When it comes to high-performance electronics—whether in gaming PCs, data centers, or electric vehicles—efficient heat management is non-negotiable. Excessive heat doesn’t just make your system noisy or uncomfortable to use; it directly affects performance, stability, and the lifespan of your components. The challenge for engineers and PC builders alike is choosing a cooling solution that balances thermal efficiency, cost, space constraints, and long-term reliability. Two leading contenders often come up in this discussion: vapor chamber cooling and liquid cooling. While both aim to remove heat effectively, their working principles, efficiency levels, and best-use scenarios differ significantly.

Vapor chamber cooling uses phase-change technology to rapidly spread heat across a flat surface for efficient dissipation, while liquid cooling relies on circulating fluid to transfer heat to a radiator. The best choice depends on your system’s power density, space constraints, and thermal design goals.

Consider this: A data center hosting hundreds of high-power servers cannot afford even a slight drop in cooling efficiency, as it directly impacts uptime and energy costs. Meanwhile, a gaming enthusiast may prioritize silent operation while pushing their GPU to its limits. Both scenarios demand effective heat solutions—but do they need the same technology?

In this guide, we’ll break down the science behind vapor chambers and liquid cooling, explore their pros and cons, and reveal which option performs better under different conditions. Whether you’re a hardware engineer, a PC builder, or a tech enthusiast planning your next upgrade, this article will help you make an informed decision. Stick around—we’ll also share real-world case studies from industries that have pushed both cooling methods to their limits, showing you where each technology truly shines.

What Is a Vapor Chamber and How Does It Work?

