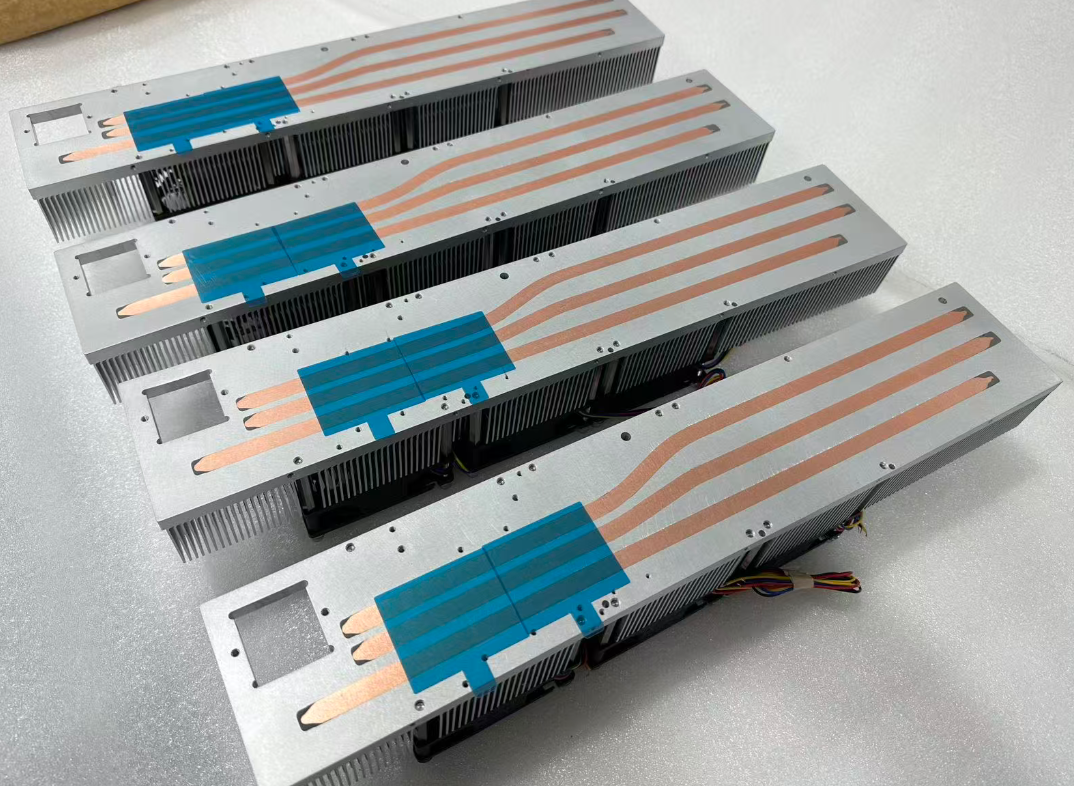

SURFACE COATING: SURTEC 650 treatment refers to a type of surface coating treatment process that uses Surtec 650 passivation solution. Surtec 650 is a trivalent chromium passivation solution for aluminum and aluminum alloys, and can also be used for conversion coating of magnesium alloys. Apart from its practical application being of great significance, the surface treatment method of the heat sink is also very important.The following is a detailed introduction to it:

Key Features

Excellent Corrosion Resistance: The passivation film formed by Surtec 650 has outstanding corrosion resistance, which can effectively prevent metals from contacting the external environment and thus play a role in corrosion prevention. According to the neutral salt spray test standards of ASTM B-117 and DIN 50021 SS, metals treated with Surtec 650 start to show initial white rust only after more than 336 hours. Its corrosion resistance is comparable to that of hexavalent chromium passivation processes.

Low Contact Resistance: The coating has extremely low contact resistance (less than 0.8 mohm/cm²), which gives it great advantages in the electronics industry and enables it to meet the conductivity requirements of electronic components.

High Temperature Resistance: The Surtec 650 coating can resist high temperatures up to 100°C without reducing its corrosion protection ability, and has good thermal stability.

Environmental Protection and Safety: Surtec 650 contains no hexavalent chromium, which complies with environmental regulations such as RoHS and REACh. It is non-toxic, safe to operate, and the wastewater treatment is relatively simple.

Application Scope

Surtec 650 is applicable to various industries such as aerospace, automotive, electronics, and construction. For example, in the aerospace industry, it can be used as a passivation treatment for aluminum and magnesium alloy components, replacing traditional cadmium coatings and hexavalent chromium passivation processes; in the electronics industry, it can be used for the surface treatment of aluminum electronic enclosures to ensure good conductivity and corrosion resistance; in the automotive industry, it can be used for the surface treatment of automotive parts to improve their corrosion resistance and paint adhesion.

