In fields such as aerospace thermal control, high-performance computing, and new energy, efficient heat transfer and precise temperature control have always been core technical requirements. Traditional single-phase fluid cooling systems are limited by the bottleneck of sensible heat transfer and are difficult to meet the heat dissipation needs of high-power density equipment. As an efficient heat transfer technology based on the latent heat of working fluid phase change, the Mechanically Pumped Two-Phase Loop (MPTL) has gradually become a core solution in the field of high-end thermal management due to its excellent heat transfer performance and temperature control accuracy. This paper will comprehensively and in-depth analyze the MPTL from the aspects of definition, working principle, core characteristics, application fields, existing shortcomings, and future improvement directions.The design principle of MPTL occupies a very important position in the field of thermal management.

I. What is a Mechanically Pumped Two-Phase Loop (MPTL)?

A Mechanically Pumped Two-Phase Loop (MPTL) is a closed-loop heat transfer system that uses a mechanical pump as the power source and relies on the evaporation-condensation phase change process of a working fluid (such as ammonia, R-123, water, etc.) for heat transfer. Its core logic is to achieve efficient heat transfer and precise control through the large amount of latent heat absorbed or released during the phase change of the working fluid. Different from single-phase fluid loops that only transfer heat through temperature changes (sensible heat) of the working fluid, the heat transfer efficiency of MPTL can be improved by more than an order of magnitude under the same volume and mass.In essence, MPTL is a complex system that deeply integrates mechanical drive, phase change heat transfer, fluid control and other technologies. Its core goal is to solve high-power, long-distance, and high-precision thermal management problems, and it is especially suitable for special scenarios with strict requirements on weight, volume, and temperature control accuracy (such as space environments, high-end electronic equipment, etc.). Compared with passive two-phase heat transfer systems (such as heat pipe and loop heat pipes), MPTL actively drives the circulation of working fluid through a mechanical pump, which breaks away from gravity dependence, can flexibly adapt to different installation attitudes and heat transfer distances, and has stronger controllability.

II. Working Principle of Mechanically Pumped Two-Phase Loops

The working process of MPTL revolves around the “liquid-gas-liquid” phase change cycle of the working fluid. The entire system is composed of core components such as a pump set, evaporator, condenser, reservoir, pipeline, and control components. Each component cooperates to complete the absorption, transmission, and release of heat. The specific working principle can be divided into the following four key steps:

1. Working Fluid Supply and Drive

The liquid working fluid stored in the reservoir enters the liquid supply pipeline at a certain pressure and flow rate under the active drive of the mechanical pump and flows to the evaporator. As the “power heart” of the system, the mechanical pump’s core function is to overcome pipeline resistance, evaporator resistance, and condenser resistance to ensure the continuous and stable flow of the working fluid in the closed loop. At the same time, the flow rate of the working fluid can be flexibly controlled by adjusting the pump speed or displacement to adapt to different heat load requirements.

2. Heat Absorption and Phase Change Evaporation

After the liquid working fluid enters the evaporator, it is in close contact with the evaporator wall (the evaporator is usually directly attached to the heat source, such as the core components of aerospace remote sensors, chips, etc.). The heat generated by the heat source is transferred to the evaporator wall through thermal conduction and then absorbed by the liquid working fluid. When the heat absorbed by the working fluid reaches its saturated evaporation latent heat, a phase change occurs, converting from liquid to a gas-liquid mixture (some working fluid is completely evaporated into gas). During this process, the temperature of the working fluid remains basically constant (equal to the saturation temperature), but it can absorb a large amount of heat, achieving efficient heat absorption.

3. Gas-Liquid Transmission and Condensation Heat Release

Under the continuous drive of the mechanical pump, the gas-liquid mixture (or gaseous working fluid) at the outlet of the evaporator flows to the condenser through the return pipeline. As a heat release component, the outside of the condenser is usually in contact with a low-temperature environment (such as space, cooling water tank, etc.). The gas-liquid mixture releases phase change latent heat in the condenser, and the gaseous working fluid is gradually condensed into liquid. The heat is then transferred to the external environment through the condenser, completing the heat transfer.

