Application of Thermoelectric Cooling Chips in Dehumidifiers.Design and Dehumidification Application of TEC Semiconductor Cooling Chip Based on Acetone Heat Pipe and Skived Fin Heat Sink,In places such as libraries and museums, the preservation of high-precision cultural relics and equipment imposes stringent requirements on environmental humidity control. Traditional compressor-based dehumidification equipment suffers from drawbacks including high power consumption, large volume, and significant noise. To address these issues, this paper designs a high-efficiency cooling chip centered on TEC semiconductors, integrated with acetone low-temperature heat pipes and skived fin heat sinks. By leveraging phase-change heat transfer, it achieves low-power-consumption and noise-free deep dehumidification, catering to the special needs of cultural and museum venues.

1. Core Design Scheme and Structural Parameters

The design of this cooling chip follows the core logic of “high-efficiency heat dissipation – deep refrigeration – rapid dehumidification”. The parameters and connection methods of each component are as follows:

1. Selection and Installation of Skived Fin Heat Sink

A skived fin heat sink with a width of 80mm, length of 120mm, and height of 40mm is selected and mounted on the heating end of the TEC semiconductor. The skived fin structure features an ultra-large heat dissipation surface area, enabling rapid dissipation of heat generated during TEC operation. A fan with a size of 80mm is matched above the heat sink, enhancing the heat transfer efficiency to the air through forced convection, thus providing stable heat dissipation support for the continuous refrigeration of the TEC.