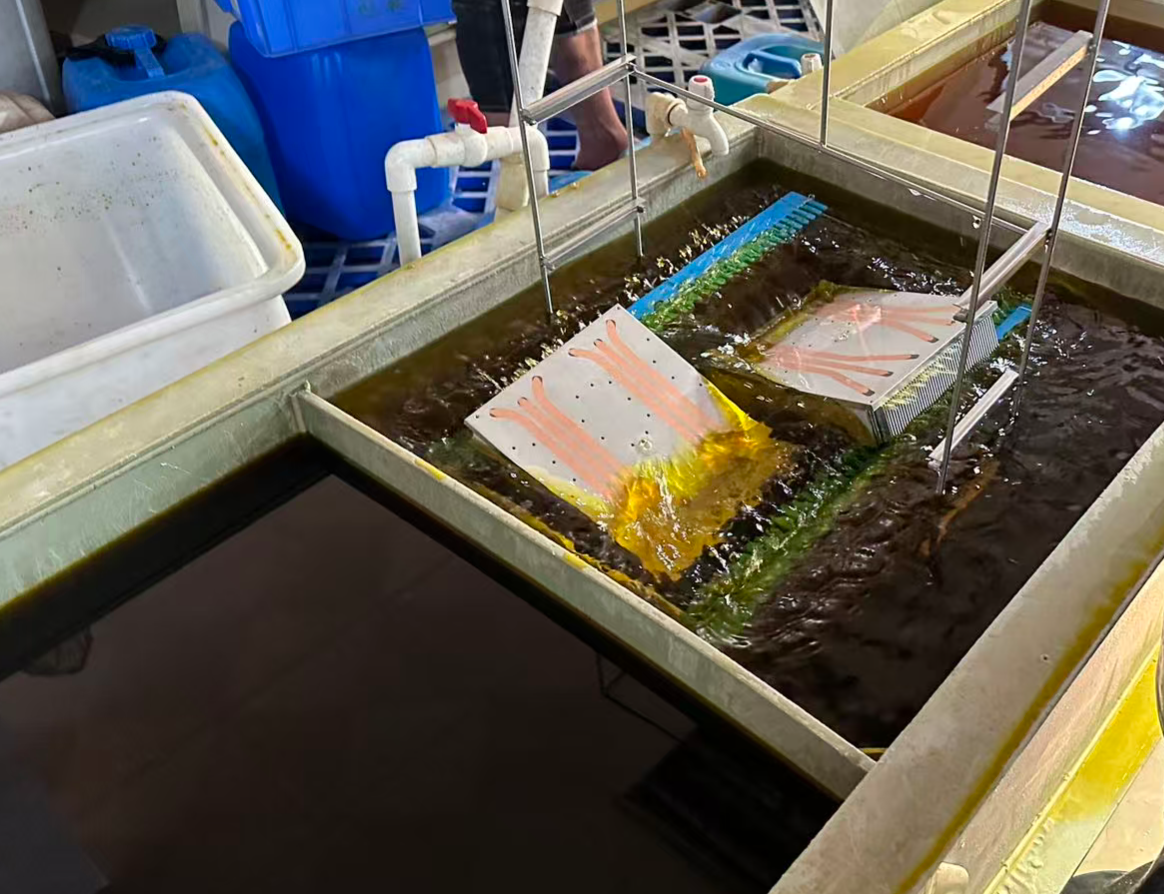

Treatment Process

Surtec 650 is easy to operate in immersion, spray, and manual wiping processes. Generally, deionized water is used to dilute the Surtec 650 concentrate to an appropriate concentration, with the temperature controlled between 30-40°C and the pH value between 3.8-4.0. The treatment time varies depending on specific process requirements and materials, usually 1-4 minutes when used as pre-treatment for coating, and 2-6 minutes when used as corrosion resistance treatment.

Appearance Effect

After treatment with Surtec 650, a transparent, light-colored coating will be formed on the metal surface, showing an iridescent luster ranging from blue to tan. This appearance effect is not only aesthetically pleasing but also can be used as an intuitive criterion to judge whether the coating is uniform and complete. The core of aluminum heat sink passivation is “thorough cleaning, uniform film formation, and complete residue removal” — the degreasing and pickling in the pre – treatment determine the “cleanliness” of the surface, the passivation step determines the “compactness” of the film, and the rinsing and drying in the post – treatment determine the “stability” of the film. The chemical concentrations, temperatures, and times vary for different passivation processes (such as chromium – free passivation), but the general step framework can refer to the above process. The specific parameters need to be adjusted according to the chemical instructions and the requirements of the workpieces.This surface treatment is also applicable to the heat pipe heat sink with nickel-tin solder paste welding,skived fin heat sink. However, the final process must apply a layer of anti-oxidation sealing agent film to the heat pipe.