficiency and instrument safety. Therefore, the cold side must ensure an extremely high surface smoothness.

2.High-Efficiency Heat Dissipation Principle: When the TEC is in operation, the hot end generates a large amount of heat equivalent to the cooling capacity (including heat converted from input power). If the heat on the hot side is not dissipated in a timely manner, the temperature difference between the cold and hot ends of the TEC will decrease, and the cooling efficiency will drop sharply. Therefore, the hot side must adopt a structure and process with high heat dissipation efficiency.

3.Cold-Hot Isolation Principle:If the cold side and the hot side are in direct contact or there is air cross-flow, it will cause mutual interference between cold and heat exchange and damage the stability of temperature control. Therefore, structural design is required to block the heat cross-flow and air circulation between the cold and hot sides.

2.2 Split-Type Heat Sink Design Scheme

Based on the above principles, this paper proposes a split-type heat sink design, dividing the overall structure into two parts: the “cold-side heat sink” and the “hot-side heat sink”, which adopt differentiated processes and structural designs respectively:

2.2.1 Cold-Side Heat Sink: Profile Extrusion Process Ensures Surface Smoothness

The cold-side heat sink acts directly on the cold end of the TEC, and its core requirement is to prevent condensation and icing. Therefore, the cold side is processed using the profile extrusion heat sink process. This process can achieve extremely low surface roughness (Ra ≤ 0.8μm) through extrusion molding and precision grinding, forming a smooth and flat surface.

A smooth surface can reduce water vapor adhesion points, and even in a low-temperature environment, it can reduce the probability of water droplet condensation. If the ambient humidity is high, the smooth surface also facilitates the natural sliding of water droplets, avoiding long-term accumulation and ice formation, thus ensuring the heat conduction efficiency between the cold end of the TEC and the heat sink and maintaining temperature control precision.

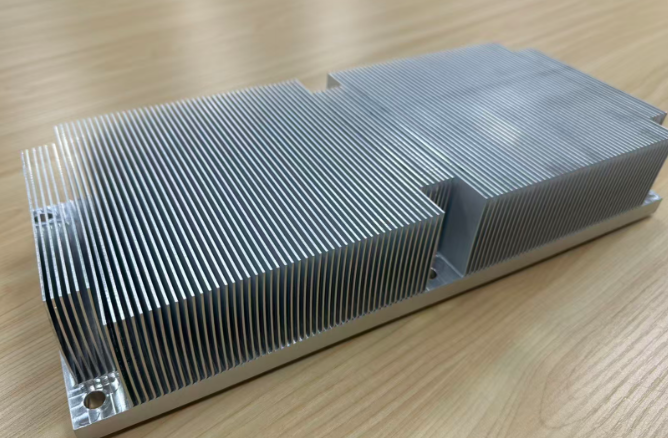

2.2.2 Hot-Side Heat Sink: Skived Fin Process Enhances Heat Dissipation Capacity

The hot-side heat sink needs to quickly dissipate a large amount of heat generated at the hot end of the TEC, and its core requirement is to maximize the heat dissipation area and heat exchange efficiency. Therefore, the hot side is processed using the high-density skived fin process. This process forms dense fins directly on the heat sink base plate through mechanical cutting. Compared with traditional aluminum extrusion profiles, it can achieve smaller fin spacing and higher fin height, significantly increasing the heat dissipation area.

At the same time, the skived fin process ensures that the fins and the base plate form an integrated structure, avoiding contact thermal resistance caused by welding or assembly, and further optimizing heat conduction efficiency. In the design of this paper, the fin spacing of the hot-side skived fin heat sink can be controlled within 2mm, and the maximum fin height can reach 120mm, which can be flexibly adjusted according to the TEC power to meet high-power heat dissipation requirements.

2.2.3 Cold-Hot Isolation Design: Gap Reservation and Foam Filling

To avoid cross-flow interference between the low temperature of the cold side and the high temperature of the hot side, a fixed gap of 10~15mm is reserved between the cold-side and hot-side heat sinks, and the gap is filled with foam material with high temperature resistance and low thermal conductivity. This design can achieve three effects:

•Physical Isolation: Blocks direct contact between the cold and hot sides, avoiding heat conduction cross-flow.

•Air Blocking: Filling the gap can prevent convective exchange between cold and hot air, reducing heat interference.

•Buffer Protection: The foam material has a certain elasticity, which can alleviate slight vibrations during TEC operation and protect the connection stability between the heat sink and the TEC module.

3. Application Case Verification

3.1 Case Background

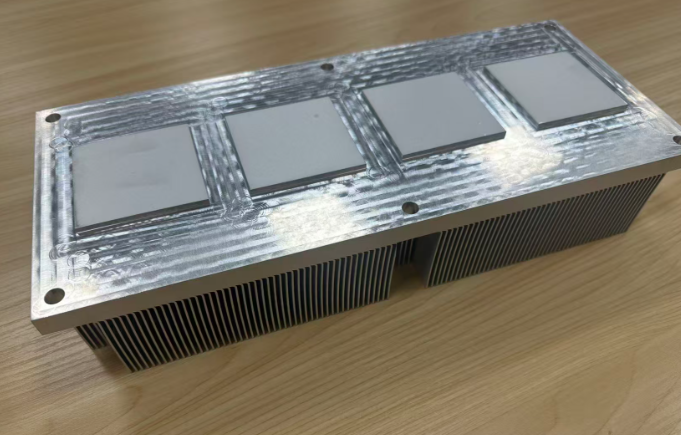

A biochemical analyzer of a medical equipment manufacturer needs to be equipped with 4 sets of TEC modules, each with a rated power of 50W, resulting in a total heat dissipation requirement of 200W. During the operation of the instrument, the temperature of the test paper reaction area needs to be controlled at 15℃ (10~15℃ lower than the ambient temperature) with a temperature control precision of ±1℃. Based on the design scheme of this paper, a hot-side heat sink was customized for this equipment.