2. Innovative Application of Acetone Low-Temperature Heat Pipe

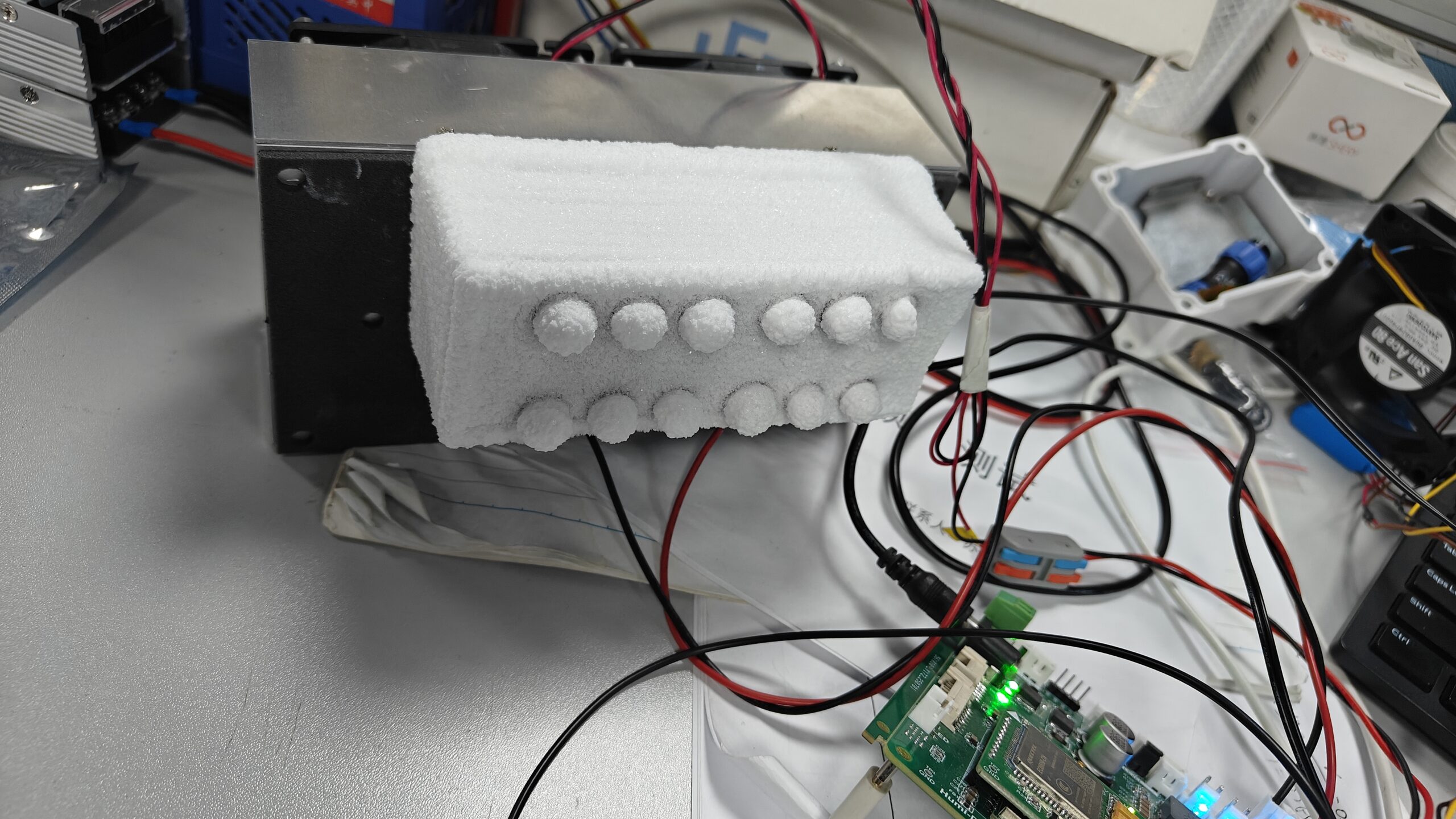

Heat pipes are high-efficiency heat-conducting components based on phase-change heat transfer. Breaking through the limitations of traditional heat pipe working media, this design adopts acetone as the internal working fluid of the heat pipe. Acetone boasts a unique advantage of low-temperature phase-change characteristics—it can evaporate and boil even at 0℃, which is highly compatible with the operating temperature of the TEC refrigeration end. The connection between the heat pipe and the TEC refrigeration end adopts the solder paste welding process, which ensures high heat conduction efficiency between them while providing excellent sealing performance and structural stability.

3. Construction of the Overall Working Link

Upon power-on, the TEC semiconductor rapidly forms a temperature difference between its “heating end” and “refrigeration end”. Heat from the heating end is quickly dissipated through the skived fin heat sink and the fan. The low temperature of the refrigeration end is transferred to the heat pipe via solder paste welding, triggering the phase-change reaction of acetone inside the pipe. Liquid acetone absorbs heat from the refrigeration end and evaporates into gas, and the gaseous acetone releases cold energy and liquefies again during its flow along the inner wall of the heat pipe. This cycle repeats, converting the point refrigeration of the TEC into surface refrigeration of the heat pipe, thus significantly expanding the refrigeration area.

2. Working Principle and Dehumidification Mechanism

The refrigeration and dehumidification process of this cooling chip is realized by the synergy of the TEC thermoelectric effect and heat pipe phase-change heat transfer. The specific mechanisms are as follows:

1. Synergy of Thermoelectric Refrigeration and Phase-Change Heat Transfer

Based on the Peltier effect, when the TEC semiconductor is powered on, carriers transfer energy as they move between the two ends, causing one end to continuously absorb heat for refrigeration and the other end to continuously release heat and heat up. The heat generated by the heating end is quickly discharged by the skived fin heat sink and the fan, preventing the TEC from malfunctioning due to overheating. The low temperature of the refrigeration end is transferred to the heat pipe through solder paste welding, triggering the phase-change reaction of acetone in the pipe—liquid acetone absorbs heat from the refrigeration end and evaporates into gas, and gaseous acetone releases cold energy and re-liquefies during its flow along the inner wall of the heat pipe. This cycle repeats, converting the point refrigeration of the TEC into the surface refrigeration of the heat pipe, and greatly expanding the refrigeration area.

2. Deep Dehumidification Based on the Principle of Ice Formation

When the surface temperature of the heat pipe drops to 0℃ or below, water vapor in the surrounding air will condense into frost or ice on the surface of the heat pipe. This process can efficiently capture free water molecules in the air, achieving deep dehumidification. Compared with traditional compressor dehumidification equipment, this design does not require a complex refrigerant circulation system and achieves dehumidification through physical phase change, featuring low power consumption, low noise, and stable operation, which is perfectly suitable for libraries, museums and other places sensitive to environmental quietness and equipment power consumption.

3. Application Advantages and Scenario Value

1. Low Power Consumption and Quiet Operation

Abandoning the high-power operation mode of traditional compressors, this cooling chip is centered on TEC semiconductors, with the auxiliary functions of fans and heat pipes, significantly reducing the overall power consumption. Meanwhile, there is no mechanical vibration and noise caused by compressors, which can ensure a quiet environment in cultural and museum venues.

2. Deep Dehumidification Meets the Requirements of Precision Preservation

Based on the dehumidification principle of ice formation, the ambient humidity can be controlled at a lower level, meeting the stringent requirements for low-humidity preservation of ancient books, calligraphy and paintings, precision instruments, etc., and effectively preventing mildew of cultural relics and damage of equipment due to moisture.

3. Compact Structure and Easy Integration

Each component has regular dimensions and the overall structure is compact, which can be flexibly integrated into small dehumidification equipment, facilitating installation and use in narrow spaces such as library bookshelves and museum display cabinets.

4. Conclusion and Outlook

This design maximizes the refrigeration efficiency of TEC semiconductors through the innovative combination of acetone low-temperature heat pipes and skived fin heat sinks, achieving low-power-consumption and noise-free deep dehumidification. This cooling chip can not only meet the preservation needs of high-precision equipment and cultural relics in libraries and museums, but also be extended to scenarios with strict humidity control requirements such as laboratories and archives. In the future, by optimizing the heat pipe structure and improving TEC energy efficiency, it is possible to further reduce energy consumption, expand the refrigeration area, and promote the large-scale application of compressor-free dehumidification technology.Certainly, we can also enhance the efficiency of the TEC by cooling its hot side with a liquid cold plate. This will further lower the temperature of the cold side. We are ready to provide customized design of such TEC modules for customers based on any specific requirements.