4. Working Fluid Return and Cycle Closure

The liquid working fluid at the outlet of the condenser flows back into the reservoir. The reservoir not only stores the working fluid but also buffers the volume change caused by the phase change of the working fluid (the volume of gaseous working fluid is much larger than that of liquid working fluid). At the same time, it can separate the incompletely condensed gaseous working fluid to ensure that the working fluid flowing into the mechanical pump is mainly liquid, avoiding cavitation damage to the pump body. Subsequently, the liquid working fluid is sucked into the mechanical pump again and driven to circulate, completing the entire heat transfer closed loop.

Throughout the working process, the phase change of the working fluid is the core, and the efficient use of latent heat is the key to MPTL’s heat transfer efficiency far exceeding that of single-phase systems; the active drive of the mechanical pump ensures the flexibility and stability of the system, enabling it to adapt to complex operating conditions.

III. Core Characteristics of Mechanically Pumped Two-Phase Loops

As a high-end thermal management technology, the core characteristics of MPTL are concentrated in heat transfer efficiency, temperature control accuracy, adaptability, etc., and it also has certain technical thresholds. Specifically, it can be summarized into the following advantages and characteristics:

1. Extremely High Heat Transfer Efficiency and Strong Heat Load Bearing Capacity

The latent heat of phase change of the working fluid is much larger than the sensible heat (for example, the evaporation latent heat of water under standard atmospheric pressure is about 2260 kJ/kg, while the specific heat capacity of water is only 4.2 kJ/(kg·K). The heat absorbed by the evaporation of the same mass of water is 5.4 times that absorbed by heating up 100℃). Therefore, under the same working fluid flow rate and volume, MPTL can transfer much more heat than single-phase fluid loops, and can easily meet the heat dissipation needs of high-power density equipment (such as heat dissipation of chip hotspots above 300 W/cm²).

2. High Temperature Control Accuracy and Good Temperature Stability

The temperature of the working fluid remains constant during the phase change (equal to the saturation temperature under the corresponding pressure). By adjusting the system pressure (or working fluid flow rate), the working temperature of the evaporator and condenser can be precisely controlled. The temperature control accuracy can usually reach ±0.5 K ~ ±2 K, which is far better than that of single-phase fluid loops (the temperature control accuracy is generally above ±5 K). This excellent temperature control performance is crucial for temperature-sensitive equipment (such as aerospace cameras, high-precision sensors, laser devices, etc.).

3. Long Heat Transfer Distance, Strong Adaptability, and No Gravity Dependence

The active drive of the mechanical pump enables the working fluid to overcome long-distance pipeline resistance and gravity effects. The heat transfer distance can reach tens of meters or even hundreds of meters (for example, the heat bus system on satellites has a heat transfer distance of more than 20 meters), and it can flexibly adapt to any installation attitude (horizontal, vertical, inclined, etc.). It is suitable for both space microgravity environments and complex ground operating conditions (such as large data centers, on-board electronic equipment, etc.). In contrast, passive two-phase heat transfer systems (such as heat pipes) are greatly affected by gravity, and their heat transfer distance and installation attitude are limited.

4. Compact System and Light Weight

Due to its high heat transfer efficiency, MPTL requires much smaller working fluid volume and pipeline diameter than single-phase fluid loops, which can effectively reduce the system volume and weight. In the aerospace field, reducing each 1 kg of weight can bring significant savings in launch costs, so MPTL has become the preferred solution for spacecraft thermal control systems.

5. Strong Controllability and Flexible Adaptability to Variable Load Conditions

By adjusting the mechanical pump speed, valve opening, etc., it can quickly respond to changes in heat load (such as equipment switching from standby state to full-load operation), and real-time adjust the working fluid flow rate and system pressure to ensure that the system can operate stably under different heat loads and avoid overheating or supercooling.

