Driven by the wave of digitalization, the popularization of 5G communication networks is accelerating, and the research and development of 6G technology is advancing continuously. As the core hub of information transmission, communication base stations have witnessed a significant increase in deployment density and operational load. The continuous improvement in the integration of base station equipment has led to a surge in the number of internal heating elements, with the power of a single sector reaching several kilowatts, far exceeding that of 4G base stations. More importantly, most base stations are deployed in complex outdoor environments and must withstand harsh conditions such as high temperatures, sand and dust, wind and rain. To ensure the stable operation of equipment, a sealed structural design must be adopted, which makes it difficult for heat in the internal cavity to be dissipated through natural convection, forming the core contradiction between “sealing and heat dissipation”. The quality of the thermal management system directly determines the stability of base station signal transmission, equipment service life and operation and maintenance costs, and has become a key technical link in the construction of communication infrastructure.

I. Core Pain Points of Thermal Management in Communication Base Stations and Traditional Solutions

(I) Core Pain Point: The Dilemma of Heat Accumulation in Sealed Environments

Although the sealed design of communication base stations (usually meeting IP65/IP67 protection level requirements) can effectively block the intrusion of external impurities such as dust and water vapor and protect internal core components (such as chips, power modules, filters, etc.), it also completely cuts off air circulation between the inside and the outside. During the operation of the base station, a large amount of heat generated by heating elements continuously accumulates in the closed cavity. If it cannot be exported in a timely manner, the temperature of the cavity will continue to rise, leading to a series of problems: first, unstable signal transmission, such as call drops, data transmission delays or errors; second, accelerated aging of components, a significant increase in failure rate, shortened equipment service life and increased maintenance costs; third, in extreme cases, it may cause equipment burnout, resulting in regional communication interruptions and serious economic losses and social impacts. Therefore, achieving efficient heat dissipation without damaging the sealed structure is the core goal of base station thermal management design.

(II) Traditional Solution: Application and Limitations of Die-Casting Process + Fin Cooling

To meet the heat dissipation needs of sealed base stations, the traditional solution in the industry is mainly “die-casting process + back fin cooling”. Relying on mature technology and controllable costs, this solution has been widely used in 4G and early 5G base stations. Its core principle is to use the excellent thermal conductivity of aluminum alloy materials and the integrated molding advantage of die-casting process to achieve the dual functions of structural protection and basic heat dissipation.

Specifically, this solution usually adopts aluminum alloy die-castings as the base station shell or core heat dissipation carrier. Aluminum alloy has low density (about 2.7g/cm³) and good thermal conductivity. Through the die-casting process, the integrated molding of the shell and heat dissipation fins can be realized, reducing assembly links. It not only improves structural sealing and stability, but also increases the heat dissipation area through fins, conducts the heat in the internal cavity to the fin surface, and then diffuses it into the air through natural convection or passive heat dissipation. For example, the shell of some base station AAUs (Active Antenna Units) adopts an integrated die-casting process, reducing the number of parts from 12 to 1, improving assembly efficiency by 50%, while ensuring good heat dissipation effect and air tightness.

However, with the continuous improvement of the power density of 5G base stations, the limitations of the traditional die-casting fin heat dissipation solution have gradually become prominent: first, limited heat dissipation efficiency. The thermal conductivity of aluminum alloy is usually between 130-175W/m·K. For high heat flux density scenarios, the heat conduction speed is difficult to match the heat generation rate, which is prone to local hotspots; second, single heat conduction path. Heat can only be conducted to the fins through the shell. Due to structural limitations, it is difficult to quickly export the heat deep in the cavity; third, passive heat dissipation relies on ambient wind speed. Under extreme working conditions such as high temperature and no wind, the heat dissipation effect is greatly reduced, which cannot meet the long-term stable operation needs of the base station. Therefore, developing a more efficient and flexible heat dissipation structure has become the key to solving the thermal management problem of high-power density base stations.

II. Innovative Solution: Design of T-Shaped Heat Pipe Embedded High-Efficiency Heat Dissipation Structure

To break through the bottleneck of traditional heat dissipation solutions, this paper proposes an innovative design of “aluminum plate embedded heat pipes + T-shaped structure heat dissipation”. Through the efficient phase change heat transfer characteristics of heat pipes and optimized structural layout, it realizes the rapid export and efficient dissipation of heat inside the sealed base station, meeting the heat dissipation needs of high-power density scenarios. The core idea of this solution is: using an aluminum plate as the heat conduction carrier, constructing an efficient heat path by embedding heat pipes on the upper and lower surfaces of the aluminum plate, quickly converging the heat scattered in various areas of the aluminum plate to one end, then integrating a heat sink at this end, and dissipating the heat through forced convection. The overall structure is similar to a “T-shape”, taking into account the full-process efficiency of heat collection, conduction and dissipation.

