Electronics are all around us, from smartphones to electric cars. But did you know these devices get hot when they work? If that heat isn’t handled, it can slow down or even break your gadgets. That’s where heat sinks come in! Heat sinks are like superheroes that keep electronics cool by moving heat away. In this guide, we’ll explore heat sink design fundamentals in a way that’s easy to understand, even for a 12-year-old. Whether you’re curious or building something cool, you’ll learn how heat sinks work and why they matter. Plus, we’ll show how KenFa Tech creates awesome heat sinks for all kinds of devices.

Key Takeaway: Top 5 Things to Know About Heat Sink Design

| Key Point | Explanation |

|---|---|

| What is a heat sink? | A device that cools electronics by moving heat to the air. |

| Why material matters | Aluminum and copper conduct heat differently, affecting cooling. |

| Importance of airflow | Airflow carries heat away, making heat sinks more effective. |

| Manufacturing methods | Techniques like extrusion and machining create different heat sinks. |

| Why choose KenFa Tech | KenFa Tech designs custom, reliable heat sinks for many industries. |

What Is a Heat Sink and Why Does It Matter?

Keeping Electronics Cool

Have you ever felt your phone or laptop get warm after playing a game? That’s because electronic parts, like chips, create heat when they work. If they get too hot, they can slow down or stop working. A heat sink is a special device that takes this heat away, keeping your electronics safe and running smoothly.

How Heat Sinks Help

Think of a heat sink like a car’s radiator. It absorbs heat from a hot component and releases it into the air. This is super important for devices like computers, gaming consoles, and even electric car batteries. Without heat sinks, our gadgets wouldn’t last long. For example, KenFa Tech designs heat sinks for battery module cooling, ensuring batteries stay safe and efficient.

Why Design Matters

Not all heat sinks are the same. A good heat sink is designed to fit the device perfectly, considering how much heat it needs to handle and where it’s used. Poor design can lead to overheating, so experts like those at KenFa Tech use advanced tools to create reliable solutions. Their work helps everything from phones to big servers stay cool.

“Effective heat sink design is critical for the longevity and performance of modern electronics,” says Dr. John Smith, a thermal management expert. This shows why understanding heat sink design fundamentals is so important.

How Do Heat Sinks Work? The Key Principles

Three Ways to Move Heat

Heat sinks cool electronics by moving heat away from hot parts. They do this in three ways: conduction, convection, and radiation. Let’s break them down simply.

- Conduction: Heat travels through the heat sink’s material, like heat moving from a hot pan to a metal spoon. The heat sink’s base grabs heat from the component and spreads it to the fins.

- Convection: Air carries heat away from the heat sink’s fins. More fins mean more surface for air to touch, so heat escapes faster. Fans can help push air for better cooling.

- Radiation: Heat leaves as invisible waves, like warmth from a campfire. This is less important but still helps, especially when things get really hot.

A Simple Analogy

Imagine a hot cookie sheet fresh from the oven. If you touch it with a spatula, heat moves to the spatula (conduction). Blowing air over it cools it faster (convection). Leaving it out lets it slowly cool on its own (radiation). A heat sink uses all three to keep electronics cool.

Optimizing Heat Transfer

At KenFa Tech, engineers design heat sinks to make these processes work together perfectly. For example, their high-performance heat sinks are built to handle tough cooling needs, like in big data servers. By understanding heat sink design fundamentals, they ensure devices stay cool and reliable.

Choosing the Right Material for Heat Sinks

Why Material Matters

The material of a heat sink decides how well it can move heat. The key is thermal conductivity, which is how easily heat travels through something. Two popular materials are aluminum and copper, and each has its strengths.

Aluminum: The Popular Choice

Aluminum is used in most heat sinks because it’s lightweight, affordable, and pretty good at conducting heat. KenFa Tech often uses aluminum 6063 alloy, which is great for making heat sinks through aluminum extrusion. It’s perfect for devices like laptops or LED lights where weight and cost matter.

Copper: The High-Performer

Copper is even better at conducting heat—almost twice as good as aluminum. But it’s heavier and more expensive. That’s why copper is used in special cases, like aerospace or super-fast computers, where cooling is critical. KenFa Tech offers copper heat sink solutions for these high-demand applications.

Comparing Aluminum and Copper

- Aluminum:

- Pros: Lightweight, cheap, easy to shape.

- Cons: Not as good at conducting heat as copper.

- Copper:

- Pros: Excellent heat conduction, great for high performance.

- Cons: Heavy, expensive.

