Core Equipment for Reliability Verification: Technological Breakthroughs and Application Value of Liquid Cooled Plates Dedicated to AI Chip Test Fixtures

In the full process of AI chips from packaging to mass production, reliability verification is a key link that determines product yield and market competitiveness. With the thermal design power (TDP) of high-performance chips such as GB300 and HBM3e exceeding 2.7kW, traditional air-cooled test solutions can no longer meet the precise temperature control requirements in the packaging stage. As a core thermal management device, Liquid cold plates dedicated to test fixtures have become a rigid demand for chip manufacturers in the reliability verification link. They not only need to solve the heat dissipation problem of ultra-high-power chips but also provide a stable and precise temperature environment for early chip testing, directly determining the validity and reliability of test data.

I. Thermal Management Pain Points of AI Chip Test Fixtures: Why Liquid Cooled Plates Are a Must-Have

The packaging testing and reliability verification of AI chips have far higher requirements for thermal management than terminal application scenarios. Traditional heat dissipation solutions face three core pain points:

(1) Thermal Concentration Challenges Brought by 3D Packaging

As chips evolve from 2.5D packaging to 3D stacking architectures, vertically stacked active chips have led to an exponential increase in power density. Intermediate-layer chips are prone to thermal concentration due to blocked heat dissipation paths, with local heat flux density exceeding 1200W/cm². In the reliability test after packaging, such thermal concentration will cause fluctuations in chip performance and even lead to misjudgments of “qualified in testing but failed in actual application”. The heat dissipation efficiency of traditional air cooling can only cope with power consumption scenarios below 300W, which is completely unable to penetrate the thermal resistance barrier of 3D packaging.

(2) Precise Temperature Control Requirements for Reliability Testing

Chip reliability verification needs to simulate long-term full-load working conditions, including harsh test items such as 72-hour continuous operation and temperature cycling from -40℃ to 125℃. This requires heat dissipation equipment not only to quickly export heat but also to achieve precise temperature control of ±0.1℃ to avoid test data distortion caused by temperature fluctuations. The temperature uniformity of ordinary water-cooling schemes can only reach ±1℃, which cannot meet the stringent standards of chip yield testing. However, dedicated test fixture water-cooled plates can improve temperature uniformity by 48% through customized design.

(3) Integration and Adaptation Challenges of Test Fixtures

Test fixtures usually have compact spaces and complex interfaces. Heat dissipation equipment needs to adapt to different chip package sizes (such as CoWoS and Foveros) while avoiding interference with test probes and signal interfaces. The rigid structure and fixed flow channel design of traditional water-cooled plates make it difficult to match the test needs of multiple chip models. In contrast, dedicated Liquid cold plates need to have modular and lightweight characteristics to ensure close fitting while guaranteeing signal stability during testing.

Data shows that test fixtures using dedicated Liquid cold plates can reduce the misjudgment rate of AI chip reliability testing by 60% and shorten the test cycle by 40%, becoming a key equipment for chip manufacturers to improve mass production efficiency.

II. Core Technological Breakthroughs of Liquid Cooled Plates Dedicated to Test Fixtures: Customized Innovations Adapting to Test Scenarios

To address the special needs of AI chip testing, dedicated water-cooled plates have achieved three major technological breakthroughs in structural design, material processes, and function integration, forming unique advantages distinct from terminal applications:

