Have you ever noticed how hot your phone or laptop gets when you’re gaming or streaming? Now, try to imagine a building packed with thousands of super-powered computers. These machines are running the artificial intelligence and complex calculations that shape our world. The heat they produce is incredible. For a long time, we’ve fought this heat with what are basically huge air conditioning systems. But as our technology gets smarter and faster, that old method is reaching its limit. We’re facing a thermal wall that could slow down innovation.

A Direct Liquid Cooling (DLC) system is a highly targeted thermal solution that brings liquid coolant into direct contact with the hottest electronic components. It uses custom-designed cold plates mounted on processors (CPUs, GPUs) to absorb heat efficiently. The liquid then circulates, carrying the heat away to be cooled remotely. This process is far more effective than air cooling, enabling greater computing density, massive energy savings, and higher performance for demanding workloads like AI.

This isn’t just a minor upgrade; it’s a fundamental shift in how we manage heat. Think of it like this: air cooling is like trying to cool down on a hot day by standing in front of a fan. DLC is like jumping into a cool swimming pool. The difference in efficiency is massive. As processors become more powerful, they generate more heat than air can physically remove. This challenge has created a bottleneck. But what if we could deliver precise, powerful cooling right where it’s needed most?

That’s the promise of Direct Liquid Cooling. In this complete guide, we will break down everything you need to know about DLC. We’ll explore its inner workings, compare it to other methods, cover its real-world benefits, and look at what it takes to implement it. Let’s dive in and see how this technology is paving the way for the future of computing.

Understanding Direct Liquid Cooling: Definition and Fundamentals

Direct Liquid Cooling (DLC) is a technology that uses a liquid coolant to cool electronic components through direct contact. It mounts specially designed “cold plates” on top of hot processors (like CPUs and GPUs) to absorb their heat far more efficiently than air ever could. This method is fundamental for managing the intense heat from modern, high-power electronics, making it essential for AI data centers, HPC, and other demanding applications where peak performance is non-negotiable.

What Exactly Is Direct Liquid Cooling?

Let’s break it down with a simple analogy. Imagine you have a tiny, powerful car engine that gets incredibly hot. Instead of just pointing a fan at it (like air cooling), what if you attached a small, hollow metal block directly to its hottest part and ran cool water through it? The water would absorb the heat instantly and carry it away, keeping the engine at a perfect temperature. That’s precisely what Direct Liquid Cooling does for a computer chip.

In a DLC system, that “hollow metal block” is a highly engineered cold plate. It’s designed to sit right on top of a CPU or GPU, providing a direct path for heat to escape.

But how is this different from other liquid cooling approaches?

- Indirect Liquid Cooling: This method uses liquid to cool the *air* inside a server cabinet, and that air then cools the components. It’s an improvement over traditional AC, but less efficient than DLC because heat has to travel through the air first.

- Immersion Cooling: This involves completely submerging entire servers in a bath of non-conductive fluid. While extremely effective, it can be complex, costly, and messy to service the hardware.

DLC offers the power of liquid with surgical precision, targeting only the components that need it most.

Key Principles of Heat Transfer in DLC

DLC is so effective because it leverages two fundamental principles of heat transfer: conduction and convection.

- Conduction: This is heat transfer through direct touch. The processor gets hot, and because the cold plate is physically touching it, the thermal energy conducts directly from the chip into the metal of the cold plate.

- Convection: This is heat transfer through the movement of a fluid. As the liquid coolant flows through tiny channels inside the cold plate, it absorbs the heat from the metal and carries it away from the processor.

A crucial element that perfects this process is the Thermal Interface Material (TIM). This is a special thermal paste or pad applied between the chip and the cold plate. It fills in microscopic air gaps that would otherwise trap heat, ensuring a seamless and highly efficient conductive path.

Why DLC for AI Data Centers?

The short answer is power and heat density. The processors that power artificial intelligence are true workhorses, and that work generates an immense amount of heat in a very small area. Every processor has a rating called Thermal Design Power (TDP), which is a measure of the maximum heat it generates.