IV. Main Application Fields of Mechanically Pumped Two-Phase Loops

With its excellent heat transfer performance and temperature control accuracy, MPTL has been widely used in high-end fields such as aerospace, high-performance computing, new energy, and national defense, and has become a core technology to solve complex thermal management problems. The specific application scenarios are as follows:

1. Aerospace Field (Core Application Scenario)

In aerospace missions, spacecraft (satellites, spaceships, deep space probes, etc.) are in vacuum, microgravity, and extreme temperature environments, and the thermal management of core electronic equipment (such as remote sensors, processors, communication modules) is extremely difficult. As the “heat bus” of spacecraft, MPTL can realize centralized heat collection, long-distance transmission, and efficient heat dissipation, and is a key system to ensure the normal operation of spacecraft.

Typical application cases include: the lightweight pumped fluid loop “heat bus” carried by the Chang’e-5 probe, which realizes high-precision temperature control of core detection equipment; the ammonia working fluid MPTL system developed by Thales Alenia Space of France for the SES-17 geostationary satellite, which successfully achieves heat dissipation of 200 devices with a total power of 6 kW; the thermal control system of the instrument compartment of NASA’s James Webb Space Telescope also adopts MPTL technology to ensure the stable operation of the instrument in an extremely low-temperature environment.

2. High-Performance Computing and Data Center Field

With the development of artificial intelligence and big data technology, the power density of server chips in data centers continues to increase (the power of mainstream server chips has now reached more than 300 W, and some high-end chips even exceed 500 W). Traditional air cooling and single-phase liquid cooling technologies are no longer able to meet the heat dissipation needs. Based on the advantage of phase change heat transfer, MPTL can realize efficient heat dissipation of chip hotspots and reduce the energy consumption of the cooling system (energy consumption can be reduced by more than 30% compared with air cooling systems).