(1) Structural Customization: Precisely Matching Test Fixtures and Chip Packages

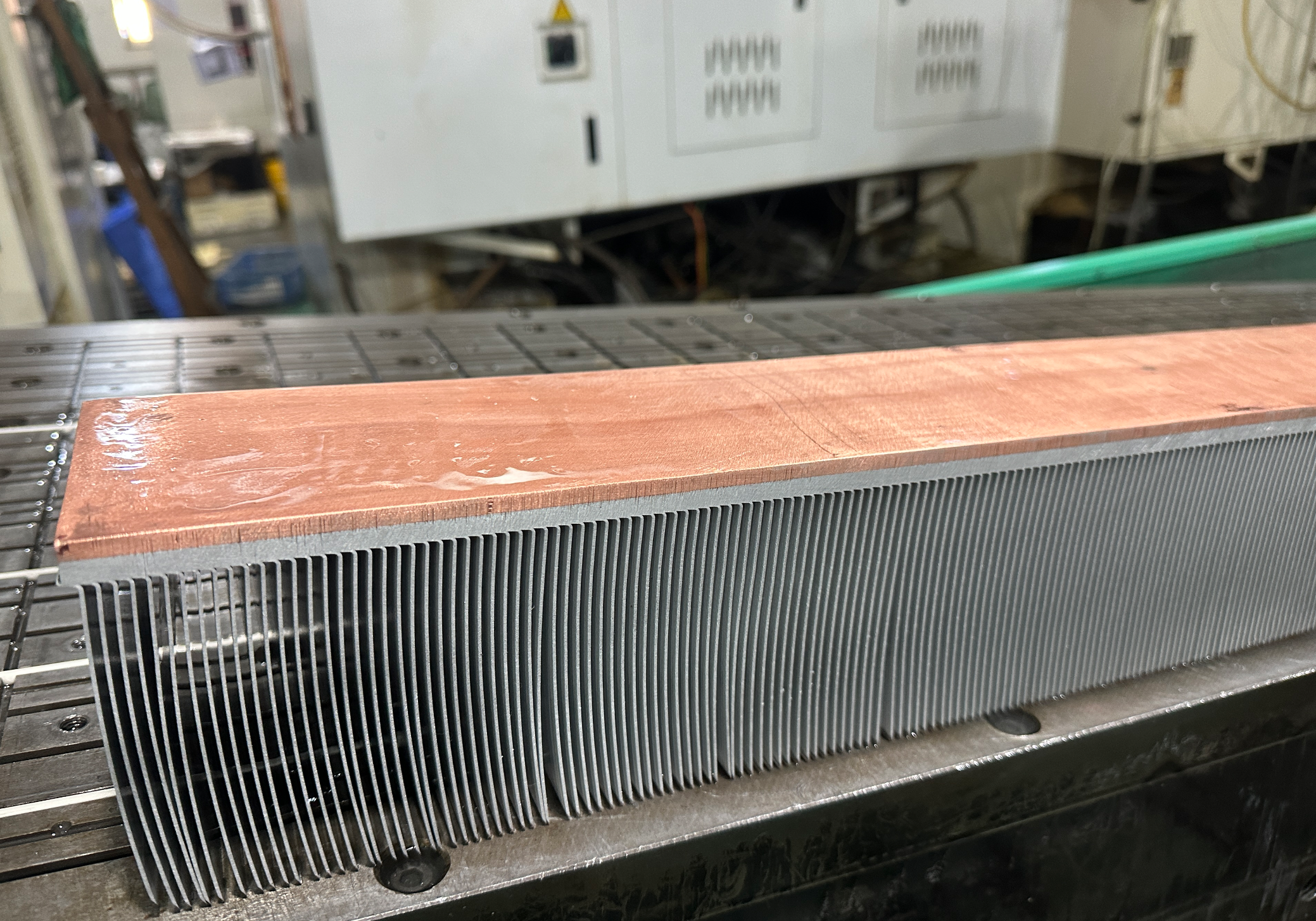

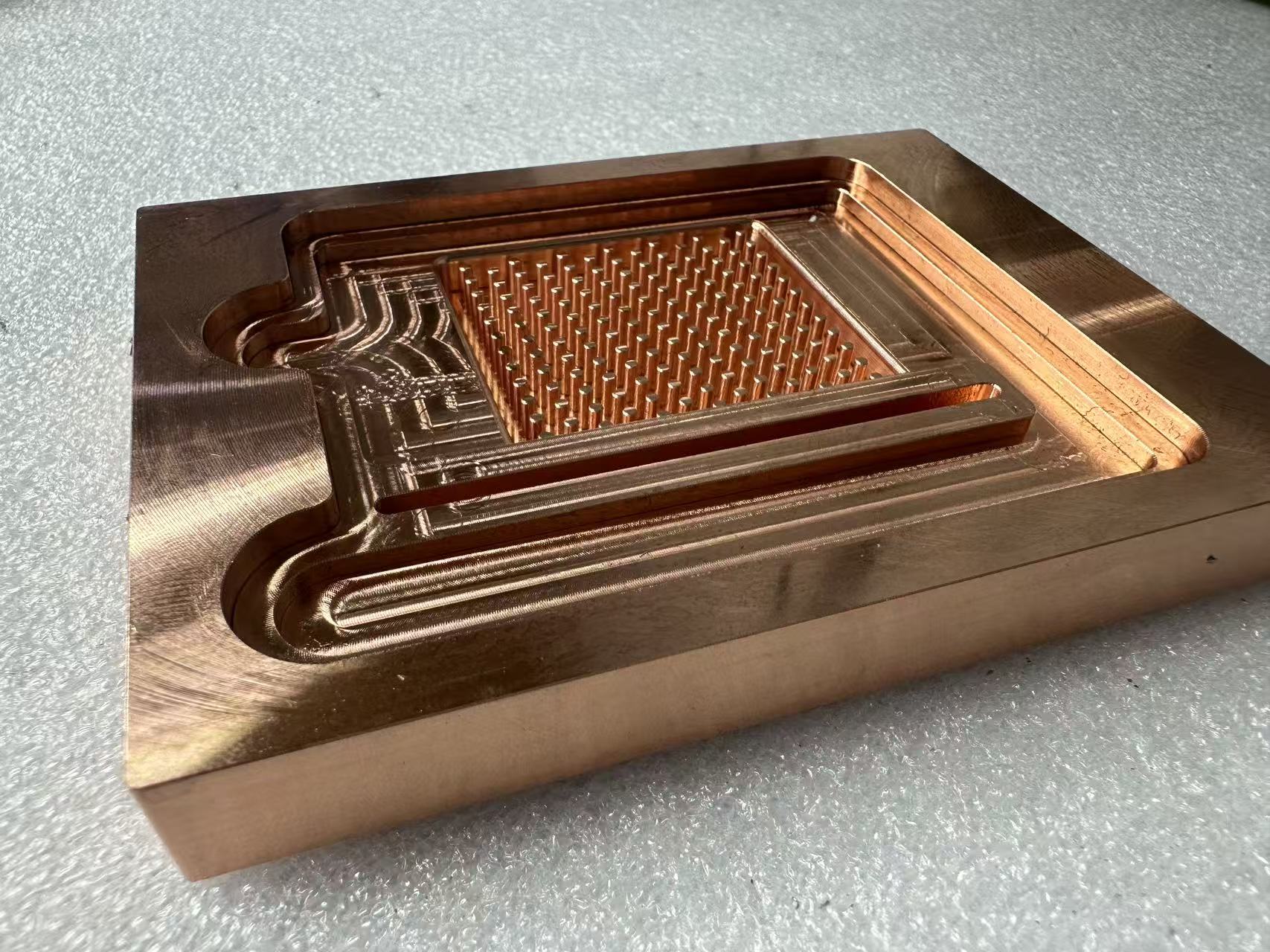

To address the thermal distribution of 3D packaging, dedicated Liquid cold plates feature a five-sided fitting cold head. This design allows heat dissipation from all sides, reducing thermal resistance by 500 times compared to traditional single-sided cold plates. The flow channel design is customized based on the chip thermal map, adopting a 33-micron-level 3D micro-grid structure to directly spray coolant to hot spot areas, ensuring uniform temperature of each layer of vertically stacked chips.