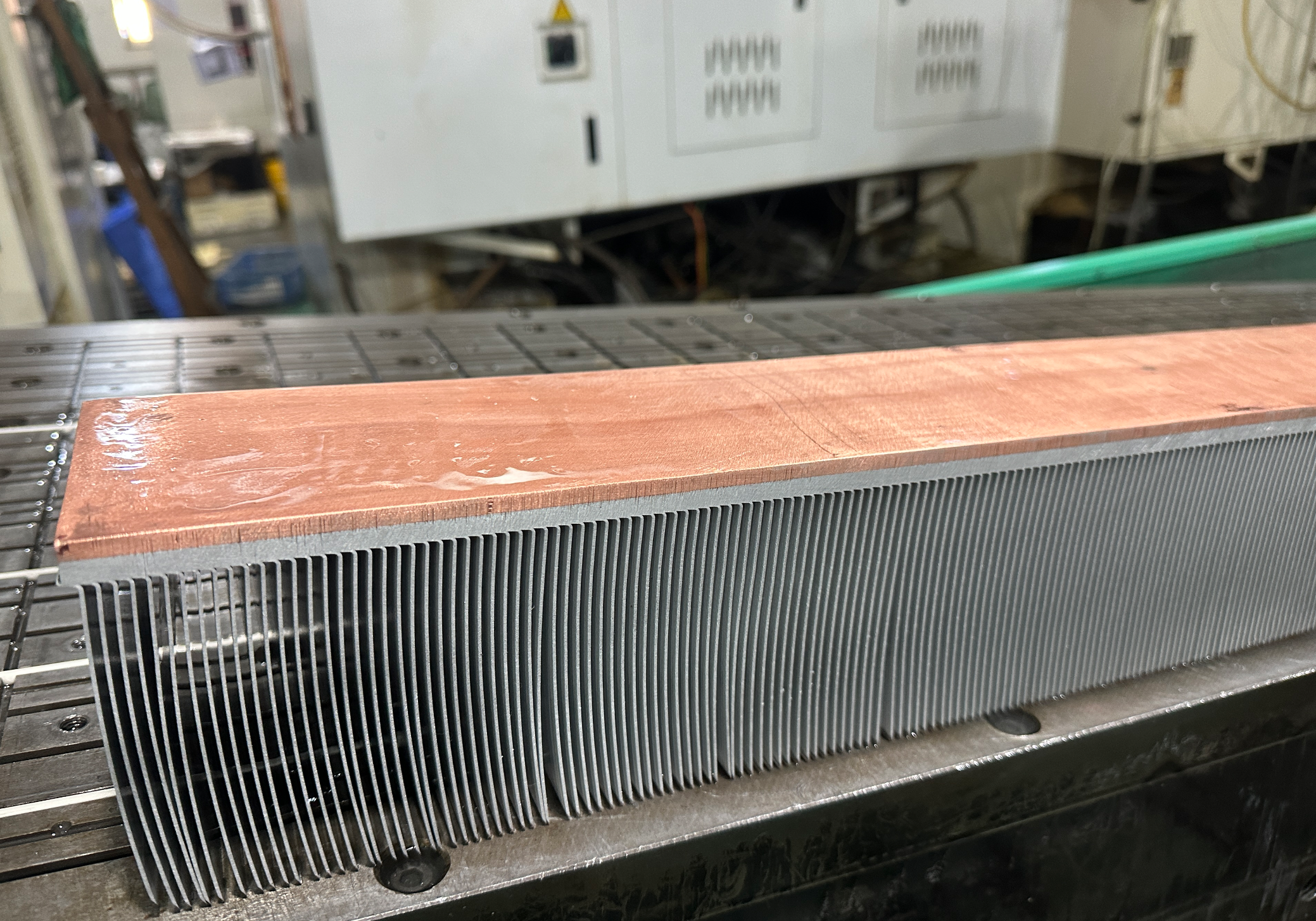

Vapor chamber cooling has become increasingly popular in high-performance electronics due to its ability to efficiently transfer heat from a localized source to a larger surface area. It is often used in modern GPUs, high-density servers, and compact devices where space is limited but heat dissipation is critical.

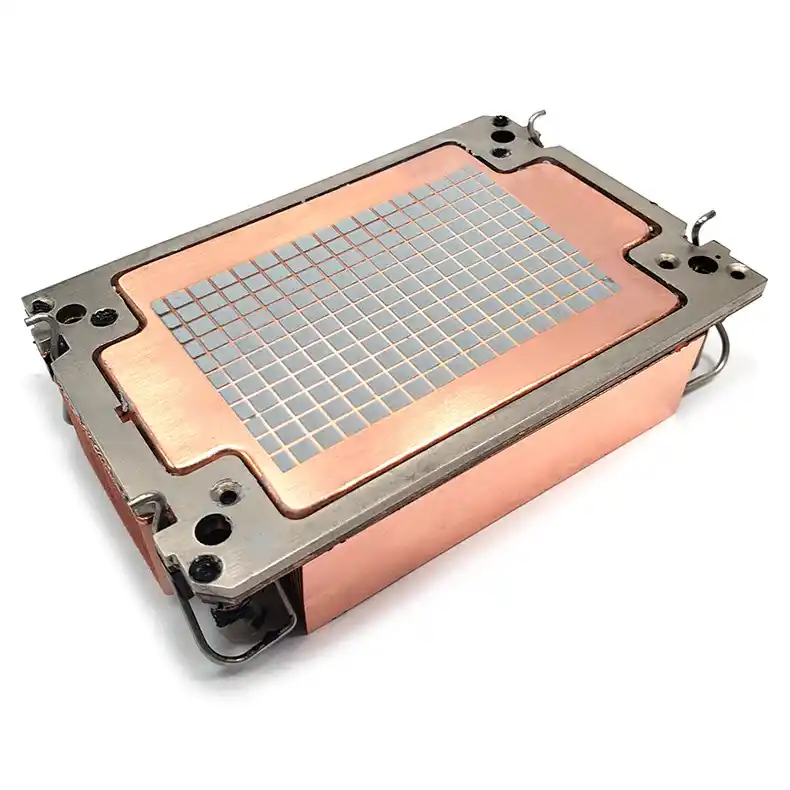

A vapor chamber is a flat, sealed, vacuum-filled metal plate that uses phase-change cooling to rapidly spread heat away from a heat source. It works by converting liquid into vapor, transporting it to cooler regions, and condensing it back into liquid for continuous heat transfer.

Vapor Chamber Defined

A vapor chamber is essentially an advanced heat pipe technology built in a flat, planar form. It is made of highly conductive materials such as copper or aluminum and consists of four main components:

- Metal enclosure: Usually copper for high thermal conductivity.

