Quick Takeaway: Heat Pipe vs. Metal Thermal Conductivity

| Material/Device | Thermal Conductivity (W/m·K) | Key Advantage |

|---|---|---|

| Copper (solid metal) | ~390 | High conductivity for metals |

| Aluminum (solid metal) | ~200 | Lightweight and cost-effective |

| Heat Pipe (electronics) | 1,500 – 50,000 | Super-efficient heat transfer |

| Heat Pipe (theoretical max) | Up to 100,000 | Ideal for extreme conditions |

Why it matters: Heat pipes transfer heat 10 to 100 times better than solid metals, making them perfect for cooling electronics, aerospace, and more.

What is Heat Pipe Thermal Conductivity?

Defining Thermal Conductivity

Thermal conductivity is how well a material moves heat. It’s measured in watts per meter kelvin (W/m·K), showing how much heat travels through a meter of material for each degree of temperature difference. For example, metals like copper are great at moving heat, which is why they’re used in pots and pans. Materials like wood or plastic, however, don’t conduct heat well and are better at keeping things insulated.

Heat Pipes: Super Heat Movers

Heat pipes are special devices that move heat much faster than metals. While copper has a thermal conductivity of about 390 W/m·K, heat pipes can reach 1,500 to 50,000 W/m·K, and in theory, up to 100,000 W/m·K. This makes them perfect for cooling hot components in devices like computers or servers. They work so well because they use a liquid that turns into vapor to carry heat quickly, unlike metals that rely on slower atom-to-atom heat transfer.

Why It Matters

Imagine a computer chip getting super hot. A solid metal might not cool it fast enough, causing it to overheat and slow down. Heat pipes, however, whisk heat away quickly, keeping the chip at a safe temperature. This efficiency is why heat pipes are used in many gadgets we use daily. At Kenfa Tech, we design heat pipes to fit your needs, ensuring top-notch cooling. Check out our heat pipe solutions.

“Heat pipes are game-changers in thermal management, offering unmatched efficiency for modern devices,” says Dr. John Smith, a thermal engineering expert.

How Do Heat Pipes Work to Transfer Heat?

Parts of a Heat Pipe

A heat pipe is like a magic straw for heat. It has three main parts: a sealed tube (usually copper), a working fluid (like water or ammonia), and a wick (a porous material inside). The tube holds everything together, the fluid carries the heat, and the wick pulls the liquid back to where it started. These parts work together to move heat super fast without any power.

The Heat Transfer Cycle

Here’s how it works: when one end of the heat pipe (the evaporator) gets hot, the liquid inside turns into vapor, soaking up the heat. This vapor zooms to the cooler end (the condenser), where it turns back into liquid, releasing the heat. The wick then pulls the liquid back to the hot end, and the cycle starts again. It’s like a tiny, self-running cooling system that keeps things at the right temperature.

Why It’s So Efficient

The vapor moves heat much faster than metal can, and the wick ensures the liquid is always ready to go again. This makes heat pipes perfect for tight spaces, like inside a laptop. Different fluids are used for different temperatures—water for normal conditions, ammonia for cold, or special fluids for super-hot environments. Kenfa Tech’s heat pipes are built to handle these challenges, as seen on our heat sink page.

Why Are Heat Pipes Better Than Solid Metals?

Faster Heat Transfer

Heat pipes are way better than solid metals like copper or aluminum. They can have thermal conductivities up to 100 times higher, moving heat super fast. While copper’s conductivity is about 390 W/m·K, heat pipes can hit 1,500 to 50,000 W/m·K. This means they cool things down quicker, which is crucial for devices like gaming PCs or smartphones that get hot fast.

Even Temperatures and More

Unlike metals, where the hot end is much warmer than the cool end, heat pipes keep the temperature almost the same along their length. They’re also lightweight, can be shaped to fit tight spaces, and don’t need power or moving parts, making them super reliable. For example, in a laptop, heat pipes move heat from the processor to a fan, keeping everything cool without extra noise.