(I) Core Components and Structural Design

The T-shaped heat dissipation structure is mainly composed of three core parts, and each component works synergistically to form a complete thermal management closed loop:

-

Aluminum Plate Carrier: A high thermal conductivity aluminum alloy plate (such as 6063 aluminum alloy with a thermal conductivity of about 201W/m·K) is selected as the basic carrier. Its surface is closely attached to the heating elements inside the base station and is responsible for collecting heat generated by each heating point. The thickness and size of the aluminum plate can be flexibly designed according to the internal space of the base station and the layout of heating elements to ensure good contact with heating elements and uniform heat conduction.

-

Embedded Heat Pipes: As the core heat conduction component, copper vacuum heat pipes are selected, filled with pure water or ethanol as the working fluid, and a copper powder sintered wick is arranged on the inner side of the pipe wall. The heat pipes are embedded into the reserved channels on the upper and lower surfaces of the aluminum plate through the embedding process. The channels are closely attached to the heat pipes (the gap can be filled with thermal conductive silicone to reduce contact thermal resistance), ensuring that the heat collected by the aluminum plate can be quickly transferred to the heat pipes. The number and arrangement of heat pipes can be adjusted according to the heat generation power, usually evenly arranged along the heat conduction direction to achieve rapid convergence of scattered heat.