- Wick structure: A porous layer lining the inner walls that helps return condensed liquid to the heat source.

- Working fluid: Typically water under partial vacuum, allowing phase change at low temperatures.

- Vacuum-sealed chamber: Enables liquid-to-vapor transition efficiently with minimal thermal resistance.

How it works:

- Heat from the component evaporates the working fluid inside the chamber.

- The vapor rapidly spreads across the chamber due to low internal pressure.

- Cooler regions of the plate condense the vapor, releasing latent heat.

- The wick structure passively returns the liquid to the heat source via capillary action.

This closed-loop cycle happens almost instantly, ensuring fast and uniform heat spreading across the chamber surface.

What Are the Advantages of a Vapor Chamber?

Vapor chambers offer several notable benefits compared to traditional cooling methods, making them suitable for high-density thermal applications.

- 1. Exceptional heat spreading: Distributes heat evenly across large surfaces, minimizing hotspots.

- 2. Passive operation: No moving parts, meaning no noise or mechanical failure risk.

- 3. Compact and lightweight: Ideal for slim laptops, GPUs, and small form-factor devices.

- 4. High reliability: Sealed system with long service life, little to no maintenance required.

- 5. Orientation independence: Functions in any position, making it suitable for portable electronics.

💡 Did you know? A well-designed vapor chamber can improve thermal conductivity by over 10x compared to solid copper spreaders, significantly enhancing cooling performance in confined spaces.

What Are the Disadvantages of a Vapor Chamber?

While vapor chambers provide impressive cooling efficiency, they also have some limitations that need to be considered before choosing them for your application:

| Potential Limitation | Impact on Performance or Cost |

|---|---|

| Limited thermal capacity | Performance drops when heat load exceeds design limits (typically <200–300 W for thin chambers). |

| Higher cost | More expensive to manufacture than solid metal heat spreaders or basic heat pipes. |

| Performance loss at high watt densities | Heat flux limits can cause “dry-out,” reducing efficiency in very high-power chips. |

| Integration complexity | Requires precise mounting and good thermal interface materials to perform optimally. |

In short, vapor chambers excel in thin, space-limited environments requiring silent and reliable cooling. However, for extremely high-power systems or cost-sensitive builds, alternative solutions such as advanced liquid cooling may be more appropriate.

Pro Tip: When choosing a vapor chamber, always check its maximum heat flux rating (W/cm²) to ensure it can handle your component’s thermal load effectively.

What Is Liquid Cooling and How Does It Work?

Liquid cooling is a powerful thermal management solution widely used in high-performance PCs, data centers, and industrial electronics. Unlike air cooling, which relies on heatsinks and fans to move hot air away from components, liquid cooling uses a circulating liquid coolant to absorb and dissipate heat more efficiently. This allows for better temperature control, quieter operation, and improved system stability under heavy workloads.

Liquid cooling works by transferring heat from a component (like a CPU or GPU) into a liquid coolant, which is then pumped through tubes to a radiator where fans expel the heat into the air. It provides higher cooling capacity than air solutions, ideal for high-power electronics.

Types of Liquid Cooling: Closed-Loop vs. Custom Loops

There are two primary types of liquid cooling systems, each with different complexity levels, cost, and performance characteristics:

| Cooling Type | Main Components | Typical Use Case |

|---|---|---|

| Closed-Loop (AIO – All-in-One) | Pre-assembled unit with a pump, radiator, and tubing sealed and maintenance-free. | Gamers, professionals, and users wanting plug-and-play liquid cooling without custom assembly. |

| Custom Loop | Separate pump, reservoir, radiator, tubing, water blocks, and fittings assembled manually. | Enthusiasts, overclockers, and high-end workstations requiring maximum cooling performance and aesthetics. |

While AIO coolers are easier to install and require little to no upkeep, custom loops offer greater flexibility and performance at the expense of complexity and cost.

Advantages of Liquid Cooling

Liquid cooling provides multiple benefits over traditional air-based solutions, making it a go-to choice for high-demand computing systems.

- 1. High thermal headroom: Capable of dissipating more heat than standard air coolers, preventing thermal throttling under load.

- 2. Supports overclocking: Lower operating temperatures allow CPUs and GPUs to run at higher frequencies safely.