Sometimes, heat sinks combine both, like a copper base with aluminum fins, to get the best of both worlds. KenFa Tech’s experts help pick the right material for your needs, ensuring top cooling without breaking the bank.

Connecting Heat Sinks to Devices

Heat sinks need to be attached to electronic parts to work properly. If there’s a gap between the heat sink and the device, heat can’t move well, and the device might overheat. Let’s explore how engineers make sure heat sinks and devices stay connected for awesome cooling.

Why Good Contact Matters

Even if a heat sink looks perfect, it won’t work well if it’s not touching the device properly. Tiny gaps between the heat sink and the electronic part can trap heat because air doesn’t carry heat as well as metal does. These gaps are too small to see, but they make a big difference. That’s why engineers use special tricks to make sure heat moves smoothly from the device to the heat sink.

Using Thermal Interface Materials

Thermal interface materials, or TIMs, are like magic helpers for heat sinks. They fill those tiny gaps to help heat move better. TIMs can be things like thermal paste, which is a bit like toothpaste, or thermal pads, which are like sticky stickers. For example, thermal paste is often used in computers to connect the heat sink to the CPU. KenFa Tech uses high-quality TIMs to make sure their heat sinks, like those for inverter heat sinks, work perfectly.

Attaching the Heat Sink

Heat sinks also need to be held in place so they don’t move around. Engineers use screws, clips, or special glue to keep the heat sink attached to the device. This makes sure the heat sink stays in contact with the part that gets hot. For example, in a car battery system, a heat sink might be clipped onto the battery to keep it cool. KenFa Tech makes sure their heat sinks are attached securely, so heat moves without any problems.

Ensuring Long-Lasting Performance

A good connection doesn’t just help with cooling—it also makes the device last longer. If heat can’t escape, the device might break down faster. KenFa Tech tests their heat sinks to make sure the connection stays strong over time, even in tough conditions. “A secure connection is key to effective heat sink design,” says a thermal expert from KenFa Tech. Their careful work keeps devices running smoothly for years.

How Are Heat Sinks Made?

Heat sinks aren’t just magic—they’re made using special methods to create the perfect shape for cooling. Different methods make different kinds of heat sinks, depending on what the device needs. Let’s look at how heat sinks are made and how KenFa Tech does it!

Extrusion: Shaping with Pressure

Extrusion is a popular way to make heat sinks, especially with aluminum. It’s like squeezing toothpaste out of a tube. Hot aluminum is pushed through a mold to create long shapes with fins. These shapes are then cut into smaller pieces to make heat sinks. Extrusion is great for simple designs and making lots of heat sinks quickly. KenFa Tech uses aluminum extrusion to make affordable heat sinks for things like LED lights.

CNC Machining: Precision Cutting

CNC machining is like using a super-smart robot to carve out heat sinks. It uses tools to cut, drill, and shape metal into exact designs. This method is perfect for making complex heat sinks that need to fit specific devices. For example, a heat sink for a medical device might need a unique shape that extrusion can’t make. KenFa Tech uses CNC machining to create detailed designs for their medical device heat sinks.

Die Casting: Making Complex Fins

Die casting is another cool method. It’s like pouring hot metal into a mold to make a toy. Molten aluminum is injected into a mold under pressure, creating heat sinks with thin, dense fins. This method is great for making complicated shapes that cool really well. KenFa Tech uses die casting for heat sinks that need to handle a lot of heat, like those in electric car systems.

Our Manufacturing Magic

KenFa Tech is a pro at making heat sinks because they use all these methods and more. They also do things like heat pipe soldering and brazing to make their heat sinks even better. Plus, they test every heat sink to make sure it works perfectly. Whether it’s for a small phone or a big server, KenFa Tech’s manufacturing makes sure their heat sinks are top-quality.

Designing Heat Sinks for Tough Conditions

Heat sinks don’t just sit in a cozy room—they have to work in tough places like hot deserts or dusty factories. Engineers need to design heat sinks that can handle these hard conditions. Let’s see how they do it and how KenFa Tech makes sure their heat sinks are tough!

Facing High Temperatures

Some devices, like those in electric cars or wind turbines, get really hot. Heat sinks need to work even when temperatures are super high. Engineers pick materials like aluminum or copper that can handle the heat without breaking down. KenFa Tech designs heat sinks for wind power heat sinks that stay strong even in hot conditions.

Dealing with Dust and Dirt

Dust and dirt can be a big problem for heat sinks. If dust gets stuck in the fins, air can’t flow well, and the heat sink won’t cool as much. Engineers design heat sinks with shapes that let dust fall off easily, or they add filters to keep dust out. For example, a heat sink in a factory might need extra protection. KenFa Tech makes sure their heat sinks work well, even in dusty places.