A typical office computer’s CPU might have a TDP of 65-120 watts. In contrast, a single high-end AI GPU can easily exceed 700 watts. Trying to cool a 700-watt chip with air is like trying to put out a bonfire with a handheld fan. Air simply isn’t dense enough to remove that much concentrated heat fast enough, leading to performance throttling or even hardware failure.

DLC is the solution. It provides the high-performance cooling needed to keep these powerful processors running at their full potential, making it a foundational technology for the future of AI.

How Does Direct Liquid Cooling Work?

A Direct Liquid Cooling system operates much like the cooling system in your car. A pump circulates liquid coolant through a closed loop of tubes. This liquid flows to cold plates mounted on hot components, where it absorbs heat. It then carries this heat away to a heat exchanger to be cooled down before repeating the cycle. This continuous process efficiently removes thermal energy, keeping vital electronics performing at their best under heavy loads.

Step-by-Step Process of DLC Operation

While DLC systems can be complex, the core process is straightforward. Think of it as a journey that heat takes to leave the processor. Here’s a breakdown of the key steps in a typical DLC loop:

- Coolant Circulation: It all starts with a pump. This device pushes the liquid coolant through the system, creating a steady flow.

- Distribution: The coolant travels from the pump to a manifold. A manifold is like a splitter; it divides the main stream of coolant into smaller tubes that lead to each individual server or component.

- Heat Absorption: These tubes connect to the cold plates mounted directly on the CPUs and GPUs. As the cool liquid flows through micro-channels inside the plates, it absorbs the intense heat generated by the processors via conduction.

- Heat Transport: Now carrying the heat, the warmed liquid flows out of the cold plates and back into another manifold, which collects it into a single stream.

- Heat Rejection: The hot coolant is piped to a heat exchanger. Here, the heat is transferred from the coolant to another medium, usually facility water or air. The now-chilled coolant is ready to start its journey all over again.

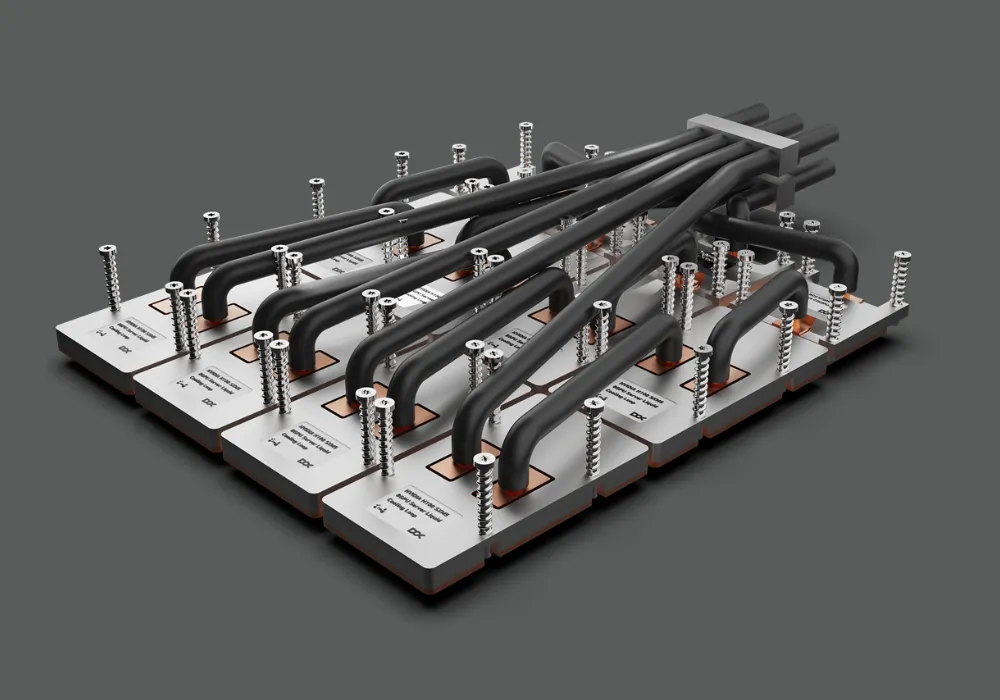

This entire process is managed by a **Coolant Distribution Unit (CDU)**. The CDU is the brain and heart of the operation, containing the pumps, heat exchangers, and control systems needed to keep everything running smoothly and safely.