- 3. Quieter operation: Larger radiators and efficient heat transfer reduce the need for high-speed fans.

- 4. Better heat distribution: Can cool multiple components (CPU, GPU, VRMs) in one loop.

- 5. Aesthetics: Custom loops offer visually appealing builds with clear tubing, colored coolants, and RGB lighting options.

💡 Insight: A high-quality 360mm AIO cooler can handle up to 300–350 W of heat, outperforming most premium air coolers by 15–25°C under full load.

What Are the Disadvantages of Liquid Cooling?

Despite its performance benefits, liquid cooling comes with certain drawbacks that may not make it the best choice for every user:

| Disadvantage | Potential Impact |

|---|---|

| Complex installation | Custom loops require technical knowledge and time to set up correctly. |

| Pump noise and vibration | Even closed-loop coolers can emit a faint buzzing sound from the pump. |

| Risk of leaks | Though rare, leaks can damage sensitive components if not detected early. |

| Maintenance requirements | Custom loops need periodic refilling, cleaning, and checking for wear on tubing and seals. |

| Higher initial cost | Liquid cooling systems cost 30–100% more than comparable air solutions. |

In short, liquid cooling offers superior thermal performance and quiet operation but comes at the expense of cost, complexity, and occasional maintenance. For casual users or those building a budget system, a high-quality air cooler may suffice. But for enthusiasts or industries where performance stability is critical, liquid cooling is often the top choice.

Pro Tip: When choosing liquid cooling, always ensure your case supports the radiator size and that your power supply can handle the additional load from pumps and fans.

Which Cooling Method Is Most Efficient for High-TDP Chips?

As computing power and chip densities increase, managing thermal output becomes critical for stability and performance. Both vapor chamber and liquid cooling technologies aim to handle high Thermal Design Power (TDP) loads effectively, but they excel under different conditions. Choosing the most efficient cooling method depends on factors like heat load, space constraints, noise tolerance, and long-term maintenance requirements.

Liquid cooling generally offers higher raw thermal capacity for extreme TDP chips (200W+), while vapor chambers provide reliable, passive cooling for compact devices and moderate TDP loads with fewer maintenance concerns.

Comparing Cooling Capacity and Heat Transfer Efficiency

Cooling efficiency can be measured by how quickly and effectively a system removes heat from a chip to maintain optimal temperatures under heavy loads. Below is a simplified comparison of vapor chamber and liquid cooling efficiency across different TDP ranges:

| TDP Level | Vapor Chamber Efficiency | Liquid Cooling Efficiency |

|---|---|---|

| ≤100W | Highly efficient, silent, compact | Overkill, higher cost, unnecessary complexity |

| 100–250W | Moderate efficiency, potential heat saturation | High efficiency, stable under sustained load |

| 250W+ | Limited; may struggle to maintain safe temps | Excellent; supports extreme overclocking |

Liquid cooling systems can move more heat away from high-power chips thanks to pumped circulation and larger radiators, while vapor chambers excel in evenly spreading heat but have physical limits on how much they can dissipate.

Is a Vapor Chamber Cooling System Better than Liquid Cooling?

There’s no single winner between vapor chambers and liquid cooling—it depends on your scenario:

- Efficiency: Liquid cooling handles extreme TDP loads more effectively, especially for CPUs and GPUs that sustain over 200W of power draw.

- Reliability: Vapor chambers have no moving parts, making them failure-resistant and maintenance-free compared to pumps and tubing in liquid loops.

- Noise: Vapor chambers are completely silent, while liquid systems rely on fans and pumps, which can add some noise.

- Form Factor: Vapor chambers are slimmer and ideal for laptops, tablets, and compact industrial devices.

💡 Key Insight: For high-end gaming PCs or data centers, liquid cooling usually wins on raw performance. For sealed devices like laptops or EV electronics, vapor chambers shine in reliability and space efficiency.

Noise, Space, and Form Factor Considerations

Beyond cooling power, physical size and noise are important when selecting a thermal solution:

- Small Form Factor Builds: Vapor chambers are ideal for slim designs where bulky radiators don’t fit.