Protecting Against Rust

Humidity and water can make heat sinks rust over time, which makes them less effective. To stop this, engineers use special coatings, like chromate coating, to protect the heat sink. It’s like putting a raincoat on the heat sink! KenFa Tech adds these coatings to their heat sinks so they last longer, even in wet or humid places.

KenFa Tech’s Tough Designs

We knows how to make heat sinks that can handle tough conditions. They test their heat sinks to make sure they work in extreme heat, dust, and humidity. For example, their heat sinks for renewable energy systems are built to last in harsh environments. “We design for durability so our heat sinks keep cooling no matter what,” says a KenFa Tech engineer. Their tough designs make devices reliable for a long time.

Keeping Costs Low in Heat Sink Design

Making a great heat sink doesn’t have to cost a lot of money. Engineers can design heat sinks that work well and save money at the same time. Let’s see how they keep costs low while still making awesome heat sinks!

Choosing Affordable Materials

The material of a heat sink can change how much it costs. Aluminum is much cheaper than copper, and it still works really well for most devices. By using aluminum, engineers can save money without making the heat sink less effective. KenFa Tech often uses aluminum to keep costs low for their aluminum heat sinks.

Simplifying Manufacturing

Some manufacturing methods cost more than others. For example, extrusion is cheaper than CNC machining because it’s faster and easier for simple shapes. By picking the right method, engineers can save money. KenFa Tech uses methods like extrusion to make lots of heat sinks quickly and cheaply, passing the savings to their customers.

Designing for Easy Production

Heat sinks that are simple to make are also cheaper. If a heat sink has a complicated shape, it takes more time and money to produce. Engineers try to keep designs simple while still making sure the heat sink cools well. KenFa Tech is great at designing heat sinks that are easy to make but still work perfectly for devices like inverters.

Our Cost-Saving Solutions

KenFa Tech knows how to balance cost and performance. They use affordable materials and smart designs to make heat sinks that don’t cost a lot but still cool really well. “We focus on cost-effective solutions without cutting corners,” says a KenFa Tech expert. This means customers get great heat sinks without spending too much money.

What’s New in Heat Sink Design? Market Trends

Heat sinks are becoming more important than ever because electronics are everywhere! Let’s look at what’s new in the world of heat sinks and how KenFa Tech is part of these exciting changes.

Growing Demand for Heat Sinks

More devices need heat sinks now, like electric cars, data centers, and solar panels. These devices make a lot of heat, so they need good cooling to work well. The global heat sink market was worth $7.10 billion in 2023 and is growing at 7.5% every year from 2024 to 2030. That’s a lot of heat sinks!

Aluminum Heat Sinks Lead the Way

Aluminum heat sinks are super popular because they’re affordable and easy to make. In 2025, the aluminum heat sink market is worth $7.38 billion and growing at 3.3% each year until 2033. Most heat sinks for electronics, like phones and computers, are made of aluminum because it works well and saves money.

Active Cooling Is Growing Fast

Active cooling, like using fans with heat sinks, is becoming more common. It cools better than passive cooling, which doesn’t use fans. This is important for devices that get really hot, like servers in data centers. KenFa Tech makes heat sinks for both active and passive cooling, so they can help with all kinds of devices.

Role in Trends of KenFa Tech

KenFa Tech is a leader in these trends. They make heat sinks for growing industries like electric vehicles and renewable energy. For example, their EV heat sinks help keep car batteries cool. By staying ahead of trends, KenFa Tech makes sure their customers get the best cooling solutions.

KenFa Tech’s Heat Sink Design Success Story

KenFa Tech is a company that’s really good at making heat sinks. Let’s look at how they help devices stay cool and why they’re so great at what they do!

Who Is KenFa Tech?

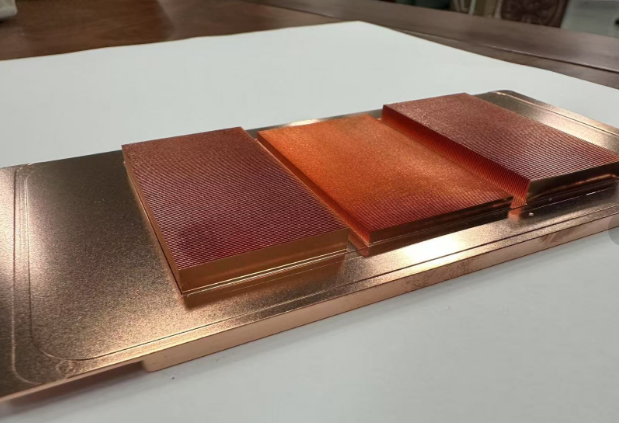

KenFa Tech is a high-tech company with over 10 years of experience making heat sinks and liquid cold plates. They help cool all kinds of devices, from big data servers to electric car batteries. They’re known for creating smart solutions that keep electronics safe and working well.

