Coolant Selection and Material Compatibility: A Guide from Fluid Characteristics to Industry Practices.In industrial heat dissipation, electronic cooling, or precision equipment temperature control scenarios, the selection of coolants directly determines system stability and service life. Among the key decision-making factors, fluid-material compatibility and corrosion control are the core dimensions. This article starts from the characteristics of mainstream coolants, breaks down material adaptation logic, corrosion causes and solutions, and provides selection references combined with industry cases.Only by choosing the appropriate coolant and matching it with the liquid cooling plate can a stable and reliable thermal management system be achieved.

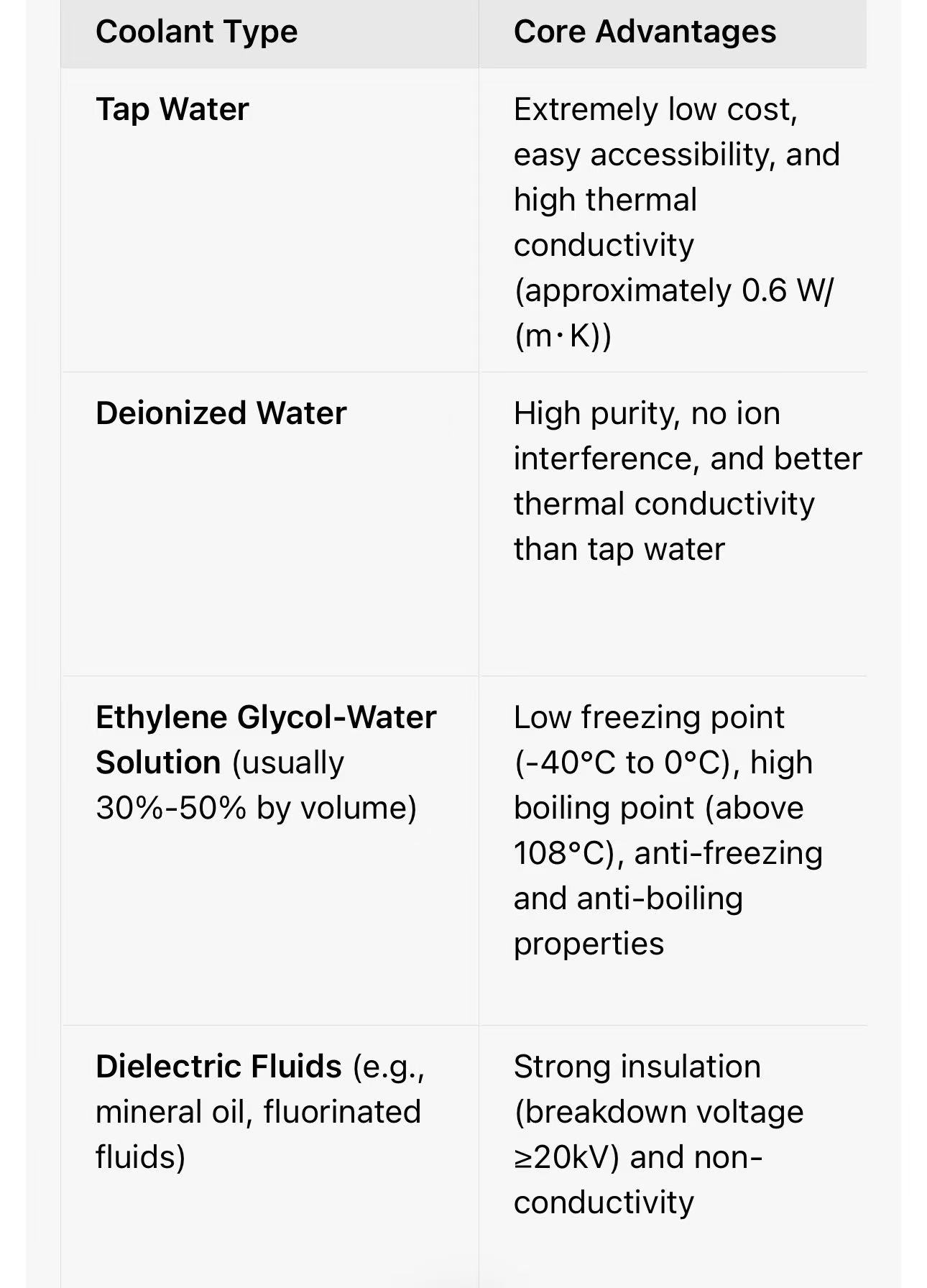

Types of Mainstream Coolants and Their Core Characteristics

Differences in coolant composition determine their applicable scenarios, thermal conductivity efficiency, and corrosion risks, which is the first step in selection.

