Introduction

The quest for efficient thermal management solutions has never been more crucial in today’s electronic landscape. Among the array of innovations in this field, KenFa Tech’s heat pipe heat sinks stand out as a remarkable technology that addresses the escalating thermal challenges electronic devices face.

Heat pipe heat sinks represent a sophisticated approach to thermal management. They capitalize on phase change and heat transfer principles to effectively dissipate heat. Unlike traditional heat sinks, which rely primarily on conduction and convection, heat pipe heat sinks employ a closed-loop system that efficiently transports heat away from electronic components.

The relentless march toward miniaturization and increased performance in electronic devices has led to higher power densities and, consequently, elevated temperatures. Left unchecked, these temperatures can degrade performance, reduce reliability, and even cause catastrophic failure. Therefore, effective thermal management is essential to ensure the longevity and reliability of electronic devices.

This article aims to comprehensively evaluate the effectiveness of KenFa Tech’s heat pipe heat sinks in addressing high thermal loads in electronic devices. By scrutinizing their design, operation, and performance characteristics, we seek to empower readers with the knowledge needed to make informed decisions when considering thermal management solutions.

II.Understanding Heat Pipe Heat Sinks

1. Definition and Basic Operation

Heat pipe heat sinks are advanced thermal management devices designed to dissipate heat generated by electronic components efficiently. They utilize the principles of phase change and heat transfer to achieve superior thermal performance.

The essential operation of a heat pipe heat sink relies on the phase change of a working fluid contained within the heat pipe. When heat is applied to one end of the pipe, the working fluid evaporates into vapor, absorbing thermal energy. This vapor travels along the length of the heat pipe to a more excellent region, where it condenses back into liquid form, releasing the absorbed heat. The condensed liquid returns to the heat source via capillary action or gravity, completing the cycle.

2. Components and Structure

A typical heat pipe heat sink consists of several key components, including:

- Heat pipe: A sealed, evacuated tube containing a small amount of working fluid.

- Evaporator: The section of the heat pipe where heat is applied causes the working fluid to evaporate.

- Condenser: The section of the heat pipe where the vapor condenses back into liquid form, releasing heat.

- Wick structure: Internal or external structures that facilitate the return of condensed liquid to the evaporator.

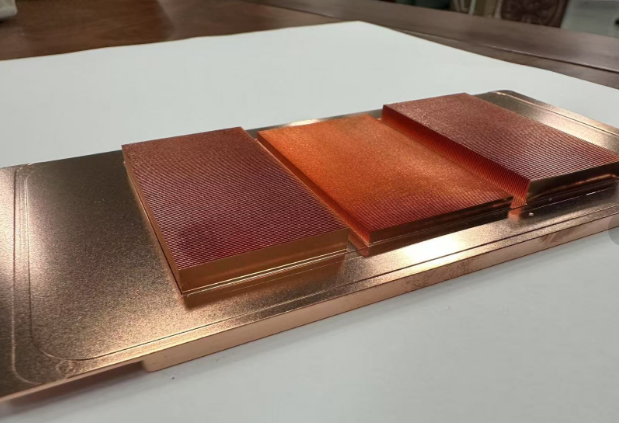

The structure of a heat pipe heat sink is designed to maximize heat transfer efficiency while minimizing thermal resistance. Depending on the application requirements, various materials, such as copper, aluminum, or composite materials, may be used to construct the heat pipe and its surrounding components.

3. Types of Heat Pipe Heat Sinks

There are several types of heat pipe heat sinks designed to suit different applications and thermal requirements:

- Conventional heat pipe heat sinks: Standard heat pipe configurations suitable for general-purpose thermal management.

- Vapor chamber heat sinks: Flat, planar heat pipes that offer enhanced heat spreading capabilities.

- Loop heat pipes: Closed-loop heat pipe systems with additional features such as multiple evaporators and condensers for complex thermal management tasks.

Each heat pipe heat sink type offers unique advantages and may be selected based on space constraints, thermal performance goals, and environmental conditions.