-

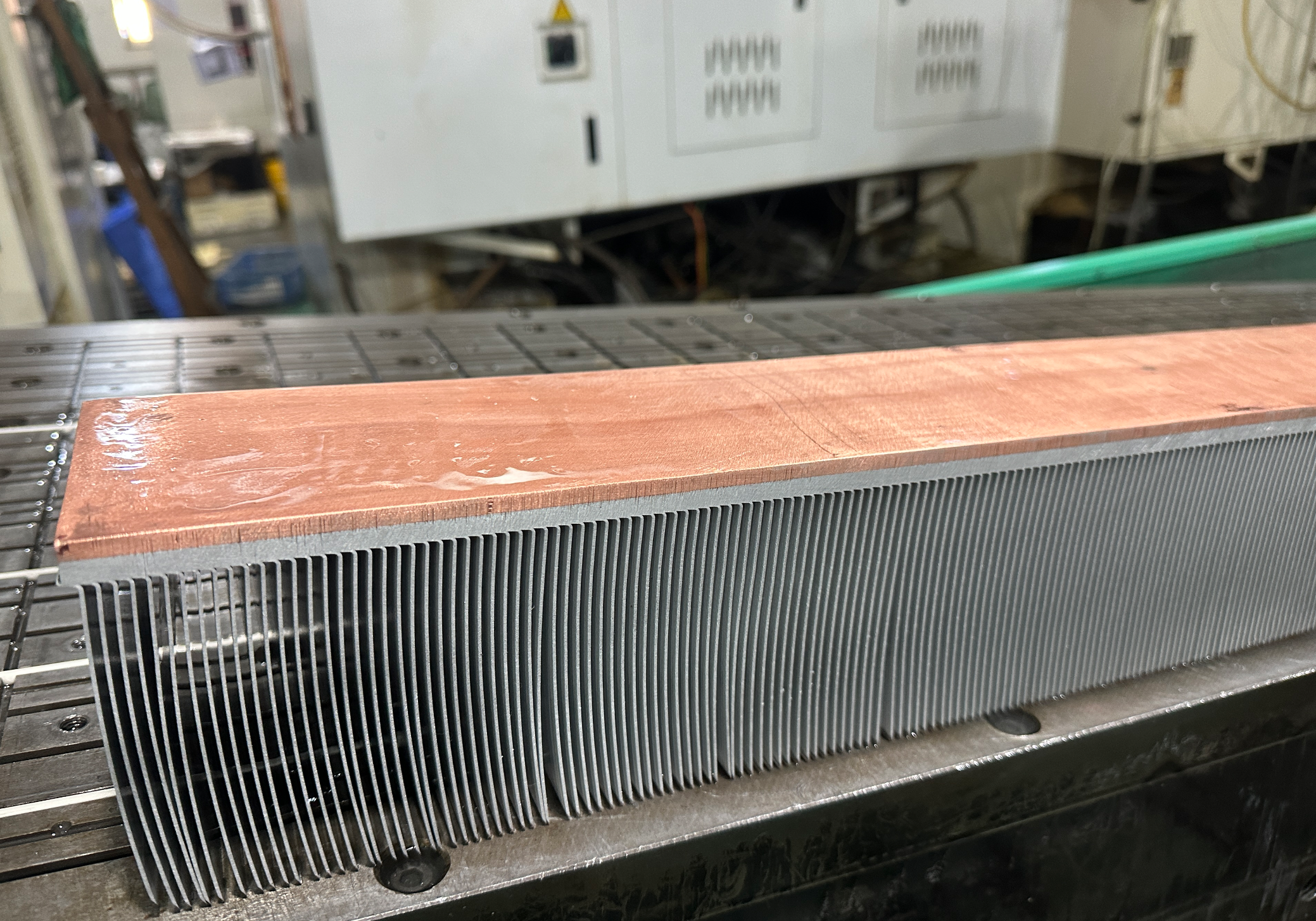

T-Shaped Heat Sink and Forced Convection Module: A heat sink is integrated at one end of the aluminum plate (heat convergence end) to form the “vertical edge” part of the T-shaped structure. The heat sink adopts a dense fin design, and the fin material is copper or aluminum alloy with excellent thermal conductivity to increase the heat dissipation area; at the same time, small axial fans are configured to build a forced convection heat dissipation system. The fan accelerates air flow to quickly dissipate the heat on the surface of the heat sink to the external environment.

(II) Working Principle: Efficient Heat Transfer Process Based on Phase Change Heat Transfer

The working process of the T-shaped heat dissipation structure is based on the phase change heat transfer mechanism of heat pipes and the principle of directional heat conduction. It can be divided into three stages as a whole to realize efficient heat transfer and dissipation:

-

Heat Collection Stage: The heat generated by the operation of the heating elements inside the base station is transferred to the closely attached aluminum plate carrier through heat conduction. As an intermediate medium, the aluminum plate evenly diffuses the heat scattered in various areas to the entire plate surface.

-

Heat Convergence Stage: The heat on the aluminum plate is transferred to the evaporation section (hot end) of the embedded heat pipe through contact thermal resistance. The working fluid in the heat pipe absorbs heat and quickly evaporates and vaporizes to form high-temperature and high-pressure steam. Due to the pressure difference inside the pipe, the steam quickly flows to the condensation section of the heat pipe (located at the heat convergence end of the aluminum plate and connected to the heat sink), realizing rapid directional heat conduction. This process uses the latent heat of phase change of the working fluid to transfer heat, and the heat conduction efficiency is far higher than that of solid metals such as pure copper and aluminum alloy, which can be dozens or even hundreds of times higher.

-

Heat Dissipation Stage: After the high-temperature steam in the condensation section of the heat pipe contacts the heat sink, it releases the latent heat of vaporization and condenses into liquid working fluid. The liquid working fluid flows back to the evaporation section under the capillary force of the wick, completing the heat transfer cycle inside the heat pipe. The heat absorbed by the heat sink is transferred to the surface of the dense fins. At this time, the forced convection module is started, and the fan accelerates the air flow over the fin surface to form strong air convection, which quickly takes away the heat on the fins and finally realizes efficient dissipation of heat inside the sealed cavity.

III. Advantages of T-Shaped Heat Pipe Heat Dissipation Structure and Adaptability to Application Scenarios

(I) Core Advantages: Breaking Through the Bottleneck of Traditional Heat Dissipation

Compared with the traditional die-casting fin heat dissipation solution, the T-shaped heat pipe embedded heat dissipation structure has significant advantages in heat dissipation efficiency, structural flexibility, environmental adaptability, etc., which are specifically reflected in the following points:

-

Significantly Improved Heat Dissipation Efficiency: With the phase change heat transfer characteristics of heat pipes, the heat conduction speed is far higher than that of traditional aluminum alloy shells. It can quickly converge the scattered heat in the sealed cavity to the heat sink, and then realize efficient dissipation through forced convection. Compared with the traditional passive heat dissipation scheme, the heat dissipation efficiency can be improved by more than 40%, which can effectively solve the problem of local hotspots in high-power density base stations.