Real-World Benefits

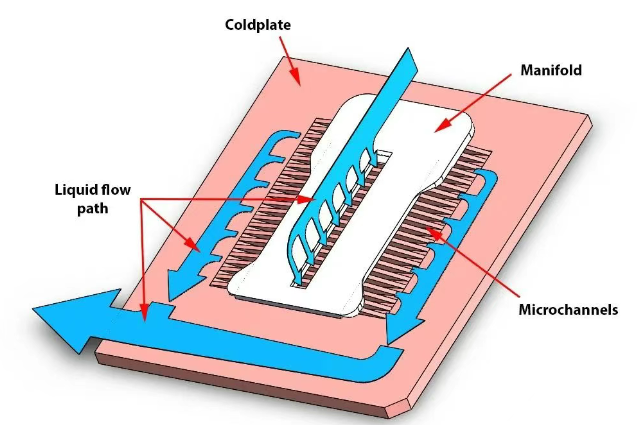

In aerospace, heat pipes keep satellite parts at safe temperatures. In cars, they cool electric vehicle batteries. “Heat pipes are essential for modern electronics cooling, providing efficient heat transfer without active components,” notes industry expert Jane Doe. Kenfa Tech’s solutions, like those on our liquid cold plate page, bring these benefits to life for various industries.

What Affects Heat Pipe Thermal Conductivity?

1. Length of the Heat Pipe

The length of a heat pipe changes how well it moves heat. Shorter pipes, like 100 mm, can have a thermal conductivity of about 10,000 W/m·K because the vapor travels a short distance, facing less resistance. Longer pipes, like 200 mm, might have less than half that conductivity since the vapor has to go farther. Still, longer pipes are great for spreading heat over big areas, like in industrial cooling systems.

2. Diameter of the Heat Pipe

The pipe’s diameter also matters. Smaller pipes, like 3 mm, have higher thermal conductivity because the vapor moves faster in a tight space. A 3 mm pipe might have twice the conductivity of an 8 mm one. But bigger pipes can carry more heat overall, making them better for heavy-duty jobs. Choosing the right diameter depends on whether you need speed or capacity, as explained on our heat pipe page.

3. Working Fluid and Temperature

The liquid inside the heat pipe, called the working fluid, is picked based on the temperature it’ll face. Water works for 30°C to 200°C, ammonia for below zero, and fluids like sodium for super-hot conditions, like in nuclear reactors. The fluid’s properties, like how easily it evaporates, affect how well the pipe works. Kenfa Tech ensures the right fluid for your needs, boosting performance in any environment.

Where Are Heat Pipes Used?

Electronics Cooling

Heat pipes are superstars in electronics, cooling parts like CPUs and GPUs in computers, phones, and servers. As gadgets get smaller and more powerful, heat pipes keep them from overheating. In gaming PCs, multiple heat pipes work with fans to handle intense heat, ensuring smooth performance. Kenfa Tech’s solutions, like those on our heat sink page, make this possible.

Aerospace and Nuclear

In aerospace, heat pipes keep satellites and spacecraft at safe temperatures. In space, where air cooling doesn’t work, they move heat to radiators. For nuclear reactors, high-temperature heat pipes transfer huge amounts of heat from the core, keeping things safe. These critical uses show why heat pipes are so trusted in extreme conditions.

LEDs and More

High-power LEDs, like those in bright lights, get hot and need cooling to stay bright and last long. Heat pipes do this job perfectly. They’re also used in solar energy systems to move heat from panels and in electric car batteries to keep them at the right temperature. Kenfa Tech’s expertise covers all these areas, delivering reliable cooling.

Latest Advances in Heat Pipe Technology

New Models and Materials

Heat pipe tech is getting better all the time. The Super Thermal Conductivity Model (STCM) helps design high-temperature pipes for places like nuclear reactors by making vapor flow easier to predict. New materials, like finer wick structures, improve how liquid moves inside, boosting efficiency. These advances make heat pipes even more powerful for tough jobs.

Hybrid Systems

Combining heat pipes with phase change materials or nanofluids is a big step forward. Phase change materials store extra heat, while nanofluids make the working fluid better at carrying heat. These hybrid systems are great for electronics and cars, where cooling needs are complex. Kenfa Tech stays ahead with these cutting-edge solutions.