III.Factors Affecting Effectiveness of Heat Pipe Heat Sinks

1. Thermal Conductivity of Materials Used

The thermal conductivity of the materials used in constructing heat pipe heat sinks is critical in determining their effectiveness. Materials with higher thermal conductivity facilitate better heat transfer from the heat source to the heat pipe, allowing for more efficient thermal energy dissipation. Commonly used materials include copper, aluminum, and various alloys, with copper being favored for its exceptional thermal conductivity. Manufacturers often select materials based on cost, weight, and compatibility with the application environment.

2. Surface Area and Fin Design

A heat pipe heat sink’s surface area and fin design significantly influence its ability to dissipate heat. Increasing the heat sink’s surface area enhances heat transfer by providing more contact area for heat dissipation. Additionally, designing fins or other heat-dissipating structures can impact airflow and convection, further improving thermal performance. Manufacturers employ techniques such as increasing fin density, optimizing fin geometry, and incorporating heat pipes into intricate heat sink designs to maximize surface area and enhance heat dissipation efficiency.

3. Operating Temperature Range

The operating temperature range is another crucial factor affecting the effectiveness of heat pipe heat sinks. Different applications may require heat sinks to operate within specific temperature limits to ensure optimal performance and reliability. Heat pipes and other components must be selected or designed to withstand the temperatures encountered in the intended operating environment. Manufacturers may employ thermal simulations and testing to determine the suitability of their heat sink designs across a range of operating conditions, ensuring compatibility with diverse application requirements.

4. Environmental Conditions

Environmental conditions, such as humidity, altitude, and contaminants, can impact the effectiveness of heat pipe heat sinks. High humidity levels may affect the performance of heat pipe wicks or promote corrosion of heat sink materials, leading to reduced thermal efficiency and reliability. Similarly, operating at high altitudes can affect heat transfer rates due to air density and pressure changes. Manufacturers must consider these environmental factors during the design and testing phases to ensure the robustness and longevity of their heat sink solutions across diverse operating environments.

IV.Performance Evaluation of Heat Pipe Heat Sinks

1. Comparison with Traditional Heat Sinks

When evaluating the performance of heat pipe heat sinks, it is essential to compare them with traditional heat sink solutions. Conventional heat sinks typically rely on conduction and convection to dissipate heat, whereas heat pipe heat sinks utilize phase change and heat transfer mechanisms for more efficient thermal management. Heat pipe heat sinks often demonstrate superior heat dissipation capabilities thanks to their ability to transport heat over longer distances with minimal temperature gradients. Additionally, heat pipe heat sinks can offer more uniform temperature distribution across electronic components, reducing the risk of hot spots and improving overall system reliability.

2. Case Studies or Examples Showcasing Effectiveness

Case studies and real-world examples provide valuable insights into the effectiveness of heat pipe heat sinks in various applications. These examples can highlight electronic devices’ specific challenges and demonstrate how heat pipe heat sinks successfully mitigate thermal issues. For instance, in a high-performance CPU case study, implementing a heat pipe heat sink resulted in significant temperature reductions under heavy load conditions, ensuring stable operation and prolonging the processor’s lifespan. Similarly, examples from industries such as aerospace and automotive can showcase the versatility and reliability of heat pipe heat sinks in extreme environments and demanding operating conditions.

3. Efficiency in Dissipating High Thermal Loads

One of the primary advantages of heat pipe heat sinks is their efficiency in dissipating high thermal loads. Heat pipe heat sinks can effectively manage the heat generated by high-power devices such as GPUs, CPUs, and power electronics by efficiently transferring heat away from electronic components. This efficiency is crucial in applications where thermal management is paramount, such as data centers, telecommunications equipment, and industrial machinery. Heat pipe heat sinks excel in dissipating high thermal loads while maintaining low thermal resistance, ensuring optimal performance and reliability of electronic systems even under demanding operating conditions.

V.Advantages and Limitations of Heat Pipe Heat Sinks

A.Advantages of Heat Pipe Heat Sinks

1. Enhanced Heat Dissipation Efficiency

Heat pipe heat sinks offer superior heat dissipation efficiency compared to traditional heat sinks. Their ability to transfer heat over longer distances with minimal temperature gradients allows for more effective thermal management.

2. Compact Design

Heat pipe heat sinks can be designed to be more compact than traditional heat sinks while providing comparable or even superior thermal performance. This compactness is particularly advantageous in applications where space is limited.