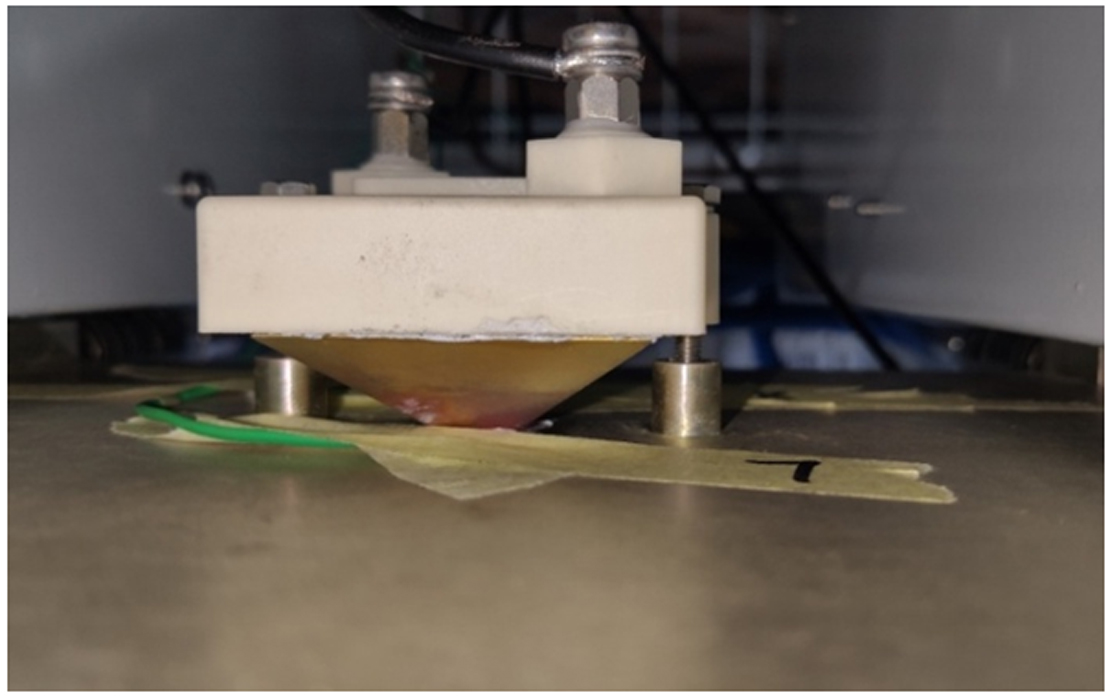

Typical application cases: Tests by Nokia Bell Labs show that the MPTL system using a two-phase microchannel evaporator can control the thermal resistance below 0.013 K/W for ultra-high hotspots of 314 W/cm², and the heat dissipation performance is far better than that of single-phase liquid cooling systems (the thermal resistance of single-phase liquid cooling is usually above 0.05 K/W); some domestic supercomputing centers have begun to pilot MPTL cooling technology to solve the heat dissipation problems of high-end GPUs and CPUs.

3. New Energy and Power Electronics Field

In equipment such as new energy vehicles, photovoltaic inverters, and wind power converters, the power density of power semiconductor devices (such as IGBTs, SiC chips) is constantly increasing. Excessively high operating temperatures will seriously affect the service life and reliability of the devices. MPTL can realize precise temperature control of power semiconductor devices, ensure the stable operation of equipment in high-temperature environments, and reduce the volume of the cooling system to adapt to complex scenarios such as on-board and outdoor use.

For example, after adopting MPTL cooling technology, the on-board charger (OBC) and motor controller of new energy vehicles can control the operating temperature of the devices below 80℃. Compared with traditional air cooling systems, the heat dissipation efficiency is improved by more than 50%, and the weight of the cooling system is reduced by 30%.

4. National Defense and High-End Equipment Field

In national defense equipment such as radars, laser weapons, and high-precision guidance equipment, core components (such as radar transmitters, laser generators) generate a lot of heat, and have strict requirements on temperature stability and system compactness. MPTL can meet the efficient heat dissipation and precise temperature control needs of these equipment, and improve the operational performance and reliability of the equipment. For example, after adopting MPTL cooling technology, the transmitting module of the shipborne phased array radar can realize continuous high-power operation and avoid performance degradation caused by overheating.

5. Medical and High-End Instrument Field

In medical and scientific research instruments such as nuclear magnetic resonance (MRI), electron microscopes, and high-precision spectrometers, some core components (such as superconducting magnets, detectors) need to work at a constant temperature. MPTL can provide high-precision temperature control to ensure the measurement accuracy and stability of the instruments. For example, the magnet of superconducting MRI needs to work at liquid helium temperature, and MPTL can be used as an auxiliary cooling system to realize efficient heat dissipation and reduce liquid helium consumption.

V. Existing Shortcomings and Technical Challenges of Mechanically Pumped Two-Phase Loops

Although MPTL has many advantages, as a complex phase change heat transfer system, it still faces many technical challenges and shortcomings in the process of design, manufacture, and operation, which limit its application in a wider range of fields. The specific aspects are as follows:

1. Prominent Two-Phase Flow Stability Problems (Core Challenge)

The flow state of gas-liquid two phases in pipelines and components is complex (such as bubbly flow, slug flow, annular flow, etc.), and flow instability is prone to occur, especially in microgravity environments or variable load conditions, the problem is more serious. For example, “superheating” may occur when the system starts, and the outlet temperature of the evaporator may be 7-8 K higher than the temperature control point instantaneously; during operation, problems such as uneven gas-liquid separation, local dry-out (dry spots) of the evaporator, and excessive pressure fluctuations may occur, which may lead to system shutdown or equipment damage in severe cases.

2. Reliability and Adaptability Challenges of Mechanical Pumps

The mechanical pump is the core power component of MPTL, and its reliability directly determines the service life and stability of the system. In extreme operating conditions such as space, high temperature, and high pressure, the pump body has prominent problems such as sealing performance, wear, and cavitation: cavitation will cause pump body vibration, increased noise, and even damage the impeller; wear after long-term operation will reduce the efficiency and flow stability of the pump. In addition, how to design micro-pumps suitable for two-phase working fluids (especially in the aerospace field with strict requirements on weight and volume) is also one of the technical difficulties.