- Silent Systems: Vapor chambers operate silently, while liquid cooling fans can produce 20–35 dB under load.

- Thermal Limits: Liquid cooling scales better for extreme power draw, where fan speed can increase to maintain safe temperatures.

For workstation environments where noise is a key factor, vapor chambers may be preferred despite slightly lower thermal capacity, while gaming rigs or AI computing nodes may benefit from liquid cooling’s headroom.

Cost and Long-Term Maintenance Trade-Offs

Cost and maintenance often tip the scales for many buyers:

- Upfront Cost: Vapor chambers are generally cheaper for low-to-mid TDP setups, while high-end liquid cooling systems can cost 50–150% more.

- Maintenance: Vapor chambers are sealed and require zero maintenance over years of use.

- Long-Term Risk: Liquid loops may face pump failure or leaks after prolonged operation, potentially requiring part replacement.

Pro Tip: For mission-critical applications where downtime is unacceptable, vapor chambers are a safer long-term bet. For users prioritizing maximum performance headroom, a quality liquid cooling setup remains unmatched.

Ultimately, the “most efficient” cooling solution depends on balancing thermal needs, device size, cost, and long-term reliability. High-TDP desktop and server chips tend to favor liquid cooling, while vapor chambers dominate in mobile and embedded designs.

How Do Hybrid Solutions Compare?

Hybrid cooling solutions blend the strengths of both vapor chambers and liquid cooling systems to deliver superior thermal performance, especially in high-density, high-power environments. By combining these technologies, manufacturers can overcome the individual limitations of each method. But are hybrid solutions always worth the added cost and complexity?

Hybrid cooling systems offer the best of both worlds—high thermal capacity and efficient heat spreading—making them ideal for laptops, servers, and data centers. However, they come with added complexity, cost, and maintenance requirements.

Vapor Chambers + Heat Pipes

One common hybrid design involves pairing vapor chambers with heat pipes, creating a multi-stage heat transfer system. Here’s how it works:

- Vapor Chamber: Sits directly on the chip, rapidly spreading heat over a large surface area.

- Heat Pipes: Transfer the spread-out heat to fin stacks or secondary heat exchangers for dissipation.

This approach is widely used in:

- High-Performance Laptops: Keeps CPUs and GPUs cooler in thin chassis designs where airflow is limited.

- High-Density Servers: Handles multiple high-TDP chips in close proximity, reducing thermal throttling.

✅ Benefit: Improved heat distribution and removal without the bulk of full liquid cooling setups, ideal for compact devices.

⚠️ Drawback: Increased manufacturing complexity and cost compared to standalone solutions.

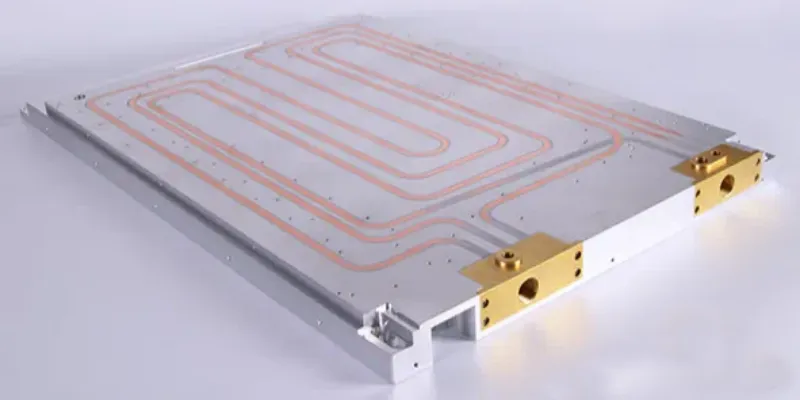

Full Liquid + Vapor Spreaders

In larger-scale applications, such as data centers or custom HPC builds, hybrid systems integrate liquid cooling with vapor spreaders:

- Vapor Spreaders: Absorb and distribute heat evenly across the base plate.

- Liquid Loops: Actively transport heat away to radiators or chillers for final dissipation.

These setups are especially beneficial for:

- Cloud Servers: Where hundreds of processors operate simultaneously under heavy load.

- Overclocked Workstations: Custom PC builds that push hardware to maximum limits.

