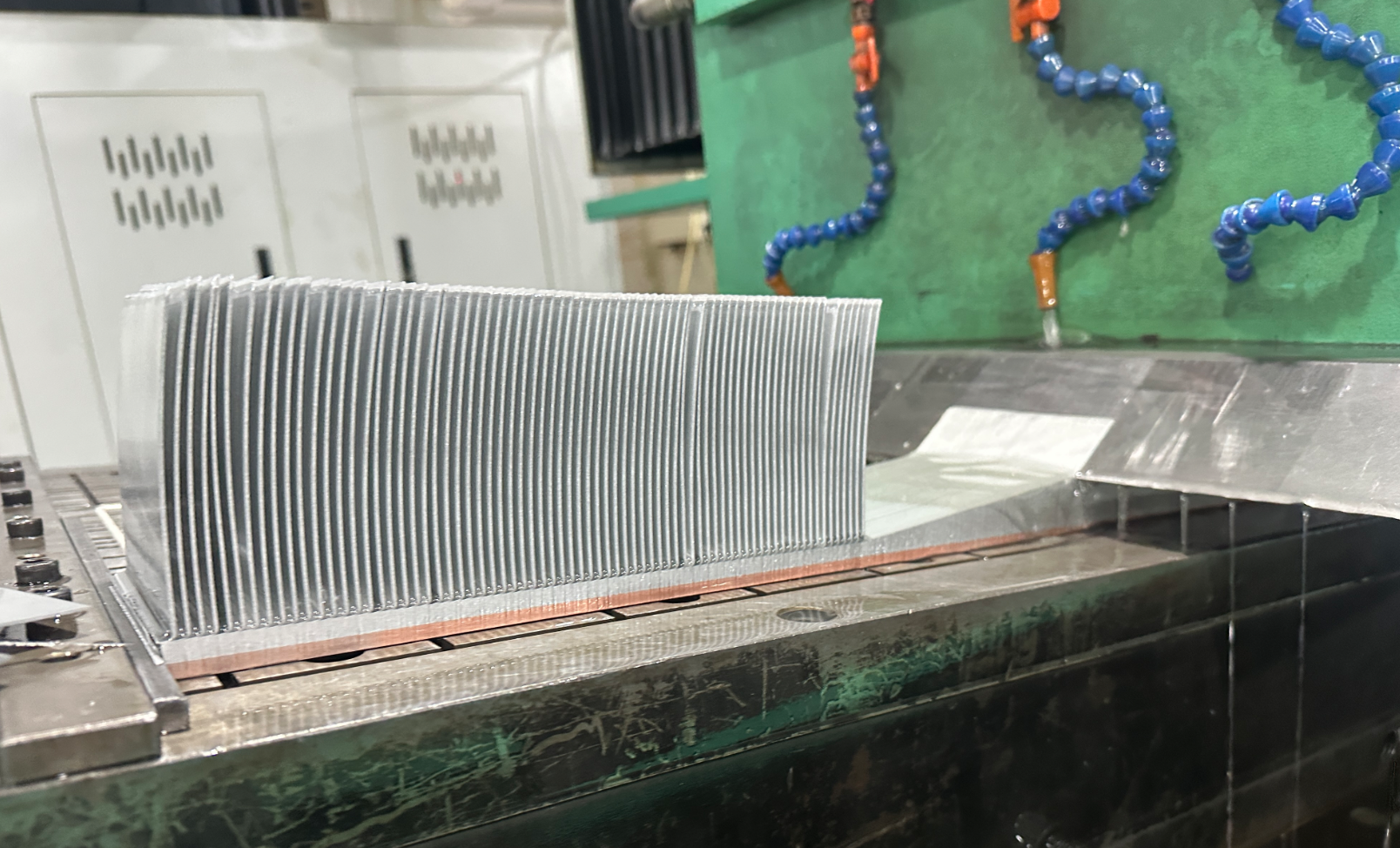

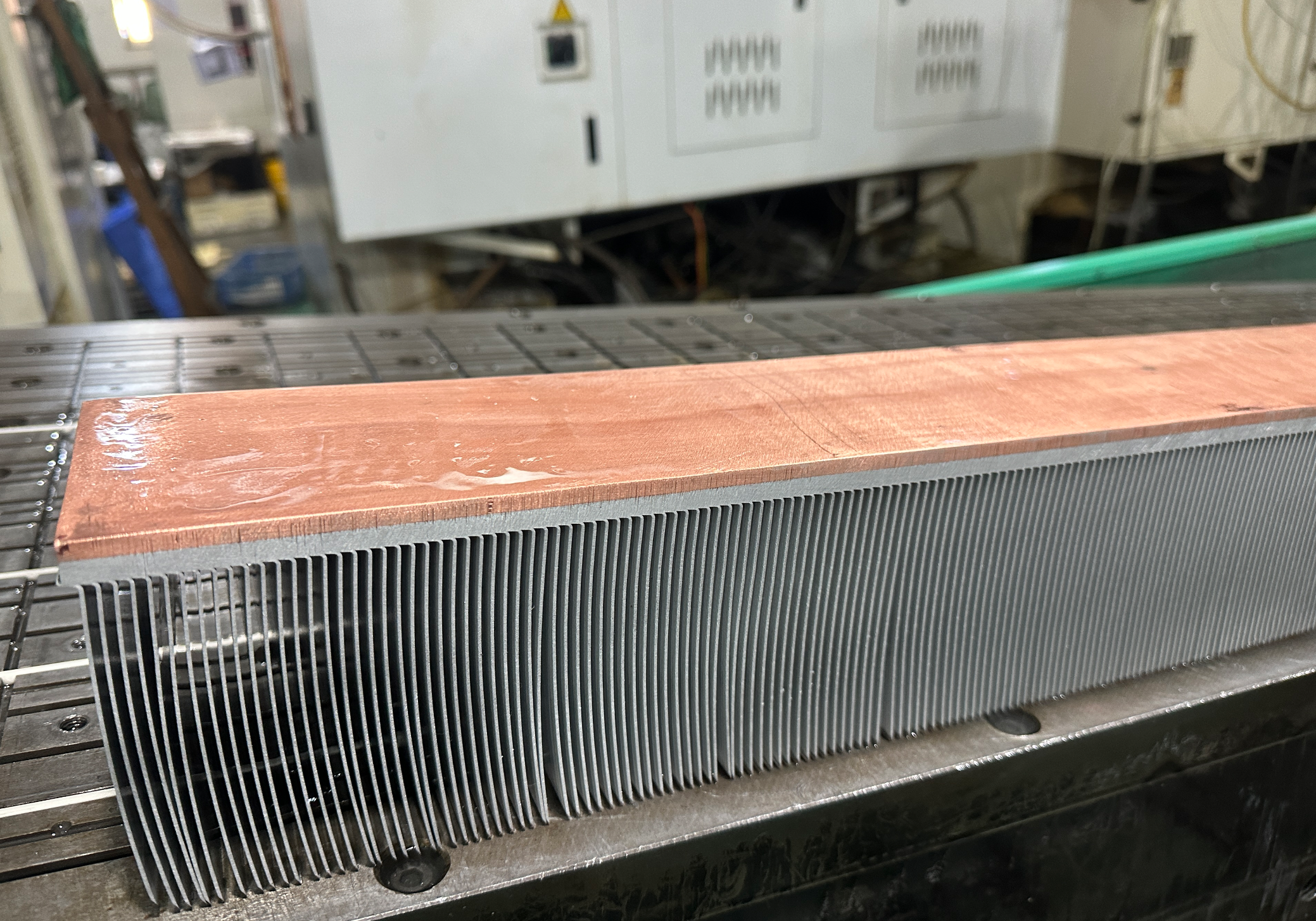

Copper-Aluminum Bonding via Explosive Welding heat sink : Principles, Production Processes, Applications and Key Considerations

In fields such as electronic thermal management, IGBT ,new energy power systems, and rail transit, copper-aluminum composite materials have emerged as ideal alternatives to pure copper components, leveraging copper’s excellent electrical and thermal conductivity alongside aluminum’s advantages of light weight and low cost. As a solid-state welding technology, explosive welding enables high-strength metallurgical bonding between dissimilar copper and aluminum metals, yielding finished products with performance far superior to those manufactured via traditional processes like brazing and mechanical joining. This article comprehensively analyzes copper-aluminum explosive welding technology from the perspectives of fundamental principles, production procedures, troubleshooting, application scenarios, as well as advantages and limitations.skived fin heat sink.

1. Core Principles of Copper-Aluminum Explosive Welding

The essence of copper-aluminum explosive welding lies in utilizing the instantaneous energy generated by explosive detonation to achieve metallurgical bonding between dissimilar metals. Classified as a form of cold welding, the process involves no significant melting of the metals throughout.

When the explosive is detonated, the detonation wave propagates along the surface of the metal plates at a velocity of 2,000–5,000 m/s, exerting intense instantaneous impact force on the aluminum plate (referred to as the flyer plate) attached closely to the explosive. Under high pressure, the flyer plate collides with the fixed copper plate (referred to as the base plate) at a speed of several hundred meters per second. The high pressure and plastic deformation induced upon impact completely crush and extrude the oxide films on the contact surfaces of the two metals, exposing the pure metal lattices. At this moment, interatomic diffusion and metallic bonding forces drive the formation of a unique wavy bonding structure at the copper-aluminum interface. This wavy interface significantly enhances mechanical interlocking and bonding strength, ensuring the composite material possesses excellent mechanical properties, electrical conductivity and thermal conductivity.

