The core content of this article is to explain the characteristics of aluminum alloy vacuum brazing process,Overview of the basic characteristics and vacuum brazing of two types of aluminum alloys 3003 and 6o61.

3003 aluminum alloy is an Al-Mn series alloy, which has good corrosion resistance and formability, but cannot be strengthened by heat treatment. 6061 aluminum alloy is an Al-Mg-Si series alloy, which can be strengthened by heat treatment, and has high strength, good processing performance and excellent welding performance. Vacuum brazing is a brazing process carried out in a vacuum environment (usually with a pressure ≤10⁻³ Pa). It does not require flux and can avoid the oxidation of the base metal and filler metal, thus obtaining clean and high-quality welds. It is particularly suitable for the connection of precision parts and dissimilar materials.

Detailed Explanation of Vacuum Brazing Characteristics of 3003 and 6061 Aluminum Alloys

3003 Alloy: It has good vacuum brazing performance, which benefits from the presence of manganese (Mn). Mn can increase the recrystallization temperature and refine the grains. However, it is necessary to control the brazing temperature (e.g., in the range of 580 – 590°C) and holding time to prevent the base metal from being excessively corroded by the filler metal, especially in thin – walled structures such as honeycomb panels.

6061 aluminum alloy: The main challenge in vacuum brazing lies in the magnesium (Mg) element it contains. Mg is prone to evaporation at the brazing temperature, which is somewhat contrary to the original intention of the vacuum environment to remove the oxide film. The evaporation of Mg will: Pollute the vacuum chamber.Generally speaking, when designing and producing liquid cold plates or heat sinks made of 6061 aluminum alloy through vacuum brazing, it is necessary to precisely control the temperature (e.g., 588°C) and holding time to balance the volatilization of Mg (an appropriate amount of Mg is required to promote the flow of the brazing filler metal) and prevent problems caused by excessive volatilization.

Key parameters and control points of vacuum brazing process

4004 filler metal (Al – Si – Mg): It is a common choice for brazing 3003 and 6061 aluminum alloys, with a melting point of approximately 559–591°C. Special low-melting-point brazing filler metals: For heat-treatable strengthened aluminum alloys such as 6061, research shows that using Al-Si-Cu-Mg brazing filler metals with specific compositions or low-melting-point brazing filler metals (melting point: 514–538℃) prepared by melt quenching technology helps to avoid overburning and grain growth of the base metal and obtain high-quality joints.