-

Compact Structure, Adaptable to Sealed Environments: The structure uses an aluminum plate as the basic carrier, and the embedded heat pipe design does not occupy extra space. The T-shaped layout can integrate the heat sink at the edge of the base station shell or the reserved heat dissipation area without damaging the sealed structure, perfectly adapting to the IP65/IP67 protection level requirements of the base station. At the same time, the combined structure of aluminum plate and heat pipe is light in weight, meeting the lightweight design requirements of the base station.

-

Flexible Heat Conduction Path: Heat pipes can be flexibly arranged according to the layout of heating elements inside the base station, and can even be bent or flattened to adapt to complex spaces, realizing “point-to-point precision heat transfer” of heat, quickly exporting heat deep in the cavity, and solving the problem of single heat conduction path in traditional heat dissipation solutions.

-

Strong Environmental Adaptability: The introduction of the forced convection module makes the heat dissipation effect no longer dependent on the external natural wind speed, and can still operate stably under extreme working conditions such as high temperature and no wind. At the same time, both heat pipes and aluminum plates have good weather resistance, and can still maintain stable heat transfer performance after high-low temperature cycle testing, which can adapt to the base station deployment requirements in complex outdoor environments.

(II) Adaptability to Application Scenarios: Covering Various Base Station Heat Dissipation Needs

With its excellent comprehensive performance, the T-shaped heat pipe embedded high-efficiency heat dissipation structure can be widely adapted to the thermal management needs of various communication base stations, especially suitable for the following scenarios:

-

High-Power Density 5G/6G Base Stations: As 5G base stations evolve towards millimeter wave and low latency directions, and the pre-research of 6G technology advances, the power density of base station equipment continues to increase. Traditional heat dissipation solutions are difficult to meet the needs. The T-shaped heat pipe structure can realize rapid dissipation of high heat flux density heat through efficient heat transfer and forced convection, ensuring stable operation of equipment.

-

Outdoor Extreme Environment Base Stations: Base stations deployed in extreme environments such as high-temperature deserts, high humidity in coastal areas, and alpine regions have higher sealing requirements and large ambient temperature fluctuations. The structure has good weather resistance and stable heat dissipation performance, which can effectively cope with thermal management challenges under extreme working conditions.

-

Miniaturized and Integrated Base Stations: With the increase in the deployment density of base stations in urban dense areas, miniaturized and integrated base stations have become a development trend. Their internal space is limited, and heat dissipation is more difficult. The compact and lightweight design of the structure can adapt to the space needs of miniaturized base stations and realize efficient heat dissipation at the same time.

-

Heat Dissipation Upgrade and Renovation of Existing Base Stations: For existing 4G or early 5G base stations with problems such as insufficient heat dissipation and high equipment failure rate, they can be upgraded and renovated by adding the T-shaped heat pipe heat dissipation structure without replacing the entire shell, which reduces the upgrade cost and extends the equipment service life.

IV. Conclusion

The stable operation of communication base stations is the core premise to ensure the smoothness of communication networks. As the “cooling heart” of base station equipment, the technological innovation and optimization upgrade of the thermal management system are crucial. The traditional die-casting fin heat dissipation solution has played an important role in base stations with low power and simple environments, but with the iteration of communication technology and the increase in base station operation load, it has been difficult to meet the efficient heat dissipation needs under high power density and sealed environments.

The innovative solution of “aluminum plate embedded heat pipes + T-shaped structure heat dissipation” proposed in this paper realizes the rapid collection, directional conduction and efficient dissipation of heat inside the sealed base station by integrating the phase change heat transfer advantages of heat pipes and the structural optimization of T-shaped layout, breaking through the bottleneck of traditional heat dissipation solutions. The structure has the characteristics of high heat dissipation efficiency, compact structure, strong environmental adaptability and wide application scenarios. It can not only meet the thermal management needs of current 5G base stations, but also provide a feasible technical path for the thermal management of future 6G base stations and more advanced communication infrastructure.

In the future, with the continuous progress of materials science and manufacturing processes, the performance of this heat dissipation structure can be further optimized, such as adopting nano-reinforced aluminum matrix composites with higher thermal conductivity, optimizing the arrangement of heat pipes and the structure of wicks, and introducing intelligent temperature-controlled forced convection modules, so as to continuously improve heat dissipation efficiency and reliability and escort the high-quality development of the communication industry.