It is crucial to strictly control the energy input during copper-aluminum explosive welding: insufficient energy fails to form an effective wavy interface, resulting in low bonding rates; excessive energy, on the other hand, raises the local temperature at the interface beyond the copper-aluminum eutectic temperature, leading to the formation of brittle and hard intermetallic compounds which ultimately degrade bonding performance.

2. Complete Production Process of Copper-Aluminum Explosive Welding

The production of copper-aluminum explosive welding involves precise pre-preparation, rigorous on-site construction and necessary post-processing, following the specific steps outlined below:

2.1 Base Material Preprocessing

• Material Selection: For the aluminum plate, grades with good plasticity such as 1060 and 3003 are preferred, while T2 electrolytic copper is selected for the copper plate to ensure optimal plasticity matching between the two metals. The thickness of the plates is determined based on product requirements; a common thickness combination for electronic heat dissipation components is 1–5 mm aluminum plate paired with 2–20 mm copper plate.

• Surface Cleaning: Sanding or sandblasting is employed to remove surface oxide layers, oil stains and impurities. Subsequent cleaning with acetone or anhydrous ethanol is performed, followed by immediate assembly after drying to prevent secondary oxidation.

• Flatness Correction: Deformed plates are flattened to ensure uniform assembly gaps in subsequent steps.

2.2 Assembly and Explosive Charge Design

• Gap Adjustment: The flyer plate and base plate are placed in parallel with a specific gap (known as the flyer plate gap). A gap that is too small leads to excessive energy, whereas an overly large gap causes substantial energy loss.

• Explosive Laying: Low-detonation-velocity explosives with stable detonation rates (e.g., ammonium nitrate fuel oil explosives) are selected. The areal density is calculated according to plate thickness, generally controlled within the range of 50–300 g/m². The explosive must be laid evenly, with a 5–10 cm blank zone reserved at the edges to avoid edge stress concentration.

• Initiator Installation: An initiator is mounted at one end of the explosive charge to ensure the detonation wave propagates parallel to the plate surface.

2.3 On-site Detonation Welding

• Safety Protection: A spacious, dedicated blasting site is selected, a restricted area is established, and professional protective equipment is provided.

• Detonation Operation: The explosive is detonated remotely, and the propagation state of the detonation wave is observed to ensure stable collision between the flyer plate and the base plate.

• Preliminary Inspection: After detonation, residual explosives and debris are removed, and a visual inspection is conducted to check for obvious defects such as deformation and cracking on the plate surface.

2.4 Post-treatment Processes

• Annealing Treatment: The welded composite plate is placed in an annealing furnace and held at 150–250 °C for 1–2 hours to eliminate welding residual stress and improve interface fatigue resistance. The temperature must never exceed 300 °C to prevent the formation of intermetallic compounds.

• Precision Machining: Cutting, milling, drilling and other machining operations are performed according to product requirements to fabricate structures such as flow channels and mounting holes. Surface grinding and polishing are carried out to enhance appearance and heat dissipation efficiency.

• Quality Inspection: Ultrasonic testing (UT) is conducted to check the interface bonding rate, which is required to be ≥ 98%. Tensile testing is performed to measure bonding strength, with the acceptance criterion that the fracture occurs in the aluminum plate rather than at the bonding interface. Hydrostatic testing is carried out on components with sealing requirements to ensure no leakage.

3. Common Problems in Production and Corresponding Solutions

The production of copper-aluminum explosive welding is influenced by various factors such as process parameters and environmental conditions, and is prone to the following defects, which require targeted solutions:

Defect Type Core Causes Solutions

Interface Unbonding Unreasonable flyer plate gap, insufficient explosive charge, inadequate surface cleaning Adjust the gap to 2–4 mm and appropriately increase the explosive areal density; re-grind and clean the contact surfaces before welding

Interface Porosity Residual oil/water on the surface, unstable detonation velocity Strictly control surface cleanliness and dryness; select explosives with stable detonation velocity and optimize charging methods

Wavy Interface Distortion Excessively high detonation velocity, insufficient base plate support stiffness Reduce the explosive detonation velocity to the range of 3,000–4,000 m/s; fix the base plate with rigid fixtures and add backing plates to enhance stability

Excessive Intermetallic Compounds Excessive detonation energy, excessively high annealing temperature Reduce the explosive charge to control impact velocity; strictly limit the annealing temperature to below 250 °C

Plate Warping and Deformation Excessively thin base plate, uneven detonation wave propagation Increase the base plate thickness or use temporary backing plates; optimize the uniformity of explosive laying to ensure parallel detonation wave propagation