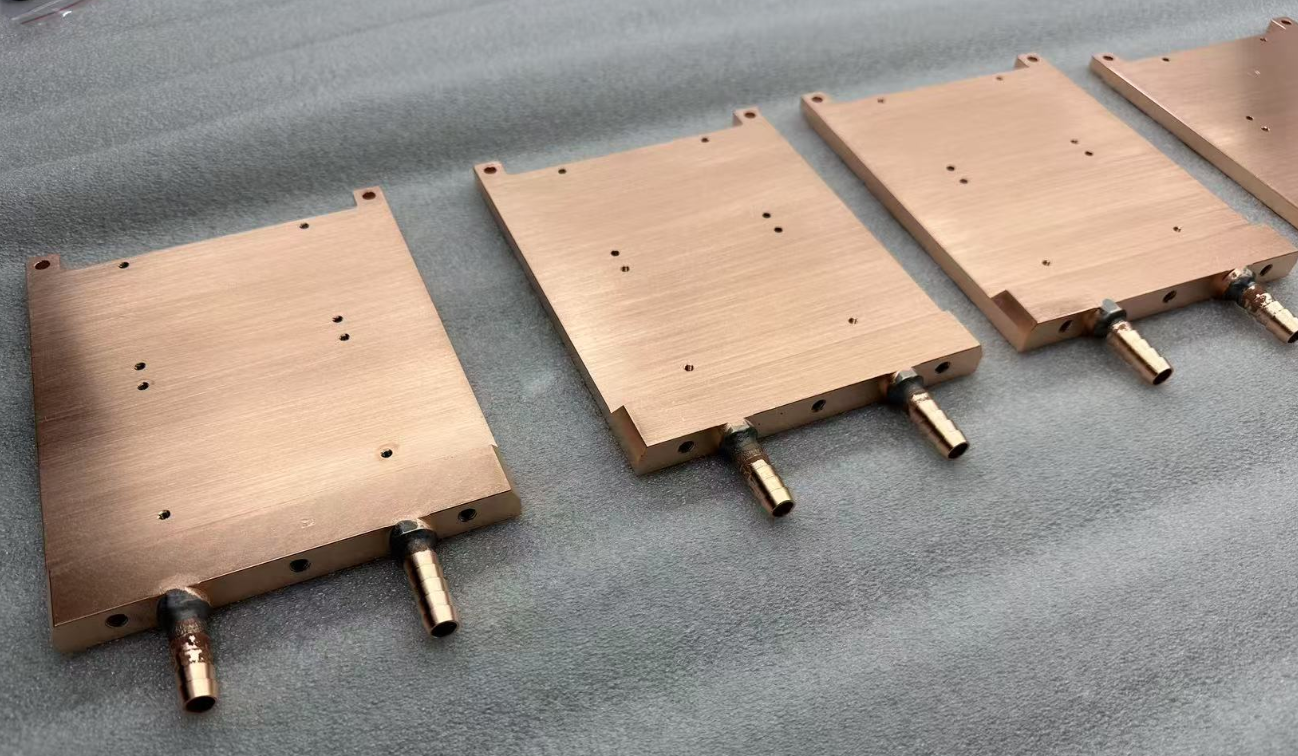

Key Material Compatibility: Adaptation Logic Centered on “Copper”

Copper is the most commonly used material for cooling channels (due to good thermal conductivity and moderate cost). Its compatibility with different coolants directly affects system service life, so special attention must be paid to the risk of chemical reactions.Chloride, calcium, and magnesium ions in tap water are the core causes of corrosion:Calcium and magnesium ions: Combine with sulfates and carbonates in water to form calcium carbonate and calcium sulfate scales. These scales adhere to the inner walls of cooling channels, reducing thermal conductivity efficiency (the thermal conductivity of scale is only 0.1-0.3 W/(m·K)) and even clogging channels in severe cases.Chloride ions: Penetrate the oxide protective film on the copper surface, causing “pitting corrosion”—small holes appear on the channel surface, gradually expanding and leading to leakage.