3. Difficulties in System Integration and Lightweight Design

MPTL is composed of multiple components (pump, evaporator, condenser, reservoir, valve, sensor, etc.). The matching between components, pipeline layout optimization, and system sealing performance (preventing working fluid leakage) put forward extremely high requirements for integrated design. Especially in the aerospace field, the limitations on system weight and volume are more stringent. How to realize lightweight and compact integration on the premise of ensuring performance is an important technical challenge.

4. Working Fluid Selection and Compatibility Issues

The performance of the working fluid directly affects the heat transfer efficiency, operating temperature range, and reliability of MPTL. An ideal working fluid should have the characteristics of large latent heat of phase change, large specific heat capacity, suitable saturation temperature, good chemical stability, non-toxicity, and harmlessness. However, there is currently no perfect working fluid: ammonia has large latent heat and good refrigeration effect, but it is toxic and corrosive; water has large latent heat and is environmentally friendly, but its saturation pressure changes greatly with temperature, and its applicability is poor under low-temperature conditions; Freon-based working fluids (such as R-123) have good stability, but some models have destructive effects on the ozone layer and have been restricted from use. In addition, the compatibility between the working fluid and system materials (such as pipelines, seals) (preventing corrosion and swelling) also needs to be strictly controlled.

5. Immature Intelligent Diagnosis and Adaptive Control Technology

The operating state of MPTL is affected by many factors such as heat load, ambient temperature, and working fluid flow rate. The flow state and temperature change are complex and difficult to monitor in real time and accurately. At present, the intelligent diagnosis technology for problems such as system flow instability, local dry-out, and pump body failure is not mature, and the adaptive control ability is weak. It is difficult to achieve fully automatic and stable operation under complex operating conditions, and it needs to rely on manual intervention or simple feedback control, which limits the reliability and applicability of the system.

6. High Cost and Low Industrialization Level

The core components of MPTL (such as micro mechanical pumps, microchannel evaporators, high-precision sensors) have complex manufacturing processes and high requirements on materials and processing accuracy, resulting in high system costs (currently, the cost of a set of aerospace-grade MPTL system can reach several million yuan, and the cost of ground-level systems is also much higher than that of single-phase liquid cooling systems). In addition, the industrialization level of related technologies is low, and there is a lack of standardized components and design specifications, which limits its wide application in the civilian field.

VI. Future Improvement Directions and Development Trends of Mechanically Pumped Two-Phase Loops

In response to the existing technical challenges of MPTL and combined with the development needs of fields such as aerospace, electronics, and new energy, the future improvement directions of MPTL will focus on stability improvement, lightweight integration, intelligent control, cost reduction, etc. At the same time, it will expand to more efficient, reliable, and extensive application scenarios. The specific development trends are as follows:

1. Optimize Two-Phase Flow Design and Improve System Stability

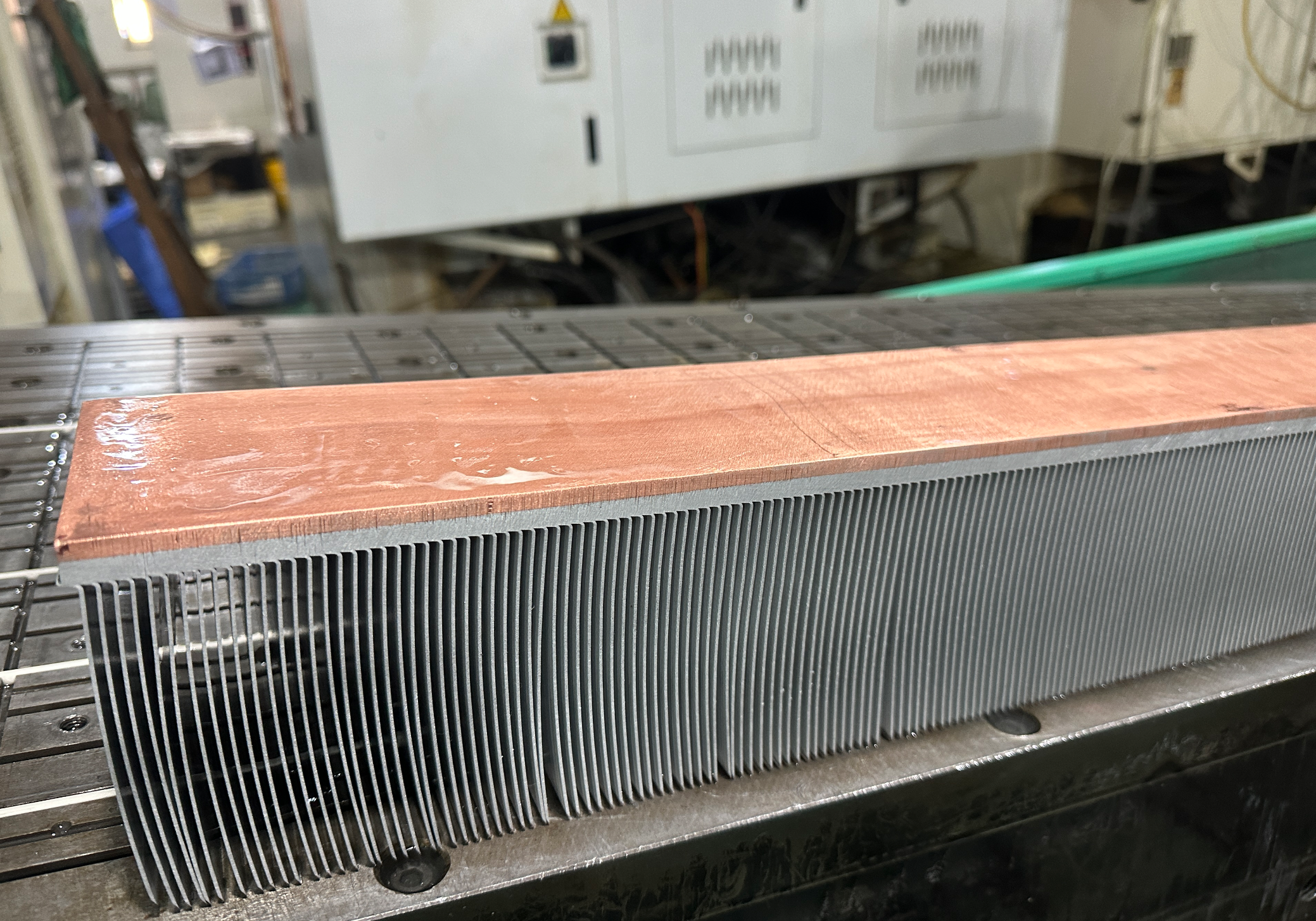

Through numerical simulation (such as CFD simulation) and experimental testing, in-depth study the flow characteristics of two-phase flow under complex conditions such as microgravity and variable load, optimize the structural design of evaporators and condensers (such as adopting microchannel, porous media and other structures), improve gas-liquid separation and flow state, and suppress problems such as flow instability and local dry-out. For example, setting microchannel arrays in the evaporator can enhance the wettability of the working fluid and reduce the generation of dry spots; setting gas-liquid separators in the pipeline can improve the phase separation efficiency of the working fluid and ensure the stable operation of the pump body.

2. Develop High-Performance and High-Reliability Core Components

To address the reliability issues of mechanical pumps, develop miniaturized, oil-free, and long-life pump bodies (such as magnetic drive pumps, piezoelectric pumps, electromagnetic pumps, etc.), improve the sealing performance, cavitation resistance, and wear resistance of the pump body, and extend the system service life (the service life target of aerospace-grade systems can reach more than 10 years). At the same time, optimize the manufacturing processes of evaporators and condensers (such as 3D printing, microfabrication technology) to improve heat transfer efficiency and structural compactness, and realize lightweight integration.