4. Application Fields of Copper-Aluminum Explosive Welding

Benefiting from its advantages of high strength, low interfacial thermal resistance and light weight, copper-aluminum explosive welding composite materials are widely applied across multiple industrial sectors:

4.1 Electronic Thermal Management Field

This represents one of the core application scenarios for copper-aluminum explosive welding. Copper-aluminum composite plates manufactured via explosive welding can be used to produce high-power IGBT heat dissipation substrates, server heat sinks, new energy vehicle battery cooling plates and other components. Their extremely low interfacial thermal resistance (10^{-6} \sim 10^{-5}\ \text{m}^2\cdot\text{K/W}) enables rapid heat conduction, while the lightweight characteristic reduces the overall weight of the equipment, aligning with the miniaturization and high-efficiency development trends of electronic devices.

4.2 Power Engineering Field

It is used to fabricate high-voltage busbars, cable transition joints and other components. Copper-aluminum composite busbars combine copper’s high electrical conductivity with aluminum’s cost-effectiveness, reducing costs by more than 30% compared to pure copper busbars while offering easy installation, and are thus widely used in power substations, distribution cabinets and other electrical equipment.

4.3 Rail Transit and Aerospace Fields

It is employed in manufacturing pantograph sliding plates for trains, heat dissipation components for aero-engines and other parts. This field imposes stringent requirements on material strength, fatigue resistance and lightweight properties, and copper-aluminum explosive welding composite materials can meet these rigorous working conditions while reducing equipment weight.

4.4 Chemical Engineering Field

It is used to produce corrosion-resistant heat exchangers, reactor liners and other equipment. Copper-aluminum composite plates exhibit better corrosion resistance than pure copper and are more cost-effective than high-end materials such as titanium alloys, making them suitable for heat exchange applications involving weak acids and weak alkalis.

5. Advantages and Limitations of Copper-Aluminum Explosive Welding

5.1 Core Advantages

• High Bonding Strength: Metallurgical bonding is achieved, with tensile strength reaching that of the aluminum plate itself and peel strength ≥ 100 N/mm, far exceeding that of mechanical connections and brazing.

• Low Interfacial Thermal Resistance: The wavy metallurgical bonding interface ensures high heat transfer efficiency, with minimal impact on the performance of heat dissipation components.

• Retention of Original Metal Properties: The solid-state welding process involves no melting, so the electrical and thermal conductivity of copper and aluminum remain almost unaffected.

• Flexible Material Selection: It enables the compounding of copper and aluminum plates with different thicknesses and grades, meeting diverse product requirements.

• High Cost-effectiveness: Compared to pure copper components, it significantly reduces raw material costs, while the lightweight feature lowers transportation and installation costs.

5.2 Limitations

• High Process Threshold: Precise control of parameters such as explosive charge and gap is required, demanding high technical proficiency from operators. Specialized blasting sites are necessary, subject to strict safety regulations.

• Product Size Limitations: Restricted by the propagation distance of the detonation wave, it is challenging to produce ultra-large-area composite plates, with the typical area of a single plate not exceeding 10 m².

• Difficult Post-processing: Residual stress exists in the welded plates, requiring annealing treatment, which adds production procedures and costs.

• Unsuitability for Complex Structures: It is only applicable to the compounding of components with simple shapes such as flat plates and curved surfaces, and cannot be used for welding special-shaped parts.

6. Practical Considerations for Copper-Aluminum Explosive Welding

1. Safety First: Explosive welding involves the use of explosives and must strictly comply with national blasting safety regulations. Operations must be performed by professionals equipped with comprehensive safety protection measures.

2. Parameter Standardization: Develop corresponding parameter tables for explosive charge and gap based on different copper-aluminum thickness combinations to avoid empirical operations.

3. Quality Inspection Prioritization: Conduct ultrasonic testing immediately after welding to detect interface defects early and avoid waste caused by subsequent processing.

4. Storage and Transportation: Finished composite plates must be protected from moisture and collision to prevent surface oxidation and deformation. Secure fixation during transportation is required to avoid interface cracking due to jolting.

Conclusion

Copper-aluminum explosive welding technology has broken the technical barriers to the efficient bonding of dissimilar metals, providing a new pathway for the application of lightweight, high-performance composite materials. With the rapid development of fields such as electronic thermal management and new energy, copper-aluminum explosive welding technology will continue to be optimized and upgraded, playing an increasingly important role in more high-end manufacturing sectors. For industry practitioners, mastering the principles and key process points of explosive welding is crucial to enhancing product competitiveness.

Based on years of research into thermal management for high-power chips, KENFA has applied this technology to the manufacturing of heat sinks. This solution effectively addresses heat dissipation challenges posed by high-power chips and those with high heat flux density, while simultaneously reducing both costs and product weight. So you can email to us :king@kenfatech.com ,Customize Your Exclusive Heat Sink.