Thermal Design for CPO Microring Modulators

1. The Evolution of CPO and the Thermal Bottleneck of Microring Modulators The explosive growth of AI computing clusters and the evolution of data center interconnection rates to 100Gbps/lane and above have driven the transformation of Co-Packaged Optics (CPO) technology from concept to large-scale deployment. Its core value lies in breaking the traditional discrete architecture […]

Thermal Management in Communication Base Stations

Driven by the wave of digitalization, the popularization of 5G communication networks is accelerating, and the research and development of 6G technology is advancing continuously. As the core hub of information transmission, communication base stations have witnessed a significant increase in deployment density and operational load. The continuous improvement in the integration of base station […]

What is a Mechanically Pumped Two-Phase Loop (MPTL)?

In fields such as aerospace thermal control, high-performance computing, and new energy, efficient heat transfer and precise temperature control have always been core technical requirements. Traditional single-phase fluid cooling systems are limited by the bottleneck of sensible heat transfer and are difficult to meet the heat dissipation needs of high-power density equipment. As an efficient […]

Copper-Aluminum Explosion-Welded Heat Sink

Copper-Aluminum Bonding via Explosive Welding heat sink : Principles, Production Processes, Applications and Key Considerations In fields such as electronic thermal management, IGBT ,new energy power systems, and rail transit, copper-aluminum composite materials have emerged as ideal alternatives to pure copper components, leveraging copper’s excellent electrical and thermal conductivity alongside aluminum’s advantages of light weight […]

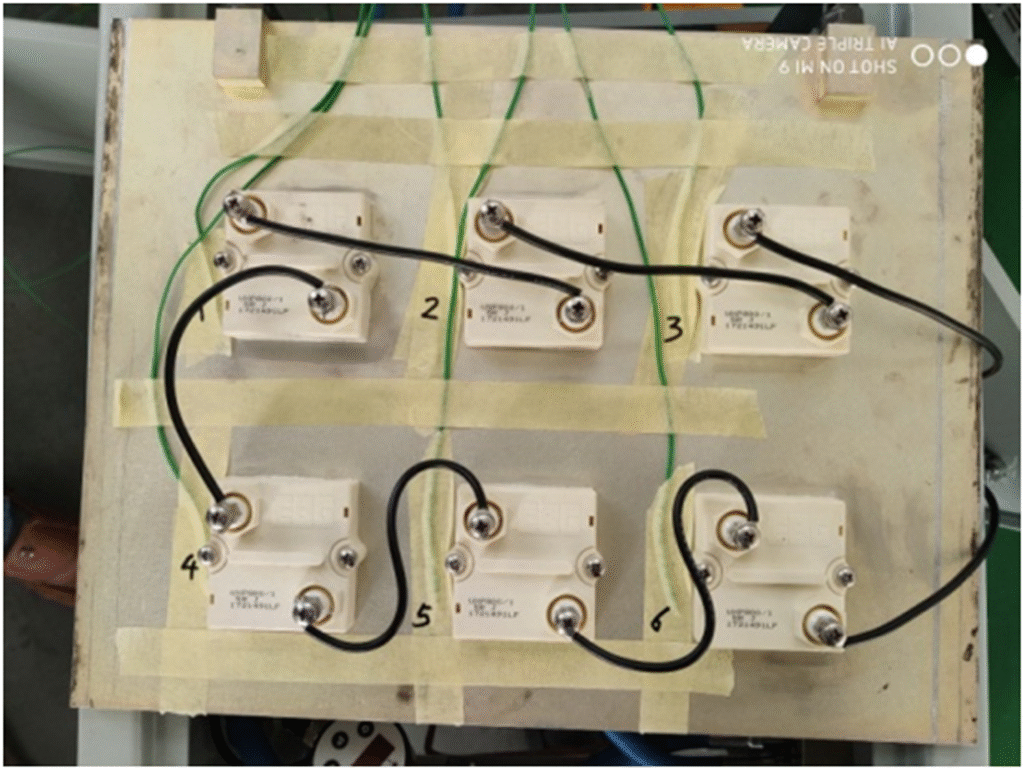

340Ah/104-Series Battery cells liquid cold plate

Design and Verification of a Liquid Cooling Plate Heat Dissipation Solution for 340Ah/104-Series Battery Modules Driven by the “dual carbon” goals, the energy storage industry is ushering in a golden era of large-scale development. Lithium-ion batteries, as the core components of energy storage systems, have their thermal management capabilities directly determining the system’s safety, cycle […]

Application of Thermoelectric Cooling Chips in Dehumidifiers

Application of Thermoelectric Cooling Chips in Dehumidifiers.Design and Dehumidification Application of TEC Semiconductor Cooling Chip Based on Acetone Heat Pipe and Skived Fin Heat Sink,In places such as libraries and museums, the preservation of high-precision cultural relics and equipment imposes stringent requirements on environmental humidity control. Traditional compressor-based dehumidification equipment suffers from drawbacks including high […]

A Production Process of Turbulence-Enhanced Bent Channel Tubed Liquid Cold Plate

This invention introduces a turbulence-enhanced bent channel liquid cold plate using a 6061-T5 aluminum substrate with embedded red copper tubes forming M-shaped flows. Key features include 30° “horizontal-downward-lifting” bends in straight sections to generate turbulence, improving convective heat transfer by over 10% while limiting flow resistance rise to under 10%. Simulations confirm reduced chip temperatures and enhanced efficiency compared to traditional straight-pipe designs, making it suitable for high-power electronics and batteries without added internals.

How to design AI Chip Test Fixtures

Core Equipment for Reliability Verification: Technological Breakthroughs and Application Value of Liquid Cooled Plates Dedicated to AI Chip Test Fixtures In the full process of AI chips from packaging to mass production, reliability verification is a key link that determines product yield and market competitiveness. With the thermal design power (TDP) of high-performance chips such […]

Thermal Management of High-Speed Motors

Thermal Management of High-Speed Motors: Requirements and Practice of Shell Liquid Cooling Heat Dissipation Solutions The popularity of high-speed motors (typically defined as motors with a rotational speed ≥ 10000r/min) in industrial drives, new energy vehicles, aerospace, and other fields has made thermal management capability a core bottleneck restricting performance and lifespan. When a motor […]