Single-Phase vs. Two-Phase DLC Systems

Not all DLC systems are the same. They primarily fall into two categories based on how the coolant behaves.

- Single-Phase DLC: This is the most common type. The coolant, typically a water-glycol mixture, always stays in a liquid state. It absorbs heat, its temperature rises, and it flows away to be cooled. It’s reliable, proven, and easier to implement.

- Two-Phase DLC: This advanced method uses special dielectric fluids with low boiling points. When the fluid hits the hot cold plate, it boils and turns into a vapor (gas). This phase change absorbs a massive amount of heat—much more than just raising the liquid’s temperature. The vapor then travels to a condenser, where it cools back down into a liquid, releasing the heat.

The magic of two-phase cooling is in the state change. Just like how boiling water absorbs a lot of energy to become steam, the coolant absorbs huge thermal loads as it turns to vapor, making it incredibly efficient for cooling the hottest, most powerful chips.

System Architecture and Integration

DLC systems are designed to be flexible and can be integrated at different scales within a data center.

- In-Rack Setups: A self-contained CDU is installed within or attached to a single server rack. This is a great solution for adding liquid cooling to specific high-density racks without changing the whole facility.

- In-Row Setups: A larger CDU is placed between a row of server racks, servicing the entire row. This balances efficiency and scalability for larger deployments.

- Facility-Level Setups: In the largest data centers, the DLC system can be connected directly to the building’s main water cooling infrastructure. This is the most efficient and scalable architecture for massive HPC or AI clusters.

These architectures often use two separate loops: a primary loop with treated coolant that goes to the servers, and a secondary loop that uses facility water to cool the primary loop’s heat exchanger. This two-loop design prevents any facility water from ever reaching the sensitive IT equipment.

Components of a Direct Liquid Cooling System

A Direct Liquid Cooling system is built from several key parts working together. The core hardware includes custom cold plates that absorb heat, pumps that circulate fluid, and heat exchangers that get rid of the heat. The system also relies on specialized coolants and smart monitoring systems. These components ensure the safe and efficient removal of massive heat loads from high-performance electronics, making the entire operation reliable and effective.

Core Hardware Elements

At its heart, a DLC system is a collection of specialized hardware designed for one purpose: moving heat. Each component plays a vital role in this process.