3. Uniform Temperature Distribution

By efficiently distributing heat across the heat sink’s surface, heat pipe heat sinks help maintain uniform temperature distribution in electronic devices. This reduces the risk of hot spots and ensures more consistent performance.

4. Versatility

Heat pipe heat sinks are versatile and can be customized to meet the specific requirements of various applications. They can be integrated into complex thermal management systems and adapted to different form factors.

B.Limitations and Constraints

1. Cost

Heat pipe heat sinks can be more expensive to manufacture than traditional heat sinks due to their complex design and the use of specialized materials. This cost consideration may be a limiting factor for some applications, especially those with budget constraints.

2. Condensation Concerns

Condensation may occur within the heat pipe in environments with high humidity levels, potentially compromising its performance and longevity. Proper design and materials selection can help mitigate this risk, but it remains a consideration in humid environments.

3. Operating Orientation

Their operating Orientation may influence the effectiveness of heat pipe heat sinks. In some cases, gravity-assisted heat pipe designs may be required to ensure optimal performance, especially in applications where the Orientation is not fixed.

C.Considerations for Specific Applications

1. Aerospace and Automotive

Heat pipe heat sinks offer significant advantages in aerospace and automotive applications, where weight and space constraints are critical. Their compact design and high heat dissipation efficiency make them ideal for cooling electronic components in these industries.

2. Data Centers

In data center environments, where cooling efficiency directly impacts energy consumption and operational costs, heat pipe heat sinks play a crucial role. Their ability to dissipate high thermal loads efficiently helps maintain optimal operating temperatures for servers and networking equipment, contributing to overall energy savings.

3. Industrial Machinery

In industrial settings, where equipment reliability is paramount, heat pipe heat sinks can help prolong the lifespan of electronic components by effectively managing heat dissipation. Their robust construction and ability to withstand harsh operating conditions make them well-suited for industrial machinery applications.

VI.Recommendations for Users

A.Choosing the Right Heat Pipe Heat Sink for Specific Requirements

When selecting a heat pipe heat sink for your specific application, consider the following factors:

1. Thermal Requirements

Determine your electronic device’s thermal performance requirements and select a heat pipe heat sink with adequate heat dissipation capacity to meet those requirements.

2. Form Factor and Size Constraints

Consider the available space for heat sink installation and choose a design that fits those constraints while still providing optimal thermal management.

3. Operating Conditions

Evaluate the operating environment, including temperature, humidity, and vibration levels, to ensure that the selected heat pipe heat sink can withstand these conditions without compromising performance or reliability.

4. Compatibility with Other Cooling Solutions

If your electronic device utilizes other cooling solutions, such as fans or liquid cooling systems, ensure compatibility and integration between the heat pipe heat sink and these components for optimal thermal performance.

B.Installation and Maintenance Tips

1. Proper Mounting

Ensure the heat pipe heat sink is securely mounted to the electronic component using appropriate mounting hardware to maximize heat transfer efficiency.

2. Avoiding Airflow Blockages

Ensure that the heat sink is installed in a location with sufficient airflow to facilitate heat dissipation. Avoid blocking airflow paths with cables or other obstructions.

3. Regular Cleaning

Periodically clean the heat sink and surrounding components to remove dust and debris, which can impede airflow and reduce thermal performance.

4. Monitoring for Signs of Degradation

Regularly monitor the performance of the heat pipe heat sink and electronic device for signs of degradation or malfunction, such as increased operating temperatures or decreased performance.

C.Potential Cost-Effectiveness Analysis

When considering the cost-effectiveness of heat pipe heat sinks, weigh the initial investment against the long-term benefits, including:

1. Energy Savings

Calculate potential energy savings resulting from improved thermal management and reduced cooling requirements, which can lead to lower operating costs over time.

2. Extended Lifespan of Electronic Components

Consider the potential cost savings associated with prolonging the lifespan of electronic components through effective heat dissipation, reducing the frequency of component replacements and maintenance.

3. Improved System Reliability

Factor in the cost savings resulting from improved system reliability and reduced downtime due to overheating-related failures, which can have significant financial implications for businesses.