3.2 Heat Sink Parameters and Processes

1.Hot-Side Heat Sink: Processed using the skived fin process, with dimensions of 200mm (length) × 150mm (width) × 80mm (height). The fin height is 80mm, the fin spacing is 2mm, and the base plate thickness is 10mm. The material is 6063 aluminum alloy (thermal conductivity: 201W/(m·K)), and the surface is treated with anodization to improve corrosion resistance.

2.Cold-Side Heat Sink: Processed using the profile extrusion process, with dimensions matching the hot-side base plate (200mm × 150mm) and a thickness of 15mm. The surface roughness is Ra = 0.6μm to ensure no obvious uneven points.

3.Cold-Hot Isolation: A 12mm gap is reserved between the cold side and the hot side, filled with high-temperature resistant foam material (thermal conductivity ≤ 0.03W/(m·K)).

3.3 Heat Dissipation Effect Verification

Under the test conditions of an ambient temperature of 25℃ and a relative humidity of 60%, after 4 sets of 50W TEC modules operated at full load for 2 hours, monitoring was conducted using thermocouples and infrared thermal imagers:

•The temperature of the TEC hot end was stably maintained at 55℃~58℃, which is lower than the rated maximum operating temperature of the TEC (80℃), meeting the safe operation requirements.

•The surface temperature of the cold-side heat sink was stably maintained at 14.8℃~15.2℃, with a temperature control precision of ±0.2℃, and no condensation or icing occurred on the surface.

•Through forced air cooling (air velocity: 2m/s) for the hot-side heat sink, the temperature difference between the maximum surface temperature and the ambient temperature was controlled within 35℃, and the heat dissipation efficiency met the design expectations.

4. Conclusions and Prospects

Aiming at the dual requirements of “condensation prevention” and “high-efficiency heat dissipation” for TEC heat sinks in medical precision instruments, this paper proposes a split-type design scheme. Through the profile extrusion process for the cold side, the skived fin process for the hot side, and the cold-hot isolation structure, the design pain points of traditional heat sinks are effectively solved. Case verification shows that the 200×150×80mm skived fin heat sink can stably support the heat dissipation requirements of 4 sets of 50W TEC modules, with a temperature control precision of ±0.2℃, meeting the strict requirements of medical analyzers.

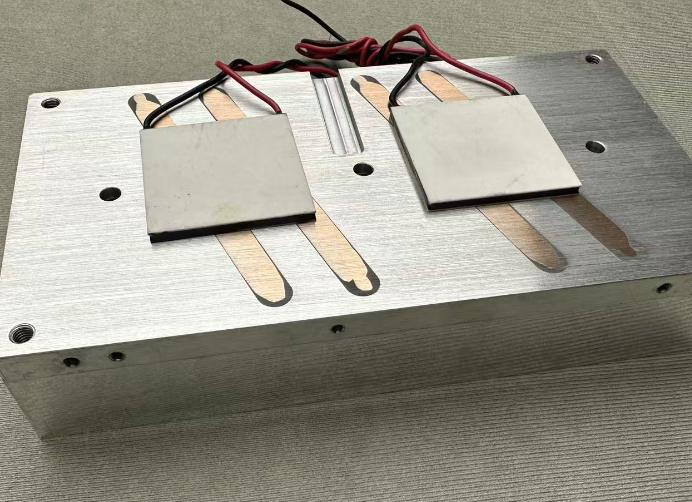

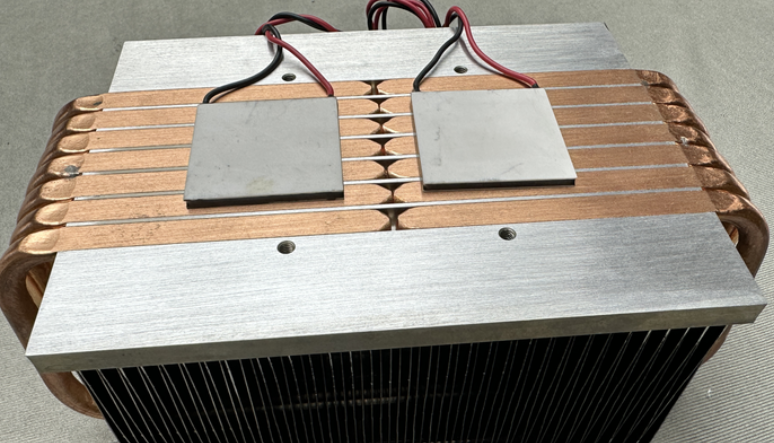

In order to improve the efficient heat dissipation of the hot surface, we can also adopt the heat pipe scheme. By utilizing the efficient heat transfer effect of the heat pipe, a large amount of heat can be instantly carried away to the fin, and then forced convection can be used to transfer the heat to the air, reducing the temperature of the TEC

In the future, further optimization can be made in the material selection of heat sinks (such as using copper alloys with higher thermal conductivity) and structural design (such as combining microchannel heat dissipation technology). Additionally, the exploration of hybrid modes of passive heat dissipation and active heat dissipation can be conducted to adapt to higher-power TEC modules and more extreme temperature control scenarios, providing more efficient heat dissipation solutions for the performance upgrade of medical precision instruments.