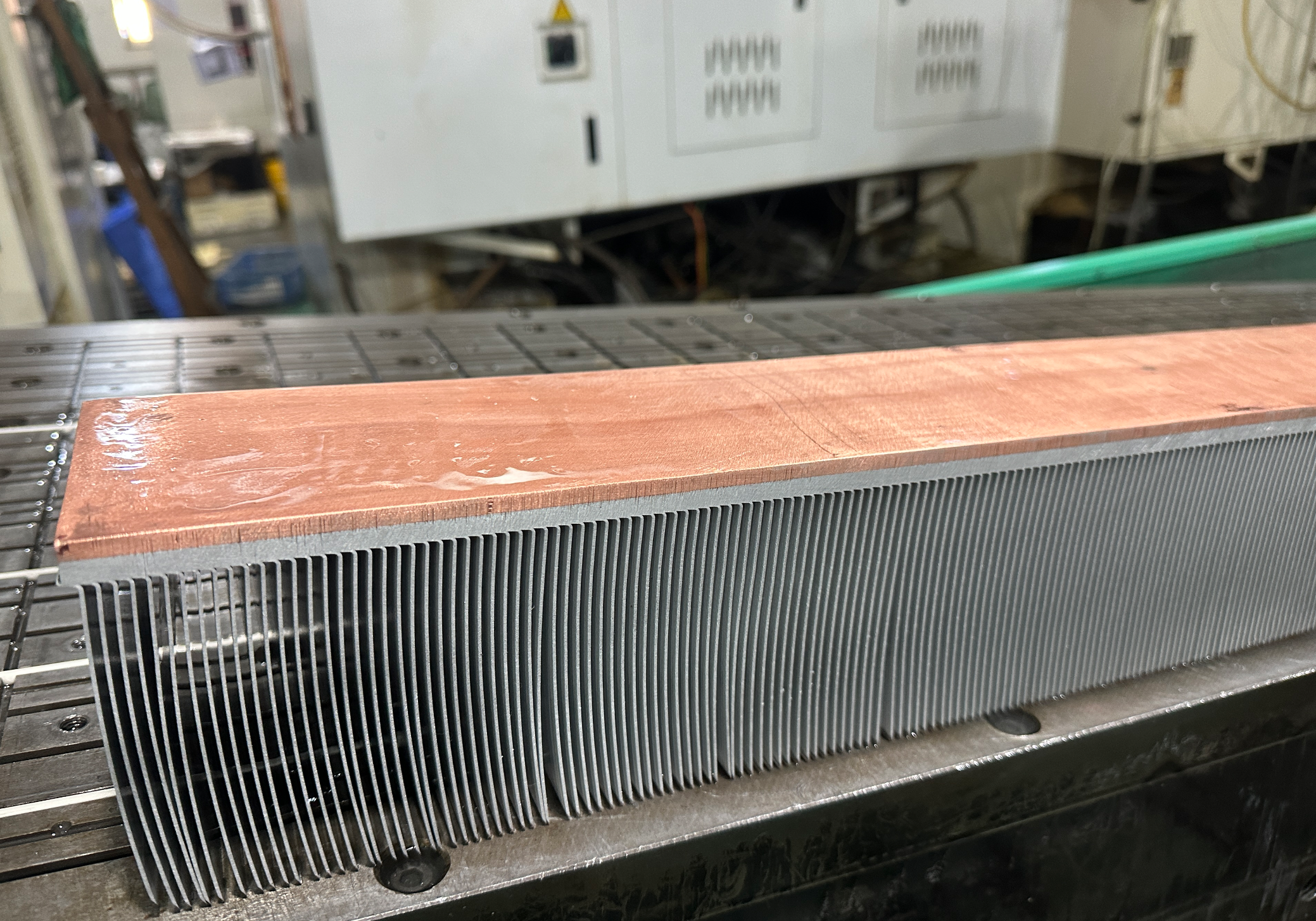

- Cold Plates: These are the stars of the show. A cold plate is a sealed metal block, usually made of copper or aluminum, with intricate channels carved inside. It sits directly on a hot processor. Coolant flows through these channels, pulling heat away from the chip with incredible efficiency.

- Pumps: The pump is the engine of the DLC system. It provides the force needed to circulate the coolant through the entire loop, ensuring a constant flow to and from the hot components.

- Heat Exchangers: Once the coolant has absorbed heat, it needs a place to dump it. The heat exchanger is that place. It transfers the thermal energy from the hot coolant into a secondary loop, which is often facility water or outside air.

- Reservoirs: A reservoir holds extra coolant. It helps to handle any fluid expansion or contraction due to temperature changes and makes it easier to fill or drain the system during maintenance.

Coolants and Fluids Used in DLC

The liquid itself is a critical part of the system. The choice of coolant depends on the specific application, performance needs, and budget. There are two main categories:

Water-based coolants are the most common choice. They are excellent at transferring heat and are cost-effective. Usually, they are mixed with glycol and other additives to prevent corrosion and biological growth. However, they are electrically conductive, so leaks are a serious concern. Dielectric fluids, on the other hand, do not conduct electricity. This makes them much safer for use around electronics. They are essential for two-phase systems and mission-critical applications where leaks cannot be tolerated.