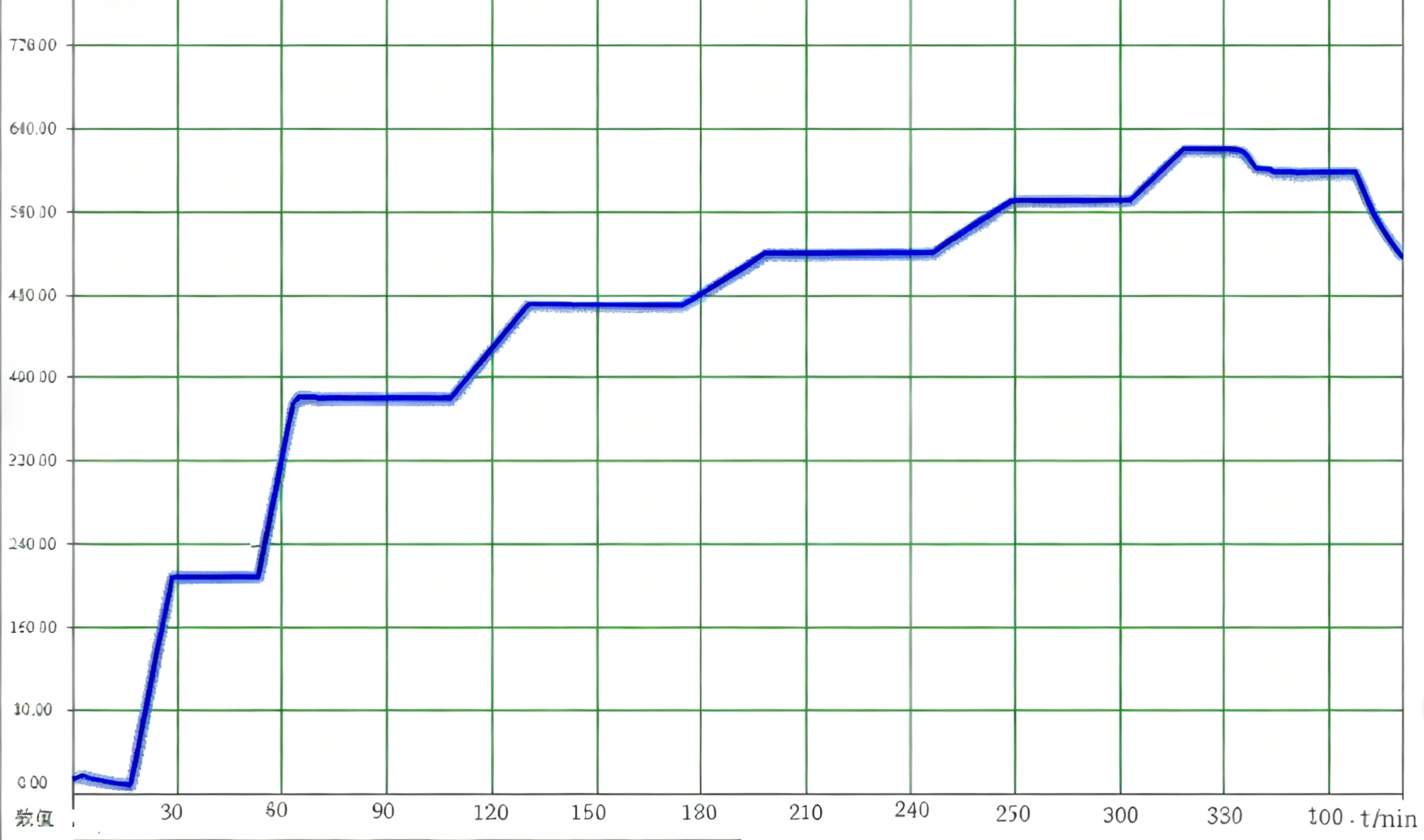

As shown in Figure 1 above, temperature is one of the most crucial parameters. If the temperature is too low, it may result in insufficient melting and poor fluidity of the brazing filler metal. If the temperature is too high, it can easily cause corrosion of the base metal (in severe cases, the 3003 honeycomb core nearly completely dissolves at 595°C), grain growth, or excessive volatilization of Mg elements. The holding time needs to be coordinated with the temperature. For example, for domestic 6061 with a relatively low Mg content, it may be necessary to appropriately extend the holding time (e.g., 12 minutes) to promote the flow of the brazing filler metal and the diffusion of alloy elements.