3. Develop Environmentally Friendly and Efficient New Working Fluids

Focusing on the two core needs of environmental protection and high efficiency, develop new working fluids: on the one hand, optimize the formula of existing working fluids (such as mixed working fluids) to balance performance such as latent heat, saturation temperature, and compatibility; on the other hand, develop non-toxic, harmless, and ozone layer-friendly environmental working fluids (such as new hydrofluoroolefins, natural working fluid mixtures, etc.) to replace traditional harmful working fluids. At the same time, strengthen the research on the compatibility between working fluids and system materials to improve system reliability.

4. Introduce Intelligent Control and Diagnosis Technology to Realize Adaptive Operation

Combine the Internet of Things, artificial intelligence, and sensor technology to build an intelligent monitoring and control system for MPTL: arrange high-precision sensors (temperature, pressure, flow rate, phase fraction sensors) at key parts of the system (evaporator outlet, pump inlet, condenser inlet, etc.) to collect operating data in real time; establish prediction models for two-phase flow state and fault diagnosis based on machine learning algorithms to realize early warning of problems such as flow instability, local dry-out, and pump body failure; develop adaptive control strategies to automatically adjust parameters such as pump speed and valve opening according to changes in heat load and environment to ensure the stable operation of the system under complex working conditions.

5. Promote Standardization and Industrialization to Reduce System Costs

Formulate standardized design specifications and testing standards for MPTL core components (pumps, evaporators, condensers, etc.), promote the mass production of components, and reduce manufacturing costs. At the same time, strengthen industry-university-research cooperation, transform aerospace-grade technology to the civilian field (such as data centers, new energy vehicles, medical instruments, etc.), expand the application scale, further reduce costs through large-scale production, and promote the industrialization development of MPTL technology.

6. Expand Multi-Scenario Applications and Integrate Emerging Technologies

In the future, MPTL will further expand application scenarios, such as deep-sea equipment (thermal control systems of deep-sea probes), aerospace (thermal protection systems of hypersonic vehicles), extreme environment equipment (thermal control systems of polar scientific research equipment), etc. At the same time, it will be deeply integrated with emerging technologies (such as superconducting technology, quantum computing, nuclear fusion devices) to solve high-end thermal management problems in these fields. For example, the core chips of quantum computers need to work in extremely low-temperature environments, and MPTL can be used as an auxiliary cooling system to realize efficient heat dissipation; the first wall components of nuclear fusion devices generate a lot of heat, and MPTL can realize high-power density heat dissipation to ensure the stable operation of the device.

VII. Conclusion

As an efficient heat transfer technology based on the latent heat of phase change, the Mechanically Pumped Two-Phase Loop has shown irreplaceable value in high-end fields such as aerospace and high-performance computing due to its advantages of high heat transfer efficiency, precise temperature control, and strong adaptability. Although it still faces technical challenges such as two-phase flow stability, component reliability, and high cost, with the continuous progress of design optimization, core component research and development, and intelligent control technology, the performance of MPTL will continue to improve, the cost will gradually decrease, and the application scenarios will continue to expand.

In the future, the Mechanically Pumped Two-Phase Loop will develop in the direction of “more efficient, more reliable, more intelligent, and more economical”. It will not only provide better thermal management solutions for high-end fields such as aerospace and national defense but also gradually enter the civilian field, empower the development of industries such as data centers, new energy vehicles, and medical instruments, and become a core force driving the progress of high-end thermal management technology.KENFA TECH is a professional thermal management company that provides customers with customized design and production of heat sinks and liquid cooling plates, meeting the demand for stable and reliable operation of customers’ thermal management products. For any requirements, please feel free to send us an email for discussion and mutual learning.