Monitoring and Control Systems

You can’t just set up a DLC system and walk away. Modern systems include sophisticated monitoring and control technology to ensure everything runs perfectly and safely. These are the brains behind the brawn.

- Sensors: Tiny sensors are placed throughout the loop to monitor temperature, pressure, and flow rates in real-time.

- Leak Detection: This is a crucial safety feature. Systems include sensors that can detect even the smallest drop of liquid, allowing the system to shut down and alert operators before any damage occurs.

- Automation Software: Smart software controls the pump speeds and coolant flow automatically. It can ramp up cooling during heavy workloads and scale it back to save energy when demand is low, optimizing performance and efficiency.

Benefits and Advantages of Direct Liquid Cooling

Adopting Direct Liquid Cooling brings huge benefits that go far beyond just keeping things cool. DLC unlocks major gains in energy efficiency, boosts computing performance, and leads to significant cost savings over time. It allows data centers to become more powerful and sustainable. This makes it a smart investment for any organization that relies on high-performance computing to stay competitive and grow.

Energy Efficiency and Sustainability

One of the biggest wins with DLC is a massive drop in energy consumption. Traditional air cooling systems are energy hogs, using huge fans and chillers. Because liquid transfers heat so much better than air, DLC systems need far less power to do the same job.

- Improved PUE: Data centers measure efficiency with a metric called Power Usage Effectiveness (PUE). A perfect score is 1.0. Air-cooled data centers often have a PUE of 1.6 or higher, meaning a lot of energy is wasted on cooling. DLC can lower that PUE to 1.1 or even less, resulting in huge energy savings.

- Reduced Carbon Footprint: Less energy use means a smaller environmental impact. By cutting electricity demand, data centers can significantly reduce their carbon footprint.

Performance Enhancements

DLC doesn’t just save energy; it unleashes the true potential of your hardware.

- Higher Density Deployments: With superior cooling, you can pack more servers into a single rack without worrying about overheating. This allows you to increase your computing power without needing more floor space.

- Reduced Noise: DLC systems eliminate the need for dozens of loud, high-speed server fans. This creates a much quieter and safer working environment for technicians.

- Extended Hardware Lifespan: Electronics last longer when they run at stable, cool temperatures. DLC prevents extreme temperature swings that can degrade components over time, protecting your investment.

Cost Savings Over Time

While Direct Liquid Cooling can have a higher initial cost (CAPEX) than traditional air cooling, the long-term savings on operational expenses (OPEX) are substantial. The dramatic reduction in electricity bills often provides a rapid return on investment, making it a financially smart move for large-scale operations.

Five Reasons DLC Outperforms Immersion Cooling

While both are liquid cooling methods, DLC often has practical advantages over full immersion cooling.

- Targeted Cooling: DLC focuses cooling on the hottest components, like the CPU and GPU. It doesn’t waste energy cooling parts that don’t need it.

- Easier Maintenance: Servicing a server in a DLC system is clean and simple. With immersion, technicians have to pull a dripping server out of a tank of fluid.

- Better Compatibility: DLC solutions are designed to fit into standard server racks and chassis, making it easier to retrofit existing data centers.

- Greater Scalability: You can start with DLC in just one or two high-power racks and expand as needed. Immersion often requires a larger, all-or-nothing commitment.

- Enhanced Safety: DLC systems use a minimal amount of fluid within a closed loop. Advanced leak detection makes them extremely reliable.

Direct Liquid Cooling vs. Other Cooling Methods

Choosing the right cooling strategy is a critical decision. Direct Liquid Cooling stands out, but how does it really stack up against other common methods? Each approach has its own strengths and weaknesses. Understanding these differences is key to selecting the best solution for a specific need, whether you’re building a new AI cluster or upgrading an existing data center. Let’s compare them side-by-side.

DLC vs. Traditional Air Cooling

This is the most fundamental comparison. Air cooling uses fans to blow air across heat sinks. It’s a simple and familiar technology, but it’s no match for DLC when it comes to high-power electronics. The reason is simple physics: water can absorb and transfer heat over 1,000 times more effectively than air by volume.