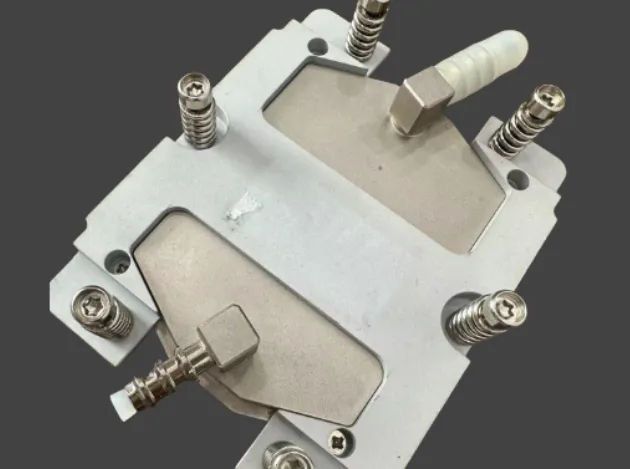

Degree of vacuum: A high degree of vacuum (usually required to be ≤10⁻³ Pa) can effectively remove the oxide film and prevent the workpiece from oxidation, which is a prerequisite for obtaining clean welds.Surface condition of the base metal and assembly clearance: The surface to be welded must be clean, free of oil and oxide layers. The assembly clearance should be suitable for the capillary flow of the filler metal.Tooling fixtures: A reasonable tooling design can effectively control welding deformation, ensure the relative positions between parts, and promote heat conduction.These are particularly crucial for the battery pack liquid-cooled plates corresponding to production thermal management. A tiny leak can have catastrophic consequences for the battery modules cooling.

Common defects and solutions

Solder overflow (improper flow of brazing filler metal): The brazing filler metal accumulates outside the weld area, affecting the appearance and assembly.Reasons: Excessively high brazing temperature, too long holding time, excessive amount of brazing filler metal, small grain size of the base metal (more grain boundaries provide channels for the flow of the brazing filler metal), etc.Solution: Optimize the brazing parameters. For 3003/6063 composite materials, the grain size of the base metal can be increased through processes (such as adding intermediate annealing) to reduce the grain boundaries, thereby suppressing the excessive flow of the brazing filler metal.

Erosion: The base metal is locally and excessively dissolved in the liquid filler metal, and holes are formed in severe cases.

Reasons: The brazing temperature is too high, the holding time is too long, and the melting points of the filler metal and the base metal are too close.Solutions: Strictly control the brazing temperature at the lower limit of the recommended range to avoid over – temperature; select a filler metal with a suitable melting point.

Poor weld formation: including incomplete fillet, lack of penetration, porosity, etc.Causes: Insufficient temperature, insufficient vacuum, poor surface cleanliness, improper assembly clearance, insufficient or excessive Mg volatilization affecting wettability (for 6061).Solution: Ensure vacuum; clean the surface to be soldered; optimize assembly; for 6061, precise control of Mg behavior is required.

Process selection and optimization suggestions

Material selection strategy: If the product does not need to bear extremely high loads, but requires good formability, corrosion resistance, and economy (such as heat exchangers and some honeycomb structures), 3003 aluminum alloy is a better choice, as it has a relatively wide vacuum brazing process window. If the product requires high strength and stiffness and can undergo heat treatment for strengthening (such as aerospace structural parts and high – load radiator boxes), then 6061 aluminum alloy should be selected. However, one has to accept the fact that its vacuum brazing process is more complex and has higher control requirements.

Process optimization directions:

For 3003: Focus on controlling the brazing temperature to prevent corrosion and reducing the overflow of brazing filler metal through tooling design and parameter optimization.For 6061: The core is to control the influence of Mg element. This includes:

Selecting base metals and brazing filler metals with appropriate Mg content.Precisely controlling the brazing temperature and holding time to balance the volatilization of Mg and the wetting of the brazing filler metal.Paying attention to the cleanliness of the furnace atmosphere to avoid contamination by Mg volatiles.Considering post – weld heat treatment (T6) to further improve the joint strength.

In general, 3003 aluminum alloy liquid cold plates or heat sinks generally offer better vacuum brazing processability than 6061 aluminum alloy. Because it contains no volatile magnesium, process control is relatively simple and less sensitive to parameter fluctuations. While 6061 aluminum alloy liquid cold plates and heat sinks can achieve higher-strength joints due to its heat-treatable hardening properties, the vacuum brazing process requires more precise control of process parameters (particularly temperature and holding time) to manage Mg volatilization and avoid the associated problems. The ultimate choice depends on your specific application scenario, performance requirements (strength, corrosion resistance, appearance), and production conditions (equipment precision and process control capabilities). Through in-depth process testing and parameter optimization, satisfactory joints can be achieved with either material using vacuum brazing.

For any thermal management design, please email us directly and our engineers can answer your questions at king@kenfatech.com. We will respond to your thermal needs within 8 hours.