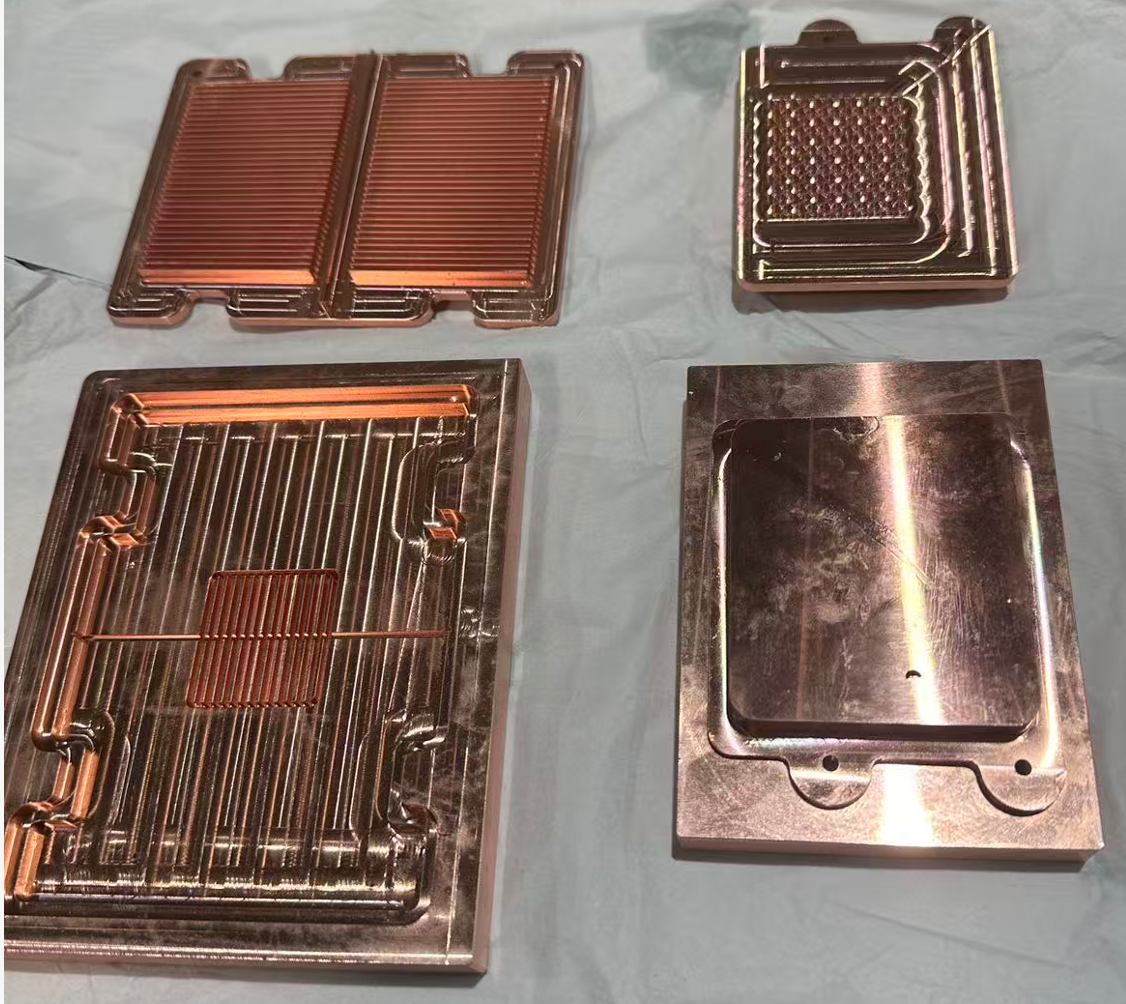

The modular design is key to adapting to various test fixtures. Liquid cold plates feature a replaceable contact panel that accommodates chip sizes from 7nm to 3nm. The flow channel layout is optimized to control pressure loss, ensuring a stable coolant flow rate below 1.5m/s and preventing component erosion.

(2) Materials and Processes: Balancing Heat Dissipation Efficiency and Test Safety

Material selection focuses on the dual needs of “high-efficiency heat conduction + safety and reliability”: the substrate uses 99.95% high-purity copper with a thermal conductivity of 400W/m·K, and combined with nano-silver sintering technology, it achieves high-efficiency heat transfer with a thermal resistance as low as 0.03℃·cm²/W. Targeting the electrochemical corrosion risk of test fixtures, all metal contact surfaces are treated with anti-corrosion measures to ensure that the electrochemical potential difference of the metal-metal interface does not exceed 0.15V.

In terms of manufacturing processes, the application of Electrochemical Additive Manufacturing (ECAM) technology has achieved a key breakthrough: this room-temperature deposition process can directly print cold plate structures on the surface of temperature-sensitive test fixtures, avoiding fixture deformation caused by thermal stress; at the same time, it can manufacture complex micro-flow channel structures, increasing the cold plate surface area by 900% and significantly improving heat exchange efficiency. In addition, the integrated seamless structure controls the leakage rate to <10⁻⁶ mbar·L/s, completely eliminating the risk of coolant leakage damaging high-value chips.

(3) Functional Integration: Adapting to the Full-Process Needs of Reliability Testing

Dedicated water-cooled plates are deeply integrated with test fixtures and integrate three core functions: first, the dynamic temperature control system, which precisely adjusts heat dissipation pressure through a lifting module to achieve rapid heating and cooling in temperature cycle tests, with a response speed 3 times faster than traditional schemes; second, the data collaboration function, which has built-in temperature sensors to collect chip temperature data in real time and synchronously upload it to the test platform, providing accurate basis for reliability analysis; third, the anti-interference design, which uses insulating cooling media and electromagnetic shielding coatings to avoid interference with test signals and ensure the accuracy of electrical performance testing.