Using Advanced Tools

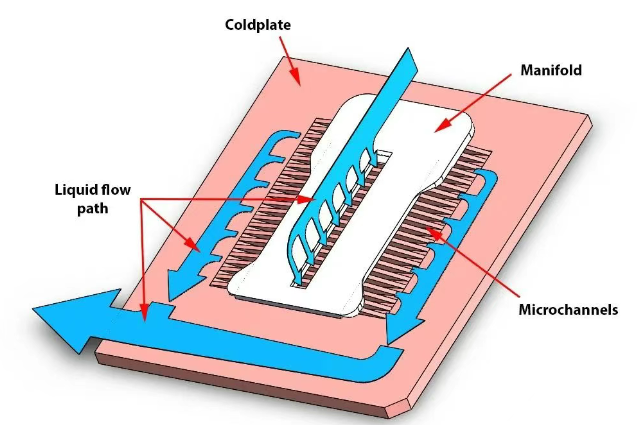

KenFa Tech uses special computer programs like Ansys and Flothermal to design their heat sinks. These tools let them test how well a heat sink will work before they even make it. This means they can create heat sinks that cool perfectly for each device, like their liquid cold plates for 280Ah battery mobile.

Top-Notch Manufacturing

KenFa Tech has amazing ways to make heat sinks, like CNC machining, heat pipe soldering, and brazing. They also test every heat sink to make sure it works great, checking things like thermal resistance and leaks. This makes their heat sinks super reliable for industries like wind power and solar energy.

Why Customers Love KenFa Tech

KenFa Tech stands out because they focus on quality and customer needs. They have certifications like ISO9001 and IATF16949, which means they follow strict rules to make great products. They also deliver on time and offer cost-effective solutions. Customers trust KenFa Tech to keep their devices cool and running smoothly.

Frequently Asked Questions About Heat Sink Design

Got questions about heat sinks? Here are some common ones with simple answers to help you understand!

What Materials Are Best for Heat Sinks?

Aluminum is great because it’s cheap and lightweight, perfect for most devices. Copper is better at moving heat but costs more and is heavier, so it’s used for high-performance devices like super-fast computers.

How Do You Size a Heat Sink?

Engineers figure out how much heat the device makes, then design a heat sink with enough surface area to move that heat away. They use math and computer tools to get the size just right.

What’s the Difference Between Passive and Active Heat Sinks?

Passive heat sinks use natural air movement to cool, so they’re quiet but less powerful. Active heat sinks use fans to push air, cooling better but making noise.

How Does Airflow Affect Performance?

Good airflow helps heat escape from the heat sink. If air can’t move well, heat gets trapped, and cooling doesn’t work as well. That’s why fins are spaced to let air flow easily.

What Methods Are Used to Make Heat Sinks?

Heat sinks are made with methods like extrusion for simple shapes, CNC machining for detailed designs, and die casting for complex fins. Each method fits different cooling needs.

Ready to Cool Your Devices? Contact KenFa Tech!

Now you know all about heat sink design fundamentals and how they keep electronics cool! Whether it’s a computer, car battery, or solar panel, a good heat sink makes a big difference. KenFa Tech is here to help with amazing heat sinks that fit your needs.

Need a custom heat sink for your project? Visit KenFa Tech’s website to learn more about their cooling solutions. They can design, build, and test heat sinks for any device, making sure everything stays cool and works great. Contact KenFa Tech today and keep your electronics happy!

Conclusion: Stay Cool with Smart Heat Sink Design

Heat sinks are super important for keeping our electronics safe and working well. From picking the right material to designing the perfect shape, every step in heat sink design matters. We’ve learned how heat moves, why airflow helps, and how KenFa Tech makes awesome heat sinks for all kinds of devices.

With over 10 years of experience, KenFa Tech knows how to create heat sinks that are tough, affordable, and perfect for modern needs like electric cars and data centers. Ready to cool your devices the smart way? Check out KenFa Tech for the best heat sink solutions. Let’s keep our electronics cool and ready for action!

External Resources for Further Reading

- Electronics Cooling: Heat Sink Design Guide – A detailed guide on heat sink design principles.

- IEEE: Thermal Management in Electronics – Research on thermal management trends in electronics.