This thermal superiority leads to huge efficiency gains. DLC systems can use warmer facility water (around 32°C or 90°F) for cooling, which drastically reduces the need for expensive, power-hungry chillers. Air cooling, in contrast, requires frigid air to be effective, wasting enormous amounts of energy.

| Feature | Direct Liquid Cooling (DLC) | Traditional Air Cooling |

|---|---|---|

| Heat Removal Capacity | Very High | Low to Moderate |

| Energy Efficiency (PUE) | Excellent (as low as 1.1) | Poor (often 1.6+) |

| Server Density | Very High | Limited by heat |

DLC vs. Immersion Cooling

Immersion cooling, where entire servers are submerged in dielectric fluid, is extremely powerful. However, it comes with significant practical challenges. DLC offers a more balanced and often more practical approach.

The key difference is precision versus submersion. DLC targets the hot spots with surgical accuracy, while immersion floods everything. This makes DLC much easier to integrate into existing data centers and far simpler to service.

Handling servers that have been dunked in a tank of fluid is complex and messy. Retrofitting a facility for large immersion tanks is also a major construction project. DLC, by contrast, works with standard server racks and hardware, making it a much more flexible and scalable solution.

DLC vs. Hybrid and Indirect Systems

Hybrid and indirect liquid cooling systems offer a middle ground. For example, an indirect system might use liquid to cool the door of a server rack, which then cools the air inside. These solutions can be an improvement over pure air cooling, but they still rely on air as the final step to cool the components, creating an efficiency bottleneck.

When should you choose each?

- Choose DLC for the highest-density racks, AI/HPC workloads, and maximum energy efficiency.

- Choose Indirect/Hybrid systems when you want a moderate efficiency boost without modifying the servers themselves.

- Choose Air Cooling only for low-density workloads where performance and efficiency are not top priorities.

Implementation Considerations for Direct Liquid Cooling

Switching to Direct Liquid Cooling is a big step. It requires careful planning to be successful. You need to think about your current data center layout, the installation process, and long-term maintenance. Getting these details right from the start ensures a smooth transition and helps you get the most value from your investment. A well-planned deployment will deliver all the benefits of DLC without unexpected surprises.

Planning and Design Factors

Before you buy any hardware, you need a solid plan. The first step is to look at your existing space. Is there room for CDUs and the necessary piping? You must also consider the layout of your server racks. For older data centers, a key question is retrofit compatibility. Can your current servers be easily fitted with cold plates? Working with an experienced partner can help you answer these questions and design a system that fits your specific environment perfectly.

Infrastructure and Installation Challenges

Choosing the right vendor is the most critical decision you’ll make. A good partner will not just sell you equipment; they will guide you through the entire process, from initial design to final installation, ensuring the project stays on time and on budget.

The installation itself can be a challenge. It involves plumbing, electrical work, and careful integration with your IT hardware. This process requires specialized skills. It’s important to factor in the installation costs and timelines when planning your budget. A phased rollout, where you upgrade a few racks at a time, can often make the process more manageable.

Maintenance, Safety, and Best Practices

Modern DLC systems are designed to be safe and low-maintenance, but they aren’t “set it and forget it.”

- Leak Prevention: This is the top priority. High-quality components and professional installation are essential. Built-in leak detection sensors provide an immediate alert if anything goes wrong.

- Regular Upkeep: You’ll need to check coolant levels, inspect for wear and tear, and ensure the pumps are running correctly. This is usually part of a simple annual maintenance schedule.

- Regulatory Compliance: Make sure your system meets all local building and safety codes.

Metrics for Evaluating DLC Efficiency

How do you know if your DLC project is a success? You need to track the right metrics. Start by measuring your PUE before and after the installation. You should also calculate the total heat removal capacity of the new system and track your energy usage. Over time, these numbers will allow you to calculate your total return on investment (ROI) and prove the value of your upgrade.