For long-term reliability testing needs, the water-cooled plate has passed stringent environmental adaptability verification: after 1000 temperature cycles and 10G shock and vibration tests, it still maintains no leakage and no deformation, meeting the long-term use needs of chip test fixtures.

III. Application Scenarios and Core Value: Reliability Assurance Throughout the Entire Chip Testing Process

The application of Liquid cooled plates dedicated to test fixtures runs through the entire process of AI chips from post-packaging verification to mass production sampling inspection, providing customized thermal management solutions for different test scenarios:

(1) Post-Packaging Reliability Testing

In the initial verification stage after 3D packaging is completed, the water-cooled plate provides a stable thermal environment for the chip, supporting key items such as high-temperature aging, temperature cycling, and electrical stress testing. For example, in the 72-hour full-load aging test, its ±0.1℃ temperature control accuracy can ensure stable performance data of the chip under real working conditions, effectively screening out early failure products.

(2) Mass Production Yield Testing

Targeting the high-efficiency detection needs in the mass production stage, the liquid cold plate supports modular test schemes of “1-to-1” or “1-to-multi”, and a single cabinet can meet the test needs of multiple chips at the same time. Its quick adaptation feature enables test fixtures to flexibly switch between different chip models, greatly improving the turnover efficiency of the production line, and is especially suitable for mass production testing scenarios of mainstream AI chips such as NVIDIA GPU GB300 and AMD.

(3) Extreme Performance Verification

In the chip extreme performance test, the water-cooled plate can support a maximum heat dissipation capacity of 3.5kW through pump-driven two-phase phase change technology, meeting the test needs of next-generation ultra-high-power chips such as Rubin Ultra. By precisely controlling the chip temperature, it helps manufacturers determine the extreme operating parameters of the chip and provides data support for product specification definition.

For chip manufacturers, the core value of dedicated liquid cold plate lies not only in improving test efficiency but also in reducing the test misjudgment rate through precise thermal management, increasing mass production yield by 8%-12%, while extending the service life of test fixtures and reducing comprehensive test costs.

IV. Industry Trends and Selection Suggestions: Key Dimensions for Choosing Liquid cold Plates Dedicated to Test Fixtures

With the continuous increase in AI chip power consumption, liquid cold plate dedicated to test fixtures are showing three major development trends: first, accelerated technology integration, with increasingly close software and hardware collaboration with test platforms to achieve integrated control of thermal management and test processes; second, in-depth material innovation, the application of advanced materials such as diamond and liquid metal will further break through the heat dissipation limit; third, intelligent upgrading, optimizing flow channel flow distribution through AI algorithms to achieve dynamic tuning based on real-time chip temperature.

When selecting products, chip manufacturers should focus on three core dimensions: adaptability, which needs to support the mainstream chip package sizes and test fixture interfaces of the enterprise and have quick replacement capabilities; precision, the temperature control accuracy needs to reach ±0.1℃, and the temperature uniformity meets the heat dissipation needs of multi-layer chips in 3D packaging; reliability, which needs to pass industry standards such as IEC FDIS 62368-1 hydrostatic pressure test and ASTM corrosion compatibility test to ensure no leakage risk during long-term use.

Conclusion

Behind the AI chip computing power competition, the technical strength of the reliability verification link directly determines the market competitiveness of products. As a core thermal management equipment, water-cooled plates dedicated to test fixtures solve the thermal concentration problem of 3D packaged chips and the precise temperature control needs in the testing process through structural customization, material process innovation, and function integration, becoming an essential equipment for chip manufacturers from R&D to mass production.

With the continuous iteration of ultra-high-power AI chips, liquid cold plate dedicated to test fixtures will face higher heat dissipation pressure and more stringent test requirements, which not only bring challenges of technological upgrading but also breed broad market opportunities. Choosing a dedicated liquid cold plate with strong adaptability, high precision, and excellent reliability can not only improve chip test efficiency and yield but also help enterprises build core technical barriers in the fierce market competition—this is the core value of Liquid cooled plates dedicated to test fixtures.Our company, KENFA, is capable of designing and providing optimal reliability testing equipment for AI chips. Please feel free to contact us at king@kenfatech.com to discuss this further.