4. Comparative Analysis

Conduct a comparative analysis of different heat pipe heat sink options, considering factors such as performance, durability, and manufacturer reputation, to identify the most cost-effective solution for your specific application.

VII.Future Trends and Developments

A.Emerging Technologies in Heat Pipe Heat Sink Design

As the demand for more efficient thermal management solutions continues to grow, several emerging technologies are shaping the future of heat pipe heat sink design:

1. Advanced Materials

Developing novel materials with enhanced thermal conductivity and durability revolutionizes heat pipe heat sink design. Graphene, carbon nanotubes, and other nanomaterials promise to improve heat transfer efficiency and reduce heat sink weight and size.

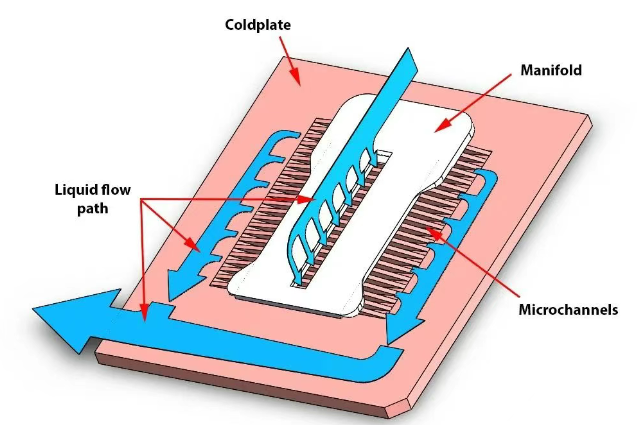

2. Microfluidic Cooling

Microfluidic cooling systems, which utilize tiny channels to circulate coolant fluid directly over heat-generating components, offer significant advantages regarding localized cooling and thermal efficiency. Integrating microfluidic cooling with heat pipe heat sinks could lead to more efficient thermal management solutions.

3. Additive Manufacturing

Additive manufacturing, or 3D printing, enables the rapid prototyping and customization of complex heat pipe heat sink designs. This technology allows for creating intricate heat sink geometries optimized for specific applications, leading to improved performance and thermal efficiency.

B.Predictions for Future Advancements

Looking ahead, several trends and advancements are expected to shape the future of heat pipe heat sink technology:

1. Increased Integration

Heat pipe heat sinks are likely to become more integrated with other cooling technologies, such as liquid cooling systems and phase change materials, to achieve even more excellent thermal performance and efficiency.

2. Miniaturization

Advancements in miniaturization techniques will enable the development of smaller, more compact heat pipe heat sinks suitable for portable electronic devices, wearable technology, and IoT devices.

3. Enhanced Sustainability

Future developments in heat pipe heat sink design will focus on improving sustainability by using eco-friendly materials, optimizing energy efficiency, and reducing environmental impact throughout the product lifecycle.

C.Implications for Electronic Device Manufacturers and Users

The evolving landscape of heat pipe heat sink technology will have significant implications for both manufacturers and users of electronic devices:

1. Improved Performance and Reliability

Manufacturers will be able to offer electronic devices with enhanced thermal performance and reliability, leading to improved overall product quality and customer satisfaction.

2. Energy Efficiency

Adopting advanced heat pipe heat sink technologies will increase energy efficiency in electronic devices, resulting in lower power consumption and reduced environmental footprint.

3. Design Flexibility

Advancements in heat pipe heat sink technology will enable greater design flexibility for users, allowing for the development of more innovative and compact electronic devices tailored to their specific needs and preferences.

VIII.Conclusion

The effectiveness of heat pipe heat sinks in dissipating heat from electronic devices cannot be overstated. Their ability to efficiently transfer heat away from components, compact design, and versatility make them indispensable in today’s electronics industry. As electronic devices become more powerful and compact, the importance of effective thermal management solutions like heat pipe heat sinks will only continue to grow.

As we look to the future, there is immense potential for further exploration and adoption of heat pipe heat sink technology. Manufacturers and researchers alike are encouraged to continue innovating in this field, exploring emerging technologies and pushing the boundaries of thermal management capabilities. By embracing heat pipe heat sinks and other advanced cooling solutions, we can unlock new possibilities in electronics design and create more efficient, reliable, and sustainable devices for the future.