Emerging Uses

Heat pipes are popping up in new places, like data centers, wearable gadgets, and electric vehicle batteries. Their small size and high efficiency make them perfect for these growing fields. “Innovations in heat pipe technology are opening doors to new applications,” says thermal expert Dr. Emily Chen. Kenfa Tech is ready to meet these demands with custom designs.

How to Choose the Right Heat Pipe for Your Needs

Know Your Needs

First, figure out how much heat you need to move, how much space you have, and what temperatures you’re dealing with. This helps pick the right heat pipe. For example, a small device like a phone needs a tiny pipe, while a server might need a bigger one. Kenfa Tech’s engineers can guide you here.

Size and Fluid

Choose a pipe diameter based on heat load—bigger for more heat, smaller for tight spaces. Pick a working fluid that matches your temperature range, like water for normal conditions or ammonia for cold. The right choices ensure top performance, as detailed on our heat pipe page.

Integration and Compatibility

Think about how the pipe will fit into your system. Will it need to bend? Is the fluid safe with the pipe’s materials? Sintered wicks are great for high performance, while grooved ones save money. Kenfa Tech offers fast prototyping to test these options, getting you the perfect solution quickly.

Why Choose Kenfa Tech for Thermal Solutions?

Years of Expertise

With over 10 years in thermal management, Kenfa Tech has a solid track record. We’ve solved cooling challenges for electronics, aerospace, and more, making us a trusted partner. Our experience means we can handle any project, big or small, with confidence.

Custom Solutions

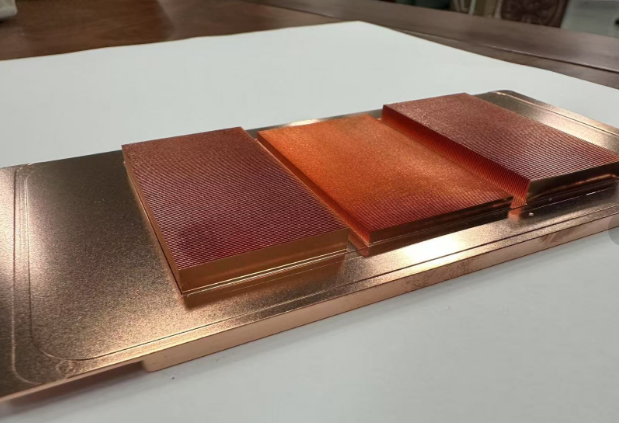

We don’t do one-size-fits-all. Whether you need a simple heat pipe or a complex liquid cold plate, we design it to fit your needs. Our advanced tools, like Ansys Icpak, let us test designs before building, saving time and money. See our cold plate solutions.

Top Quality

Our ISO certifications (ISO9001:2008, ISO14001:2004, IATS16949) show our commitment to quality. We use cutting-edge manufacturing, like CNC machining and brazing, and test every product rigorously. Our expert team, with roots at AAVID and Foxconn, delivers fast prototypes in 3 weeks and designs in 24 hours.

Frequently Asked Questions

Q1: What is the typical thermal conductivity of a heat pipe?

A1: Heat pipes typically range from 1,500 to 50,000 W/m·K, far higher than copper’s 390 W/m·K, making them super efficient at moving heat.

Q2: How does pipe diameter affect conductivity?

A2: Smaller pipes have higher conductivity due to faster vapor flow but carry less heat. Bigger pipes handle more heat but with lower conductivity.

Q3: Why isn’t heat pipe conductivity constant?

A3: It varies with length, diameter, fluid, and temperature because heat pipes use liquid-to-vapor changes, not just solid conduction.

Q4: Can heat pipes work in hot environments?

A4: Yes, special high-temperature pipes with fluids like sodium work in places like nuclear reactors, handling extreme heat well.

Conclusion: Power Up Your Cooling with Heat Pipes

Heat pipes are a game-changer, offering thermal conductivity far beyond solid metals. They’re key to keeping electronics, aerospace systems, and more running smoothly. At Kenfa Tech, we craft custom heat pipes to solve your cooling challenges. Ready to boost your system’s performance? Contact us today at Kenfa Tech for a free consultation and see how our solutions can make a difference!