Future Trends and Innovations in Direct Liquid Cooling

Direct Liquid Cooling is just getting started. The technology is evolving quickly, driven by the non-stop demand for more computing power. The future of DLC is not just about being stronger; it’s about being smarter, more adaptable, and even more sustainable. We are heading towards a future where high-performance cooling is seamlessly integrated into every powerful system, from massive data centers to small devices at the edge of the network.

Here are some of the key innovations shaping the future:

- Advanced Coolants: Researchers are developing new biodegradable and more efficient fluids. These next-generation coolants will offer even better performance while being safer for the environment.

- AI-Optimized Systems: Future DLC systems will use artificial intelligence to manage themselves. They will predict thermal loads and adjust pump speeds and coolant flow in real-time, squeezing out every last drop of efficiency.

- Integration with Edge Computing: As more processing happens outside the data center, we will see compact, rugged DLC solutions designed for edge servers. This will bring high-performance computing to remote and challenging environments.

As AI and other intensive workloads become standard, the adoption of DLC will accelerate dramatically. It is expected to become the default cooling solution for all high-density computing within the next decade, playing a vital role in data center sustainability.

Frequently Asked Questions (FAQs)

What is the difference between direct liquid cooling and immersion cooling?

Direct Liquid Cooling (DLC) uses cold plates to cool specific components, like CPUs and GPUs. Immersion cooling submerges the entire server in a tank of non-conductive fluid. The key difference is precision (DLC) versus total submersion (immersion), which makes DLC easier to service and retrofit.

How does direct liquid cooling impact energy consumption in data centers?

DLC drastically reduces energy consumption. By eliminating the need for most large server fans and energy-intensive air chillers, it can lower a data center’s Power Usage Effectiveness (PUE) from 1.6 or higher down to as low as 1.1, resulting in significant electricity savings.

What are the main disadvantages of direct liquid cooling?

The primary disadvantages are a higher initial investment (CAPEX) compared to air cooling and increased complexity. A DLC system requires careful planning, professional installation, and introduces plumbing into the data center, which requires robust safety protocols like leak detection.

Can direct liquid cooling be retrofitted into existing air-cooled data centers?

Yes, one of the major advantages of DLC is its suitability for retrofitting. Because it works with standard server racks, it can be deployed incrementally, allowing a data center to upgrade specific high-density racks without overhauling the entire facility’s cooling infrastructure.

Is direct liquid cooling suitable for all types of servers and workloads?

While it can be used for any server, DLC provides the most benefit for high-density servers with powerful, high-TDP components, such as AI training clusters and HPC systems. For low-power servers or storage arrays, traditional air cooling is often still sufficient and more cost-effective.

What coolants are commonly used in direct liquid cooling systems?

The most common coolants are water-based mixtures (often with glycol for anti-corrosion/anti-freeze properties) and engineered dielectric fluids. Water-based solutions offer excellent thermal performance, while dielectric fluids are non-conductive, providing an extra layer of safety.

Let’s Build the Future of Cooling, Together

The message is clear: as computing demands grow, Direct Liquid Cooling is no longer a niche technology—it’s an essential upgrade. We’ve seen how it tames the intense heat of AI and HPC, slashing energy costs, boosting performance, and paving the way for a more sustainable digital future. It’s the key to unlocking the full potential of your hardware and staying ahead of the curve.

But implementing the right solution requires expertise. Every workload is different, and every data center has unique challenges. A one-size-fits-all approach won’t deliver the results you need. That’s where a true partner comes in.

Are you ready to move beyond the limits of air cooling? If you’re looking to enhance performance, improve efficiency, and future-proof your infrastructure, the team at KenfaTech is here to help. We specialize in designing and manufacturing custom thermal solutions, from high-performance liquid cold plates to complete DLC systems tailored to your exact specifications.

Don’t let heat become your bottleneck. Reach out to KenfaTech today to start a conversation with our thermal experts. Let’s work together to design a custom cooling solution that meets your challenges and drives your innovation forward. Your journey to a cooler, more efficient future starts with a single inquiry.