Example: Some leading data center solutions report up to 30–40% improved thermal efficiency compared to standard liquid loops when a vapor spreader stage is included before coolant transfer.

Are Hybrid Systems Worth It?

Deciding whether a hybrid solution is worth the investment depends on several factors:

- Performance Needs: Critical for environments where standard vapor chambers or liquid cooling alone cannot keep temperatures below thermal limits.

- Space Constraints: Hybrid designs often fit better than full custom loops in slim or high-density setups.

- Budget & Complexity: Hybrids are more expensive and involve multiple components that may require servicing over time.

💡 Key Takeaway: Hybrid cooling is often overkill for mainstream gaming PCs but can be a game-changer for enterprise servers, EV battery systems, and next-gen laptops where every degree of temperature reduction matters.

For mission-critical projects, consulting with an advanced thermal solutions provider like KenFa Tech can help design a tailored hybrid cooling system that balances performance, cost, and reliability.

How to Choose Between Vapor Chamber and Liquid Cooling for Your Project?

Selecting the right cooling solution is crucial for maintaining performance, prolonging hardware life, and ensuring energy efficiency. Both vapor chambers and liquid cooling have unique advantages and drawbacks, making the choice highly dependent on your specific application and project goals.

Choose vapor chambers for compact, reliable, and low-maintenance cooling needs. Opt for liquid cooling for high-TDP, overclocked, or multi-chip systems requiring maximum thermal capacity.

Use Case Scenarios

Different projects benefit from different cooling technologies:

- Gaming Rigs: Liquid cooling is ideal for high-end CPUs/GPUs under heavy loads and overclocking. Vapor chambers excel in smaller, quieter builds.

- Data Centers: Hybrid liquid + vapor solutions handle massive heat loads while maintaining rack density and uptime.

- Telecom Racks: Vapor chambers efficiently manage thermal hotspots in limited airflow environments.

- EV Battery Systems: Liquid cold plates outperform in high-energy, high-temperature electric vehicle power packs where active cooling is vital.

Decision Criteria: TDP, Space, Noise, Reliability, Cost

When deciding between the two solutions, consider the following:

| Criteria | Vapor Chamber | Liquid Cooling |

|---|---|---|

| TDP Support | Moderate (up to ~200W per unit) | High (>300W+, scalable) |

| Space Efficiency | Very compact, thin profile | Requires pumps, tubes, radiators |

| Noise | Passive, silent operation | Fans & pumps produce noise |

| Reliability | Low maintenance, fewer moving parts | Risk of leaks, periodic maintenance needed |

| Cost | Moderate to high (custom sizes costlier) | Higher initial investment, especially for custom loops |

💡 Tip: Match your system’s TDP and space limitations first, then consider noise and cost trade-offs.

Questions to Ask Your Thermal Partner (e.g., KenFa Tech)

Before committing to a cooling method, you should ask:

- Which solution is optimal for my system’s TDP and heat flux density?

- What are the estimated long-term operating costs and maintenance needs?

- Can you provide thermal simulations (e.g., Ansys Icepak, Flotherm) before production?

- What customization options exist for my industry (EV, telecom, HPC)?

- Can you design hybrid solutions for better balance of performance and space usage?

Having these discussions early ensures a solution tailored to your project—not a one-size-fits-all approach.

Conclusion & Call to Action

Choosing between vapor chamber and liquid cooling depends on multiple factors: thermal power needs, available space, noise requirements, and long-term reliability. Vapor chambers shine in compact, silent builds, while liquid cooling dominates in high-TDP and multi-chip scenarios. Hybrid solutions offer a middle ground for enterprise or specialized applications.

✅ Key Takeaway: The “best” cooling solution is project-specific. There’s no universal winner—only what fits your system’s power, budget, and operational demands best.

At KenFa Tech, we specialize in custom thermal management solutions, from high-performance vapor chambers to liquid cold plates and hybrid systems. Our engineers leverage advanced simulations and rapid prototyping to design cooling solutions that maximize efficiency and reliability for your specific application.

📩 Ready to optimize your cooling strategy? Contact KenFa Tech today to discuss your project requirements and receive a tailored thermal solution that ensures peak performance and long-term stability.