Solutions: If tap water must be used, two-step control is required:

1. Pretreatment: Remove some calcium and magnesium ions through filters to reduce the basis for scaling;

2. Add corrosion inhibitors: Incorporate phosphates (e.g., sodium phosphate) or organic acids (e.g., benzotriazole, BTA). The former forms a passivation film to isolate ions, while the latter adjusts the pH value to 7-9 (a neutral to slightly alkaline environment inhibits copper corrosion).

Copper and Deionized Water: Avoid the Hidden Risk of “Dezincification Corrosion”

Although deionized water removes impurity ions, its high-purity nature disrupts the chemical balance of copper—zinc in copper alloys is preferentially dissolved, causing “dezincification corrosion”. The channel surface becomes porous and loose, with a sharp drop in mechanical strength. Even without obvious rust, sudden cracking may occur. Medical industry (e.g., CT equipment cooling): Add 0.1%-0.5% benzotriazole (BTA) to deionized water to form a monomolecular protective film and prevent zinc dissolution; Precision laboratory instruments: Use “copper-nickel alloy” channels instead of pure copper. Nickel can enhance resistance to dezincification while maintaining thermal conductivity.

Copper and Ethylene Glycol-Water Solution: Compatibility Determined by Mixing Ratio

Pure ethylene glycol (100% concentration) is highly corrosive to copper, but when mixed with water, it forms a stable system with significantly improved compatibility. The key lies in controlling the mixing ratio:

• Recommended ratio: 30%-50% ethylene glycol + 50%-70% water. This ratio not only retains anti-freezing (-15°C to -40°C) and anti-boiling capabilities but also reduces the corrosion of ethylene glycol on copper (water molecules can buffer the chemical activity of ethylene glycol);

• Taboo: Avoid concentrations below 20% (insufficient anti-freezing performance; easy to freeze and crack channels at low temperatures) or above 60% (decreased thermal conductivity, and excessively high ethylene glycol concentration increases corrosion risk instead).

In addition, commercially available “automotive antifreeze” is essentially an ethylene glycol-water solution with pre-added corrosion inhibitors (e.g., borates, nitrites), which can be directly used in industrial copper channels. However, note that different brands should not be mixed (corrosion inhibitor components may conflict, causing precipitation).

Copper and Dielectric Fluids: Optimal Compatibility, but Attention to “Swelling”

Dielectric fluids (e.g., mineral oil) do not chemically react with copper, so compatibility is almost risk-free. However, non-corrosive issues must be noted: Some mineral oils can cause swelling of rubber seals (e.g., O-rings), which may lead to seal failure after long-term use; Solution: Select “synthetic dielectric fluids” (e.g., polyalphaolefins, PAO) or use fluororubber seals to avoid swelling.

Coolant Selection Decision Tree: 3 Steps to Determine the Optimal Solution

• Consider scenario requirements: It is generally used in the thermal management scheme of the liquid cooling plates of battery packs. Choose dielectric fluids for insulation needs, ethylene glycol-water solutions for low-temperature environments, deionized water for precision/medical scenarios, and tap water for temporary low-cost scenarios;

• Check material adaptation: For copper channels, add corrosion inhibitors to tap water, prevent dezincification in deionized water, and control the mixing ratio of ethylene glycol;Especially for the server liquid cooling plate modules in large-scale data center cloud computing systems

• Calculate long-term costs: Especially in the laser industry, in many cases, tap water is directly used as the coolant for the heat management circulation.Although tap water is cheap, the maintenance cost due to scaling is high; deionized water with corrosion inhibitors requires higher initial investment but can extend the system service life by 3-5 times.

Clarification of Common Misconceptions

• Misconception 1: The higher the purity of deionized water, the better. Excessive purification increases the risk of “dezincification corrosion”. For industrial use, the resistivity of deionized water should be controlled at 10-18 MΩ·cm; ultra-pure water is not necessary.

• Misconception 2: The more ethylene glycol added, the better the anti-freezing effect. When the concentration exceeds 60%, the freezing point rises instead (e.g., the freezing point of 70% ethylene glycol is approximately -45°C, while that of 80% ethylene glycol rises to -20°C).

• Misconception 3: The more corrosion inhibitors added, the better. Excessive corrosion inhibitors can form precipitates and clog channels; the addition amount should be 0.1%-1% of the coolant volume.

Therefore, any choice of coolant must be carefully considered, so as not to cause direct damage to the liquid cooling system of aluminum or copper products. We at KENFA TECH are professional thermal management experts and can provide system-level thermal management consultation and solution offerings to our clients. email to us :king@kenfatech.com